Manufacturing method of COA array substrate, array substrate and display device

An array substrate and substrate technology, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of low production efficiency, high cost, and complex array substrate preparation methods, and achieve low cost, good fluidity, and cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] combine image 3 , Figure 4 , Figure 5 , this embodiment provides a method for preparing a COA array substrate, including:

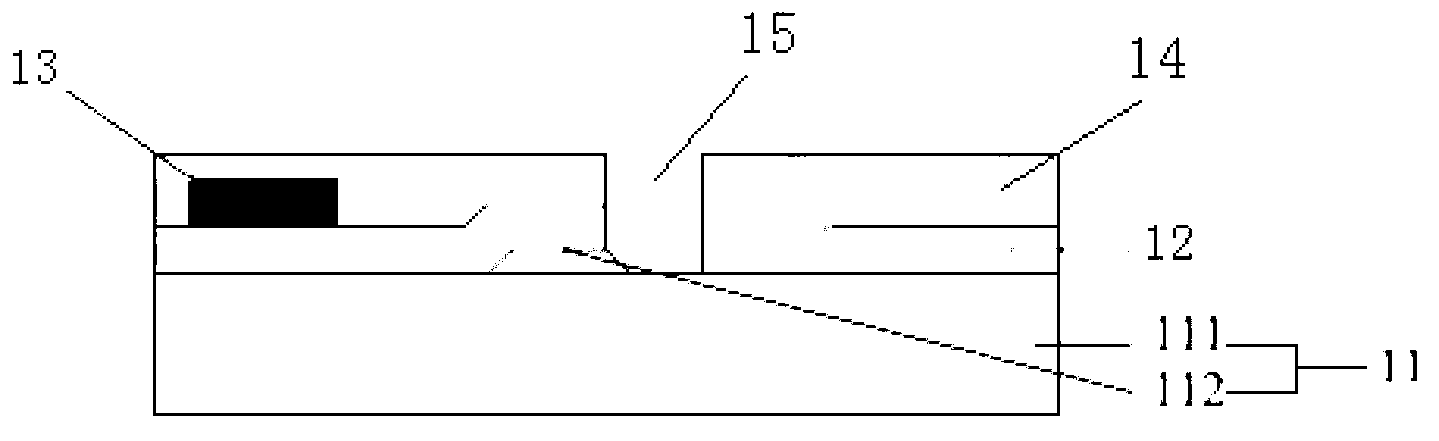

[0026] Step 1, first fabricate thin film transistors 112, metal wires and other components on the substrate 111, complete the fabrication of the TFT substrate 11, and make a protective layer 12 on the TFT substrate 11 to protect the backplane.

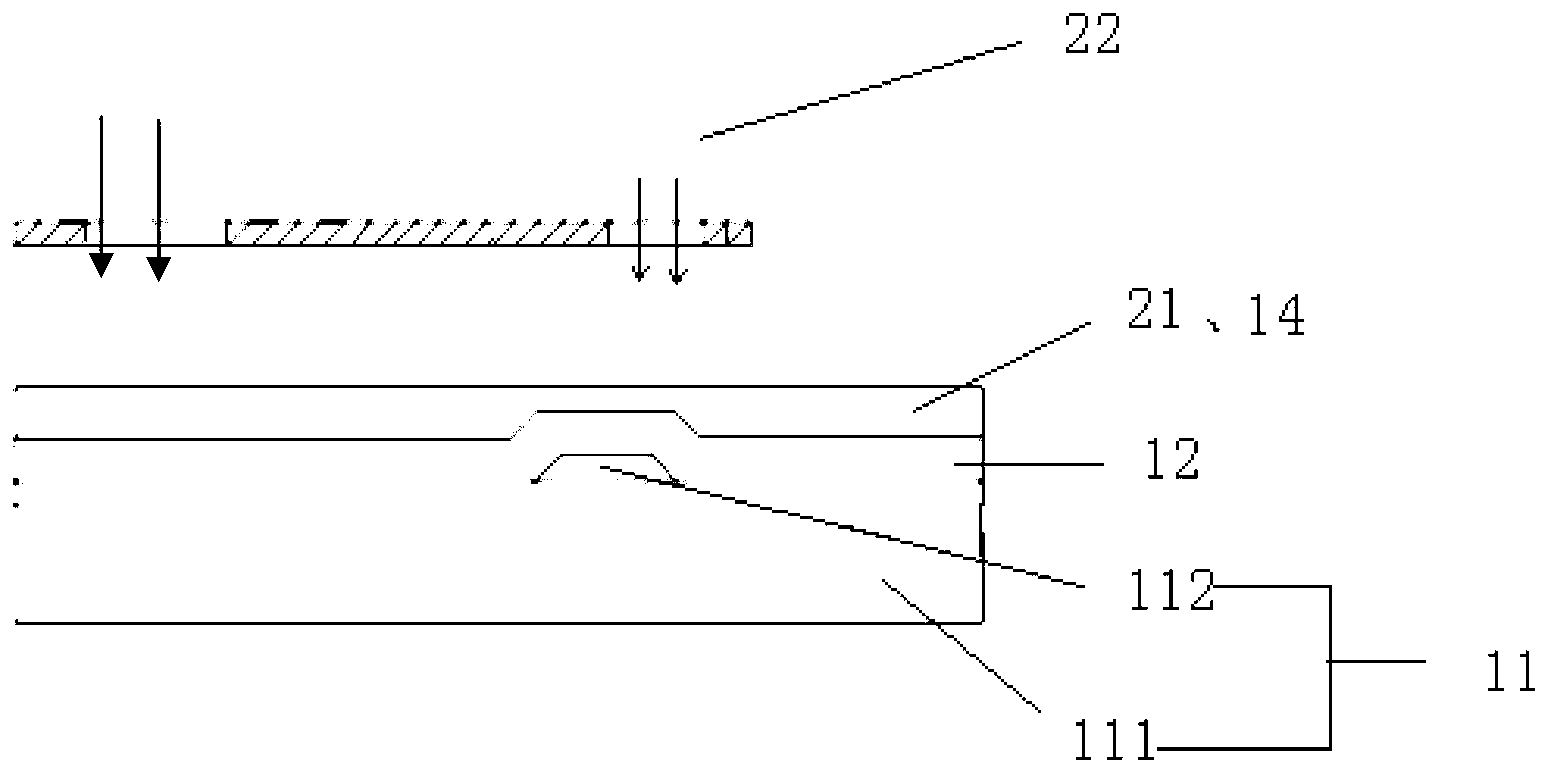

[0027] Step 2, coat the photoresist layer 21 on the protective layer 12, and use the mask plate 22 to expose the photoresist layer 21 through the patterning process. The exposed area is the color pixel area. After the exposure, the color pixel area is developed and post-baked A color filter receiving hole 32 is fabricated, and the photoresist layer 21 serves as a planarization layer 14 at the same time.

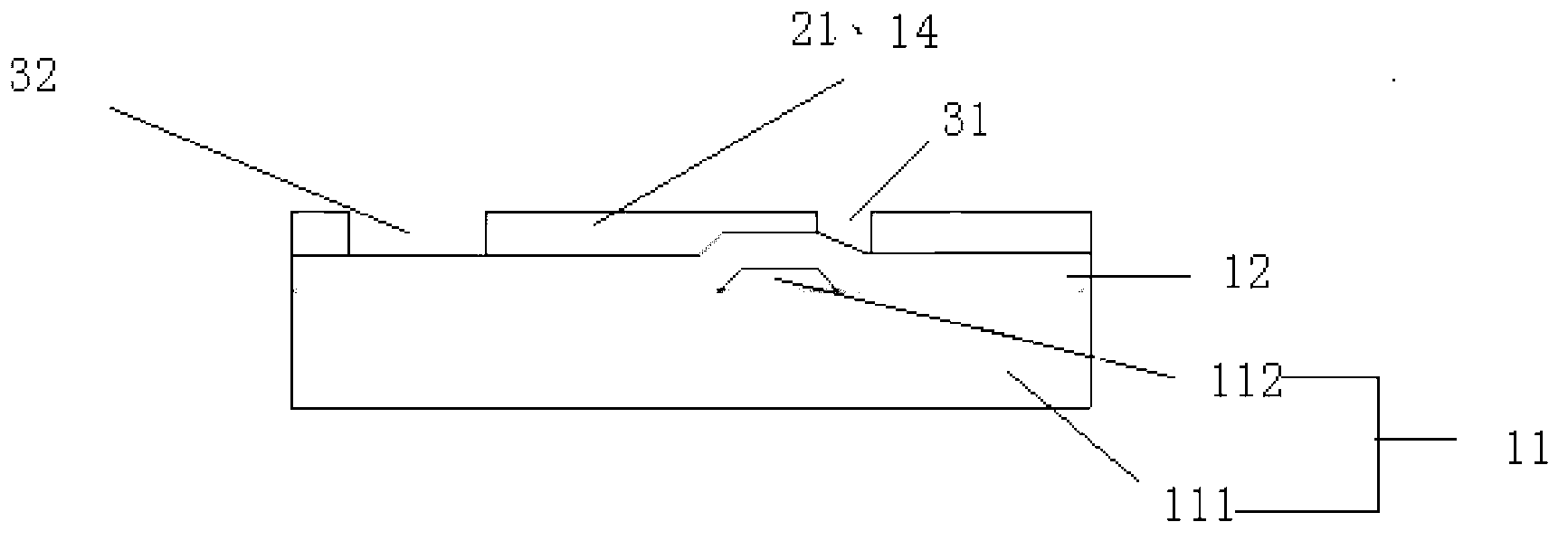

[0028] Step 3, adding dyes to the color filter receiving holes 32 to form the color filter layer 13 . Wherein, since the step difference of the photoresist layer 21 is very small, the photoresist la...

Embodiment 2

[0041] This embodiment provides an array substrate, including a photoresist layer 21 on the protective layer 12, the photoresist layer 21 also serves as a planarization layer 14, and a color filter receiving hole 32 is formed therein, the color filter receiving hole 32 is formed with a color filter layer 13 . The photoresist serves as the planarization layer 14 at the same time, which can save costs during fabrication.

[0042] Preferably, the array substrate is an OLED substrate, and a via hole 15 is provided on the COA array substrate, and the anode is connected to the drain of the thin film transistor 112 on the OLED substrate through the via hole 15 . Of course, the OLED can also be arranged on the TFT substrate 11 , and the anode of the OLED is directly connected to the drain of the thin film transistor 112 , so the array substrate does not need to be provided with the via hole 15 .

[0043]Preferably, the array substrate is a TFT-LCD array substrate, the COA array subst...

Embodiment 3

[0046] This embodiment provides a display device, which includes the above-mentioned array substrate, and of course also includes structures such as an outer frame of a conventional display device.

[0047] Since the display device includes the above-mentioned array substrate, its manufacturing process is simple and the cost is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com