Multifunctional fuel cell on-line testing printed circuit board

A technology for printed circuit boards and fuel cells, which is used in the measurement of electricity, measurement devices, and measurement of electrical variables, etc., can solve the problem of inability to accurately reflect the distribution of water and heat in fuel cell partitions, electrochemical reaction conditions, and mass transfer and heat transfer phenomena, and test partitions. There are few parameters and the inability to measure the distribution of current density, temperature and AC impedance of the fuel cell, etc., to achieve the effect of simple structure, high degree of integration and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

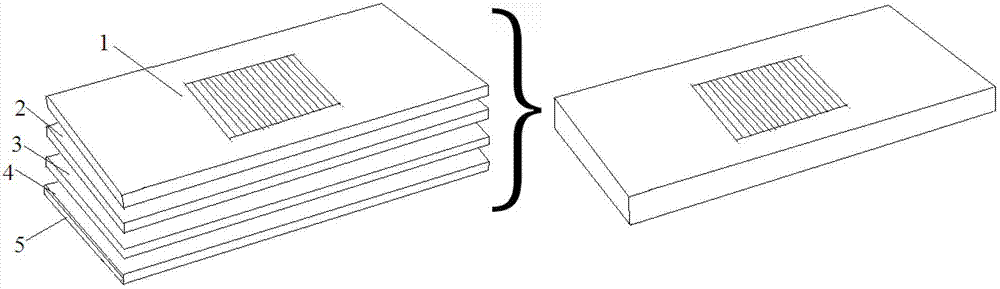

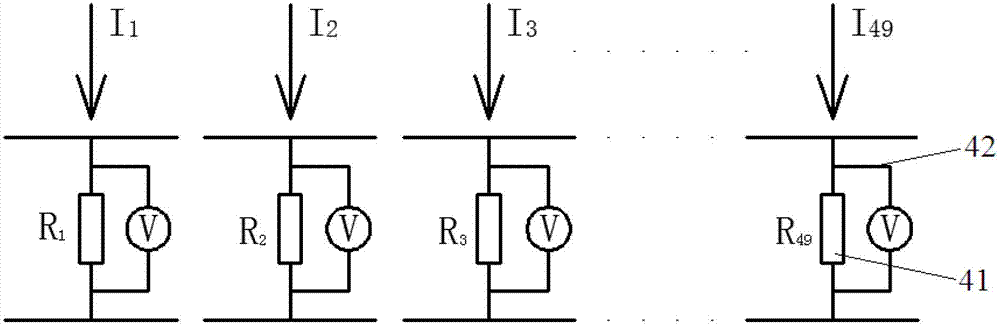

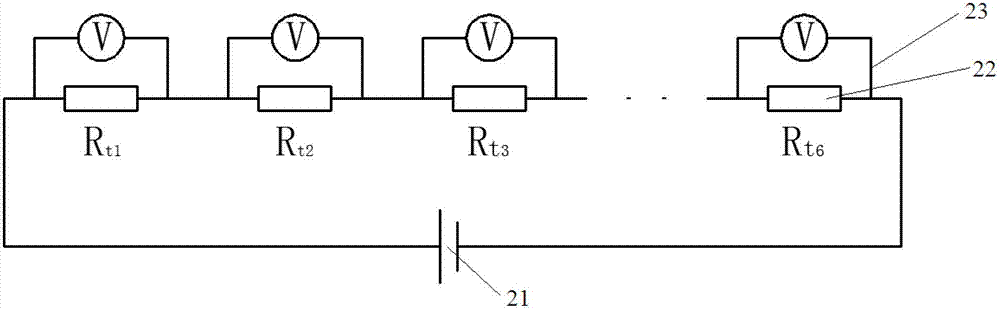

[0033] A fuel cell multifunctional on-line test printed circuit board, the printed circuit board cooperates with data acquisition and analysis modules, and can be used for online measurement of the current density distribution, temperature distribution and AC impedance of the fuel cell. The fuel cell includes an anode plate and a cathode plate. , MEA membrane and hydrogen flow channel. Such as figure 1 As shown, the printed circuit board includes a partitioned flow field layer 1, a temperature test layer 2, an impedance test layer 3, a current density test layer 4, and a current collection and water flow field layer 5 arranged sequentially from top to bottom. The partitioned flow field layer 1, the impedance test layer 3, the current density test layer 4, the current collection and water flow field layer 5, and the fuel cell are connected in sequence to form a closed loop.

[0034] The upper surface of the partitioned flow field layer 1 is provided with an anode flow field th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com