Method and device for surface inspection of strips

A technology for surface inspection and belt molding, which is used in measuring devices, length measuring devices, image data processing, etc., can solve the problems of high cost and many metal belt scraps, and achieve the effect of shortening inspection time and good visual environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

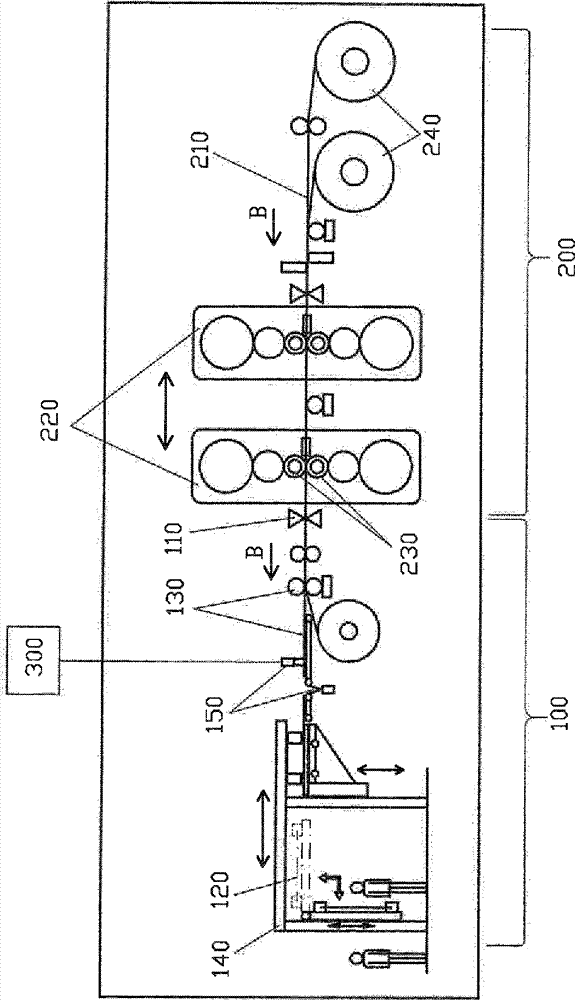

[0033] exist figure 1 shows the device 100 according to the invention coupled directly to a rolling train 200 . Metal strip 210 is fed from coil 240 in strip machine direction B to rolling stand 220 . The strip head of the metal strip 210 is guided through a rolling stand 220 and then adjusted to work rolls 230 , whereby the metal strip can be rolled. Strip heads that have not yet been rolled are separated and disposed of. By separating off the first strip, a new strip is produced for the metal strip 210 , which has been rolled by the work rolls. Immediately after the start of the rolling of the metal strip 210 , the separating device 110 separates the strip profile 120 / strip head from the metal strip 210 with a length that is less than twice the circumference of the work roll 230 . The length is freely chosen below this limit. If the strip 120 required for the surface inspection is separated, the metal strip is fed to a coiler and rolled by work rolls 230 to the desired ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com