Composite machine set of steam compression type refrigeration device and heating device, and use thereof

A vapor compression, refrigeration and heating technology, applied in the direction of refrigerators, refrigeration components, heating and refrigeration combinations, etc., can solve the problem of not being used, the heating and hot water production in winter cannot meet the requirements, and the cooling capacity is not being used, etc. problems, to achieve the effect of saving expenses, slowing climate warming, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example ( 1

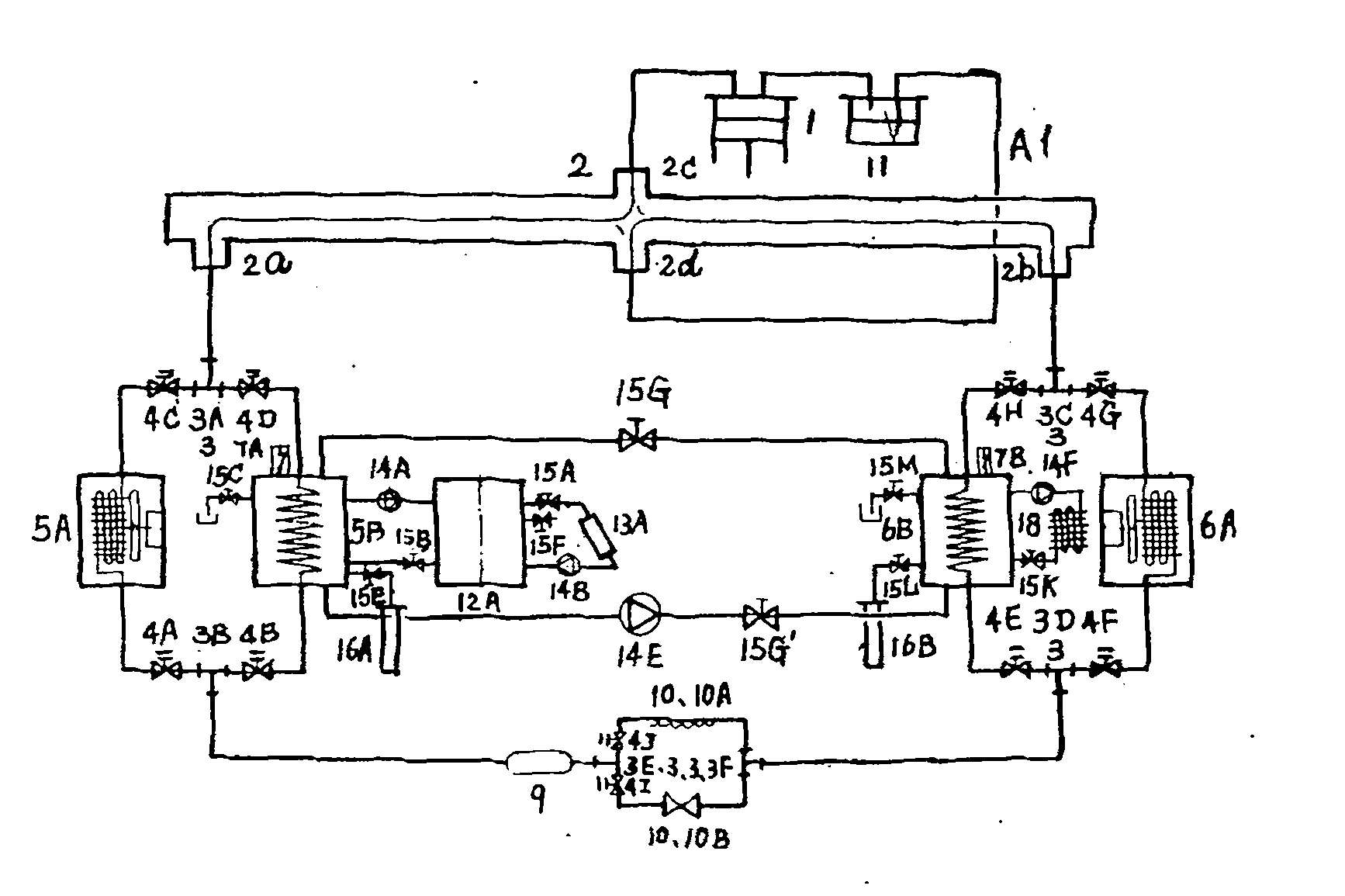

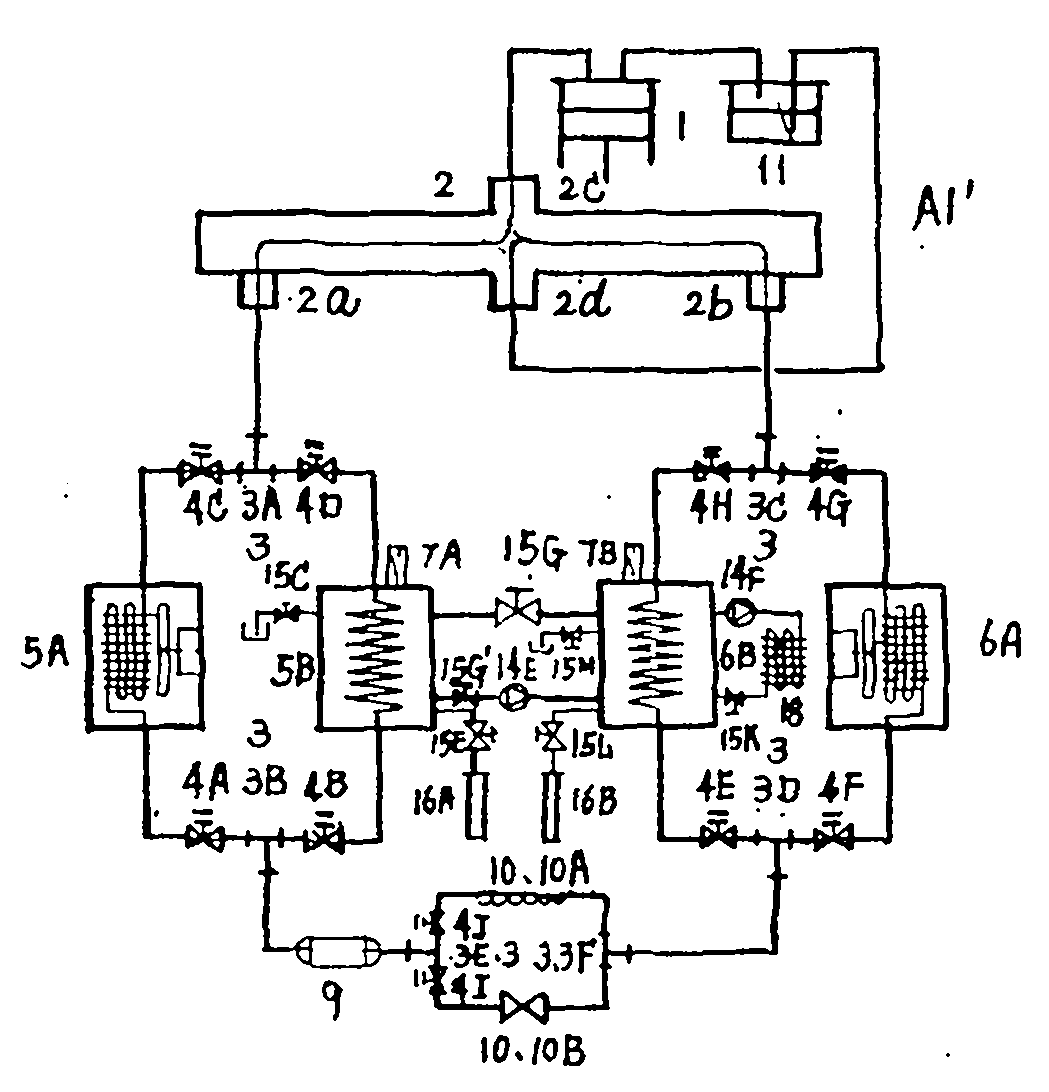

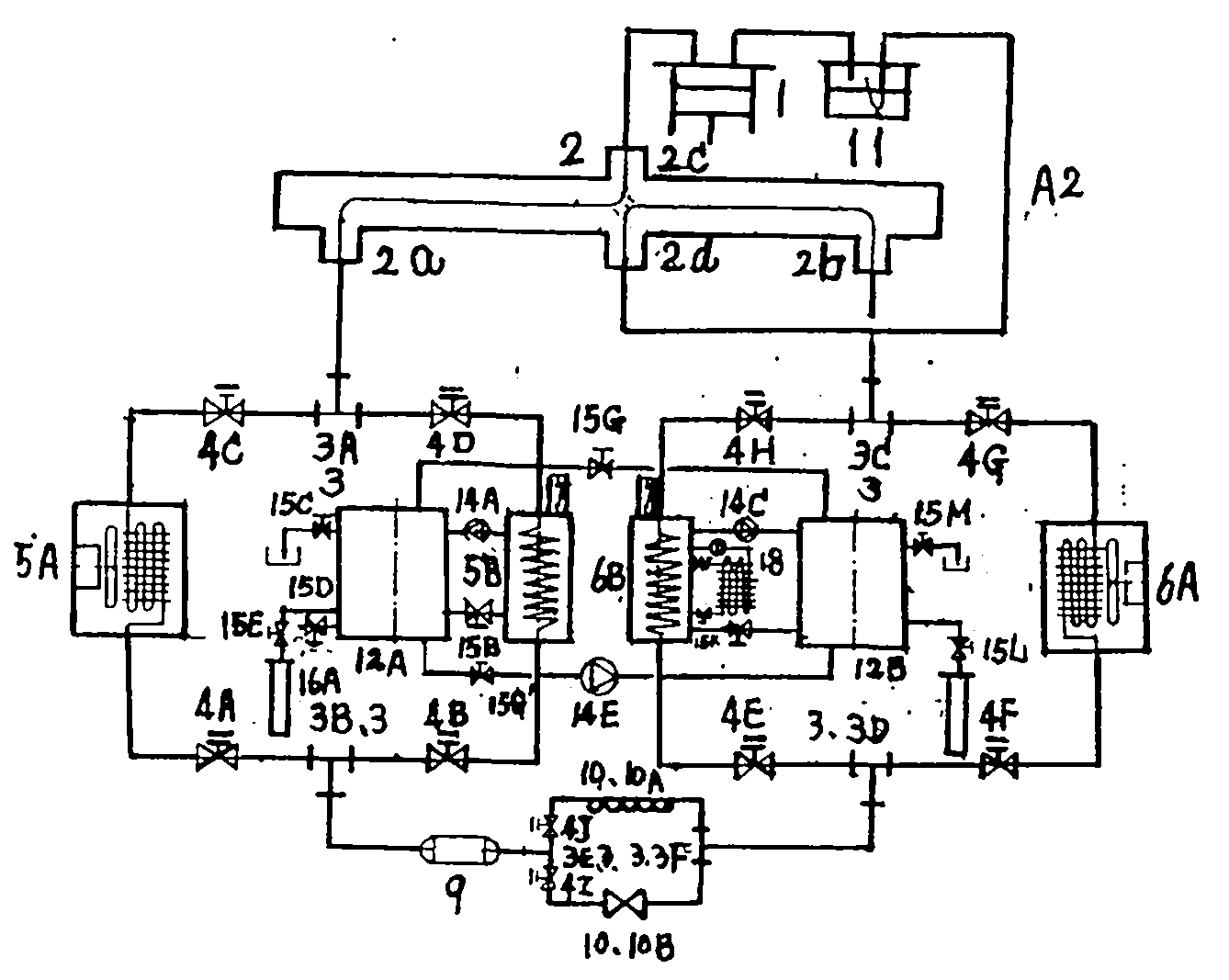

[0033]The vapor compression refrigeration system A0 of the existing air conditioner is composed of a compressor 1, the middle upper interface 2C of the four-way electromagnetic reversing valve 2 to the left interface 2a, an air-cooled condenser 5A, a dry filter 9, and a throttle valve. 10. The air energy evaporator 6A, the right port 2b of the four-way electromagnetic reversing valve 2 to the middle lower port 2d and the gas-liquid separator 11 are sequentially sealed and connected with pipelines to form a vapor compression refrigeration system A0, an implementation case of the present invention (1) It is the first vapor compression refrigeration and heating composite system A1 of the composite unit of vapor compression refrigeration equipment and heating equipment, as shown in Figure (1), its structural features are: the vapor compression refrigeration system In A0, between the left interface 2a of the four-way electromagnetic reversing valve 2 and the left interface of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com