Surface coating with perfluorinated compounds as antifouling

A perfluorinated compound, anti-fouling technology, applied in anti-fouling/underwater coatings, devices for coating liquids on surfaces, coatings, etc., can solve problems such as not providing fouling solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

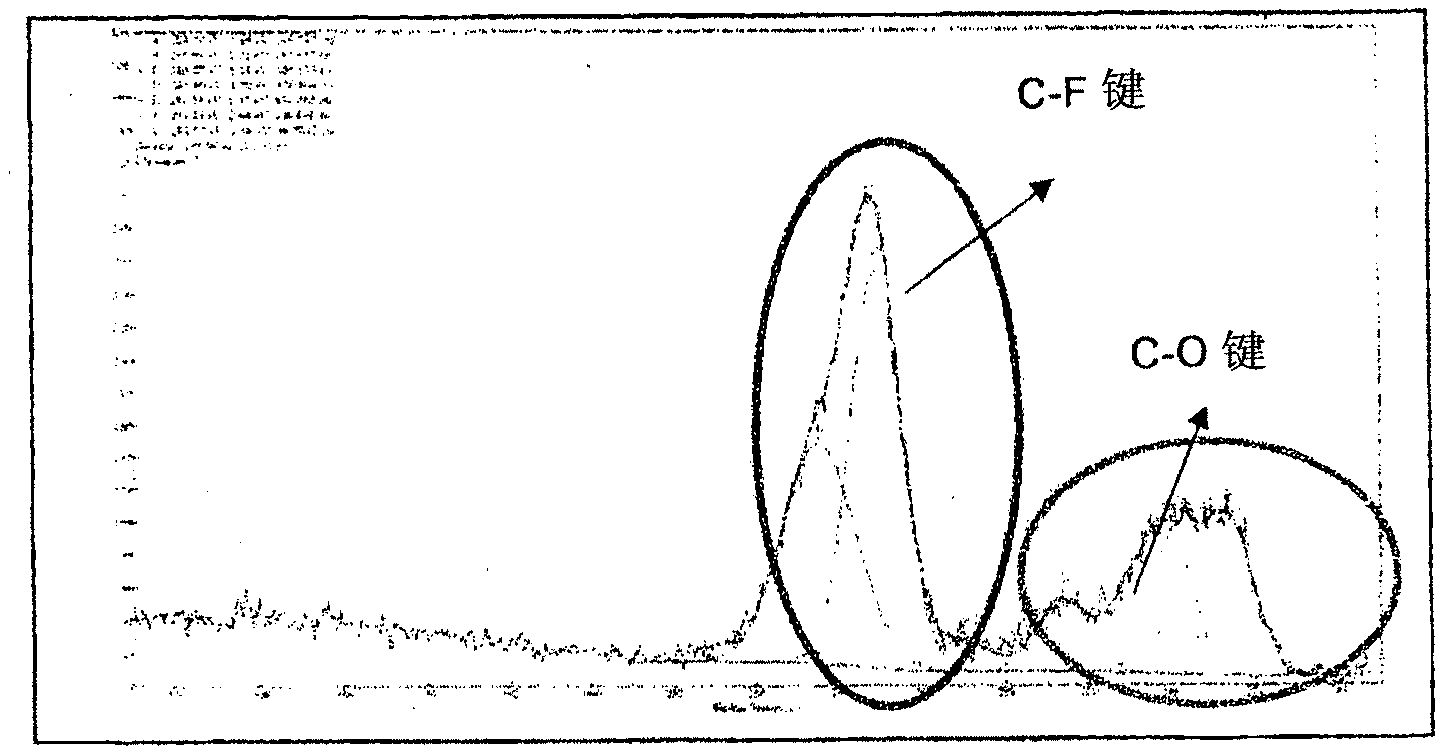

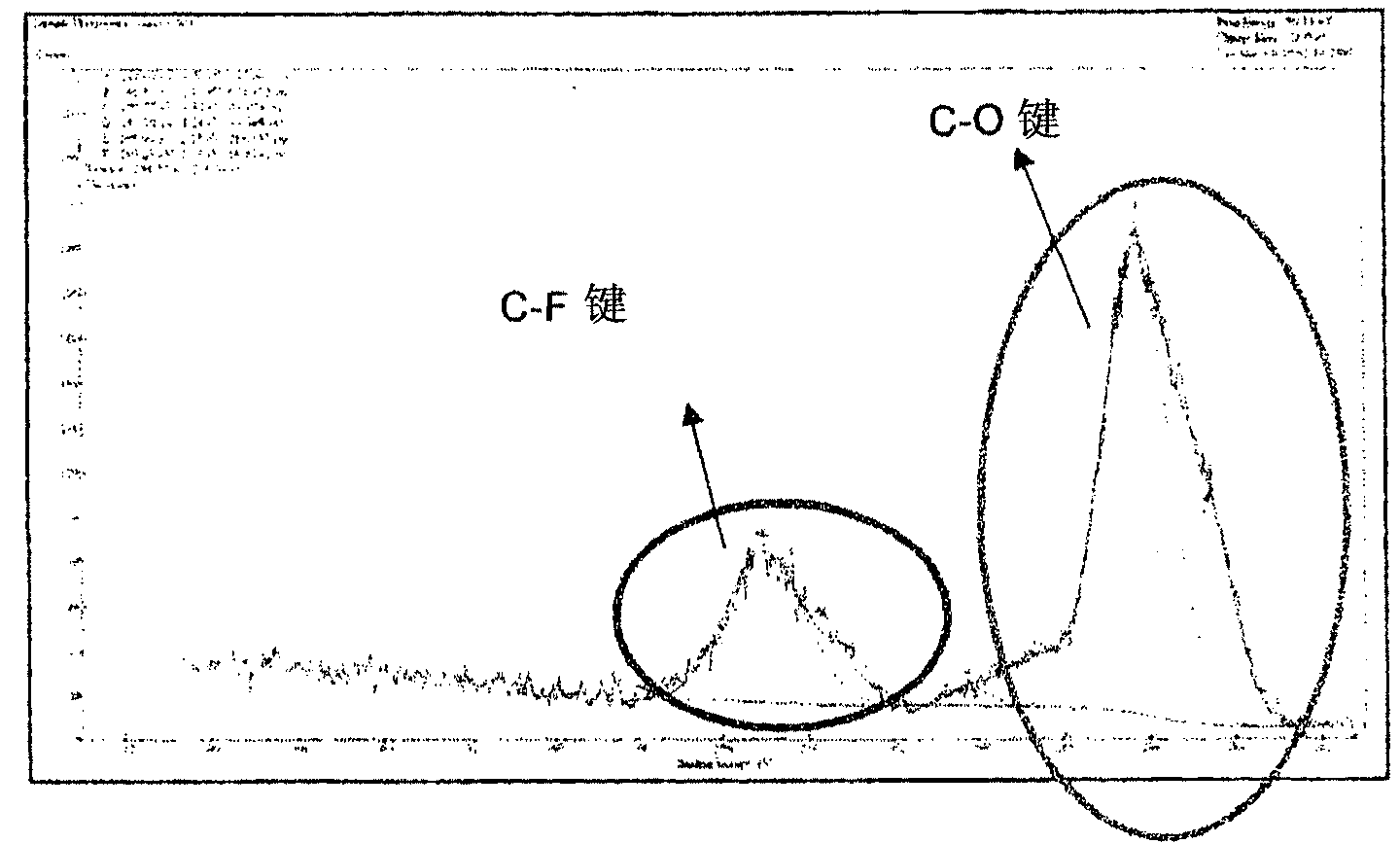

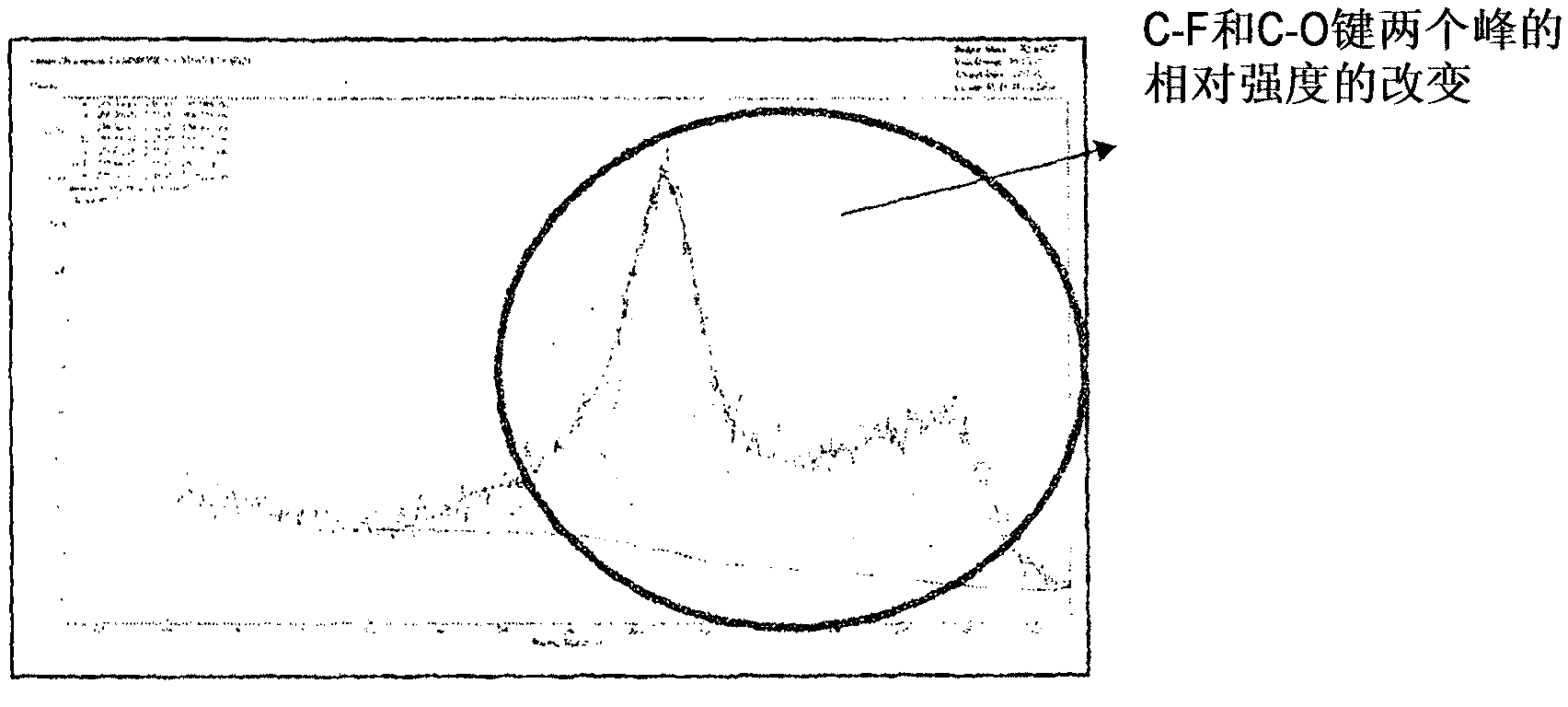

Image

Examples

Embodiment Construction

[0067] Experimental part

[0068] sample preparation

[0069] It is determined to use samples of carbon steel and stainless steel (AISI304 and AISI316). The coating is applied to a test sheet or sample measuring 2 cm x 1 cm. Some test samples were prepared in a suitable manner by an initial wash with water and acetone to remove coarser impurities on the samples before applying the coating, after which they were prepared by immersing them in CH 2 Cl 2 Medium for 1 min (while stirring with a magnetic stirrer) to bring the sample surface as close to perfect as possible.

[0070] This is done to increase the efficiency of the cleaning sample method by providing turbulent flow near the sample surface.

[0071] Coatings were also applied to unwashed samples in order to reproduce the industrial process as closely as possible. It has been found that there is no significant difference between the contact angles after coating and heating the samples, thus demonstrating that the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com