Coke oven group oxynitride detection method

A technology for nitrogen oxides and detection methods, which is applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as increasing the burden on enterprises and increasing equipment investment, and achieves the effect of saving money, reducing equipment operating costs, and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the specific embodiment of the present utility model is described in further detail.

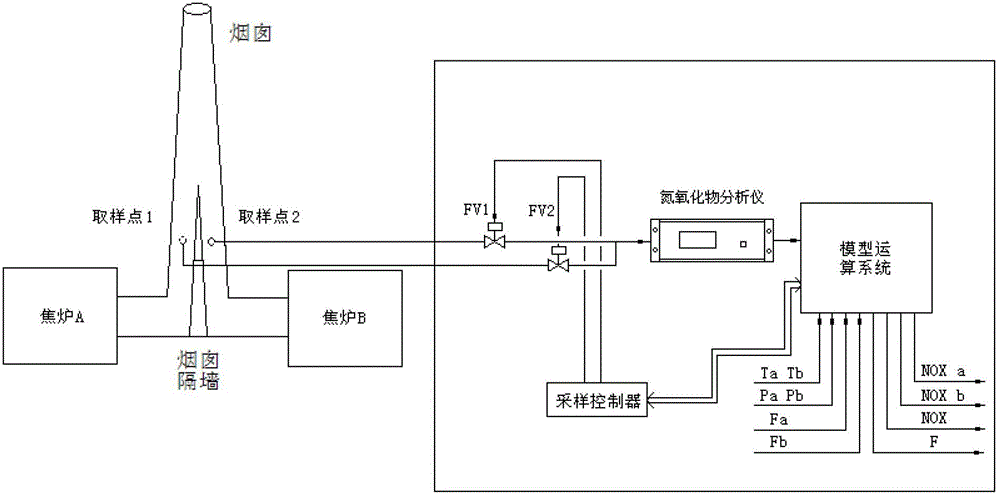

[0021] See figure 1 , a coke oven group nitrogen oxide detection system is composed of a stainless steel sampling device, an intermittent sampling control valve group, a sampling controller, a nitrogen oxide analyzer, and a model calculation system.

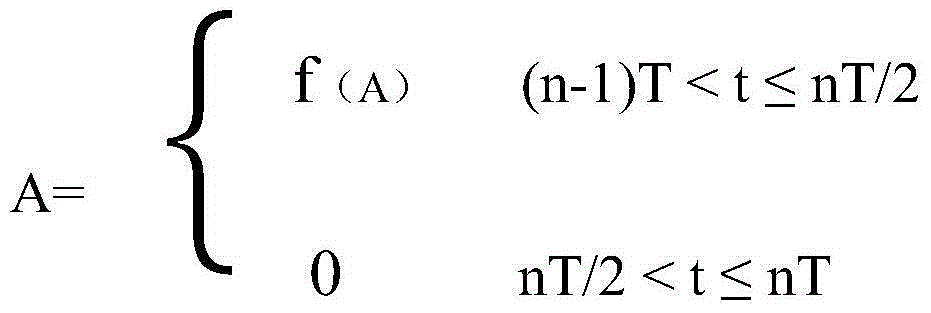

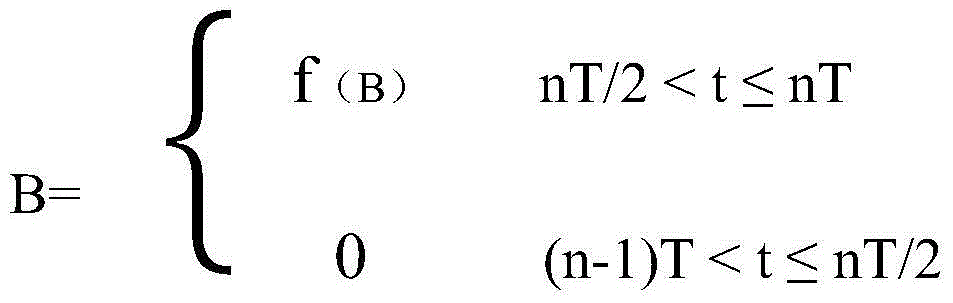

[0022] The sampling controller controls the intermittent sampling control valve group. It uses timing division as the control mechanism and adopts the intermittent sampling method instead of the traditional continuous sampling method. Such a sampling control system can realize the measurement of multiple detection points by a single detection device. Through the intermittent sampling of the control valve group, the nitrogen oxide analyzer can accurately measure the nitrogen oxides in the measured gas. The model calculation system sends control parameters to the sampling controller to coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com