High hardness material laser cladding process method for roller work surface

A technology of laser cladding and process method, which is applied in the direction of metal material coating process, coating, etc., can solve the problems of coarse grain structure, poor composition uniformity, and easy cracking of the welding layer, and achieve a dense and fine structure of the welding layer. The effects of modernization, high production efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

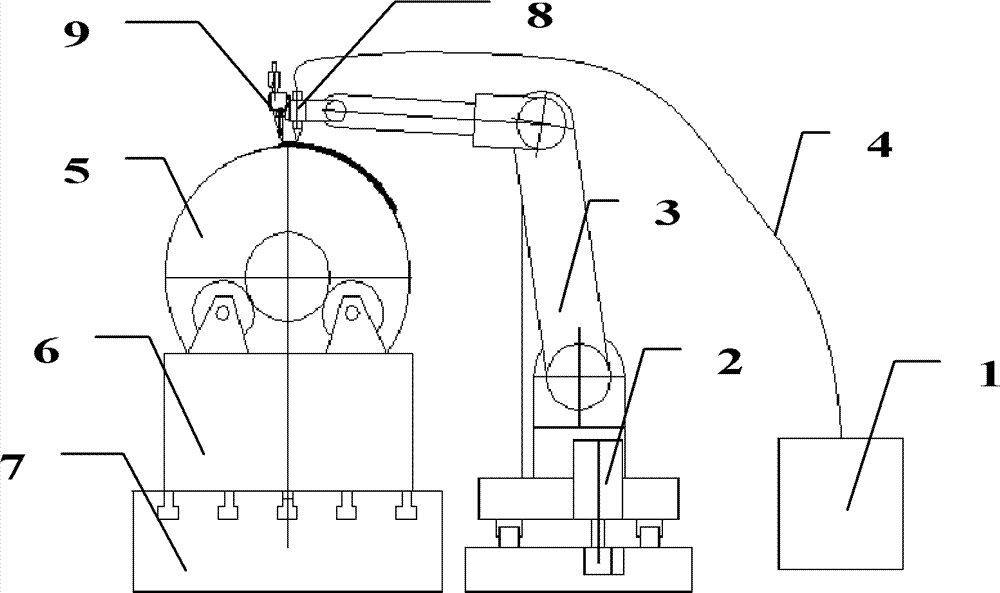

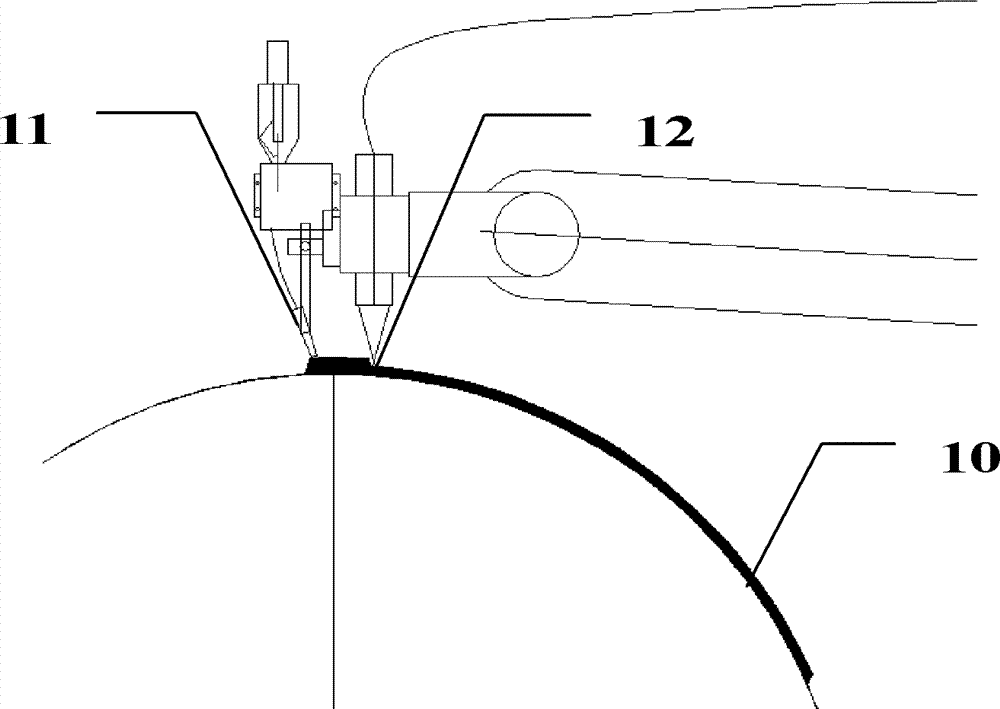

Method used

Image

Examples

Embodiment 1

[0037] The working surface of a cast steel roll made of 165CrNiMo was severely damaged, and the specification of the roll was The laser cladding repair treatment is carried out on the roller by adopting the technological method of the present invention, and all indexes after the repair meet the use standard of the roller on the machine. During processing:

[0038] 1) Laser cladding process parameters are: laser power 10KW, scanning speed 1000mm / min, spot size 15×1.5mm, overlap rate 50%, single-pass cladding thickness 3.5mm, cladding width 15mm, total cladding thickness is 35mm, the cladding material is iron-based alloy powder.

[0039] 2) The heat treatment process is as follows: roll preheating temperature 580±20°C, heating rate 120°C / hour, holding time 2 hours; heating and holding temperature 500±20°C during cladding; 380±20°C, 5 Hours of heat preservation, and then naturally cooled to room temperature.

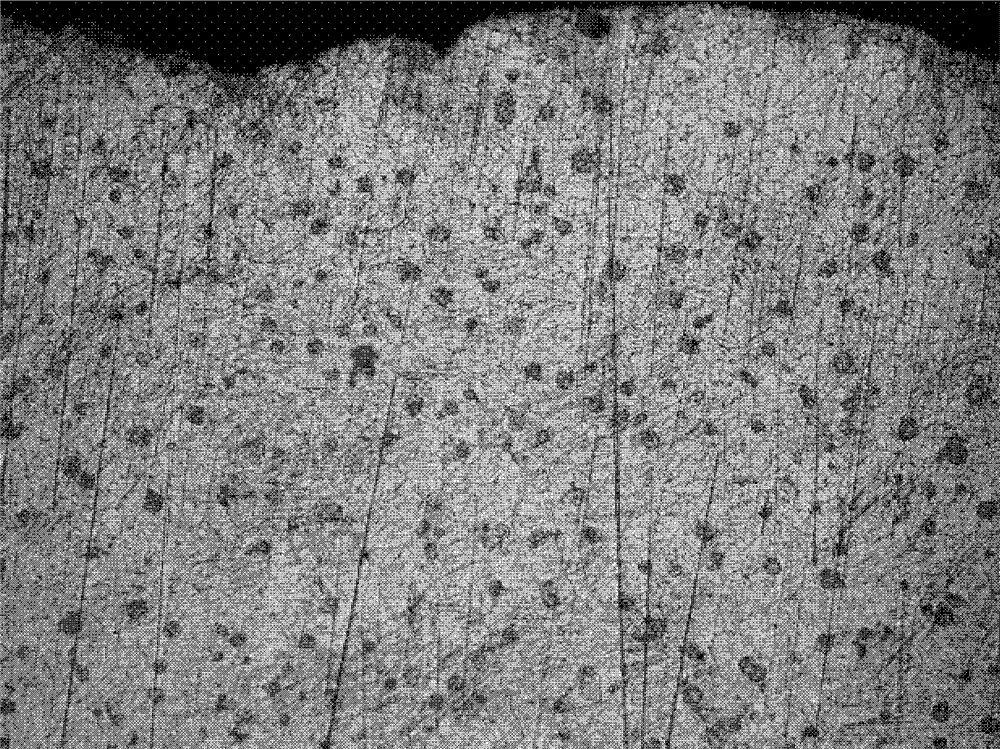

[0040] In this embodiment, the hardness of the welding layer aft...

Embodiment 2

[0042] The difference from Example 1 is:

[0043] The material of a roll is 70Mn2, and the specification is Using the process of the present invention to carry out laser cladding repair on the working surface of the roller, during the processing:

[0044] 1) Laser cladding process parameters are: laser power 6KW, scanning speed 600mm / min, spot size 15×1.5mm, overlap rate 40%, single cladding thickness 2.5mm, cladding width 15mm, total cladding thickness is 25mm.

[0045] 2) The heat treatment process is as follows: roll preheating temperature 520±20°C, heating rate 150°C / hour, holding time 1 hour; heating and holding temperature 450±20°C during cladding; 380±20°C, 4 Hours of heat preservation, and then naturally cooled to room temperature.

[0046] In this example, after the roll is repaired by laser cladding, a good alloy welding layer is obtained, and the hardness of the welding layer reaches HRC61-64. Meet the use requirements of the roller machine.

[0047] Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com