Preparation method of straw pulp

A technology for straw pulp and grasses, which is applied in the field of preparation of straw pulp for papermaking, can solve the problems of low extraction rate of black liquor, low pulping efficiency, limited wood resources, etc., and achieves the effect of improving the efficiency of delignification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

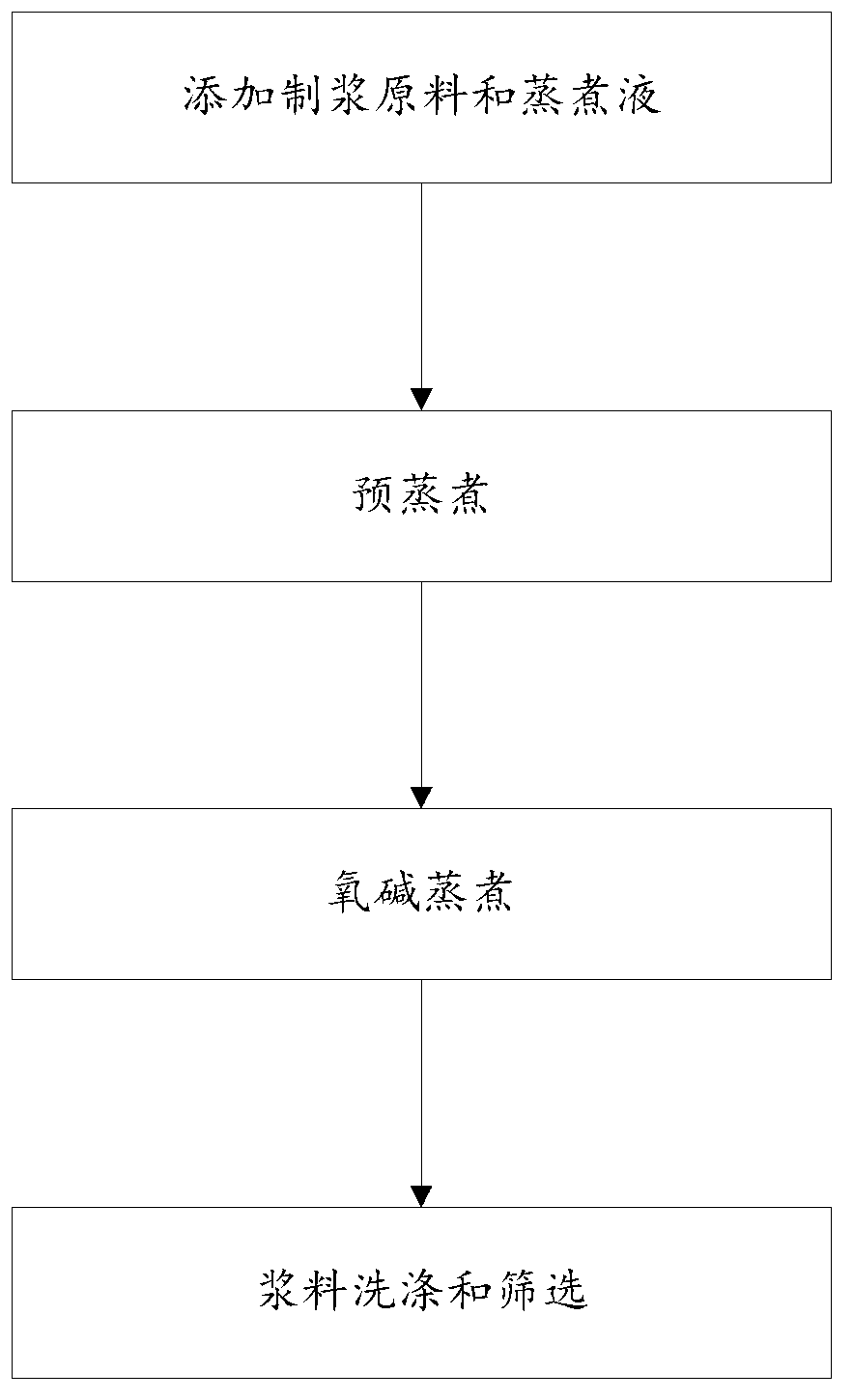

Method used

Image

Examples

Embodiment 1

[0035] The straw is cut short and dusted, then washed to remove debris and then dehydrated. The dehydrated rice straw is sent into the cooking equipment, and at the same time, the cooking liquid preheated to 80° C. is added and mixed evenly with it, and the weight ratio of the rice straw to the cooking liquid is 1:3.5. The cooking liquid is an aqueous solution of sodium hydroxide and magnesium sulfate, the consumption of sodium hydroxide is 13% of the weight of rice straw, and the consumption of magnesium sulfate is 2% of the weight of rice straw. After the charging is finished, the cooking equipment is sealed, and oxygen is introduced into it to keep the oxygen pressure in the cooking equipment at 0.5 MPa. The cooking equipment is heated, and the rice straw is steamed at 130° C. for 90 minutes with the cooking liquid. After the cooking is finished, pump the black liquor with low temperature and concentration into the system to lower the temperature in the digester below the ...

Embodiment 2

[0038] Repeat Example 1, and the partial reaction parameters are adjusted as follows: the weight ratio of rice straw and cooking liquid is 1:6, wherein the consumption of sodium hydroxide is 20% of rice straw weight, the consumption of magnesium sulfate is 0.7% of rice straw weight, cooking equipment The oxygen pressure in the oven was maintained at 1MPa, the cooking temperature was 90°C, and the cooking time was 240 minutes. After cooking, the slurry is directly sprayed.

[0039]In this example, the various index results of the prepared straw pulp are: fine pulp yield 54.5%, kappa number 7.7, whiteness 59%ISO, viscosity 850mL / g.

Embodiment 3

[0041] The straw is cut short and dusted, then washed to remove debris and then dehydrated. The dehydrated rice straw is sent into the cooking equipment, and at the same time, the cooking liquid preheated to 90° C. is added and mixed evenly with it, and the weight ratio of the straw to the cooking liquid is 1:4. The cooking liquid is an aqueous solution of sodium hydroxide, sodium sulfide and magnesium sulfate, the consumption of sodium hydroxide and sodium sulfide is 16% of the weight of rice straw, and the consumption of magnesium sulfate is 0.25% of the weight of rice straw. After the charging is finished, the cooking equipment is sealed, and the rice straw is precooked at 90° C. for 60 minutes with the cooking liquid. After completing the precooking, feed oxygen into the cooking equipment to keep the oxygen pressure in the cooking equipment at 0.3MPa. Heat the cooking equipment, and cook the rice straw with the cooking liquid at 110° C. for 30 minutes. The subsequent tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com