Organic waste gas resource recycling device with plate type structure

A technology of organic waste gas and recovery device, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of low energy utilization rate, high cost, and large equipment footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

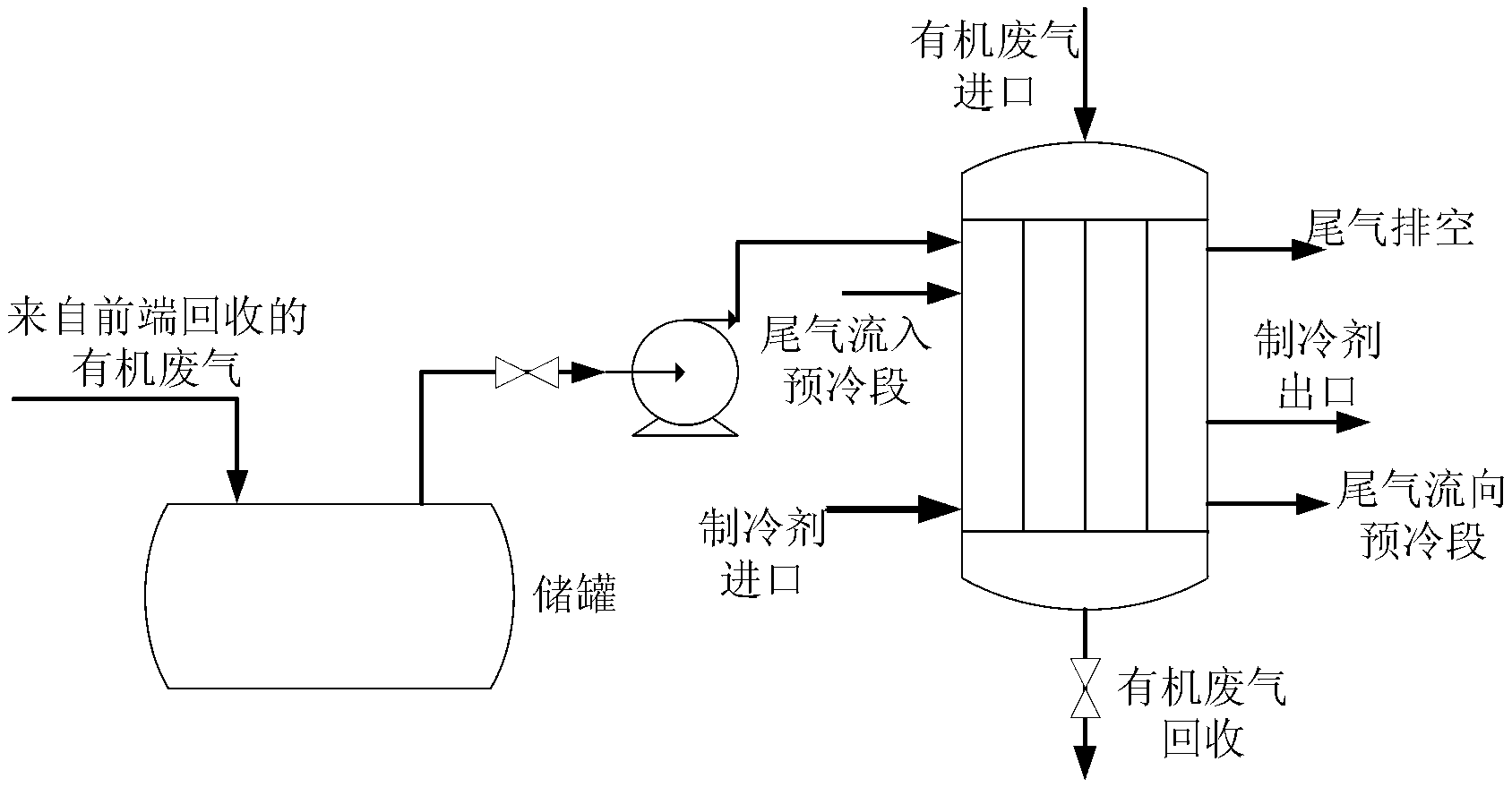

[0017] Refer to attached figure 1 , The waste gas from the front-end collection device of organic waste gas enters the core body of the recovery device through the pump, and performs countercurrent heat exchange with the refrigerant while being adsorbed by the adsorbent in the organic waste gas channel. The hydrocarbons contained in it are condensed and adsorbed on the adsorbent, and the purified tail gas is used as a pre-coolant and enters the channel of the pre-cooling section to exchange heat with the initial organic waste gas, and then is emptied from the tail gas outlet at the upper end of the device. After the adsorbent is saturated, the vacuum pump is started for desorption.

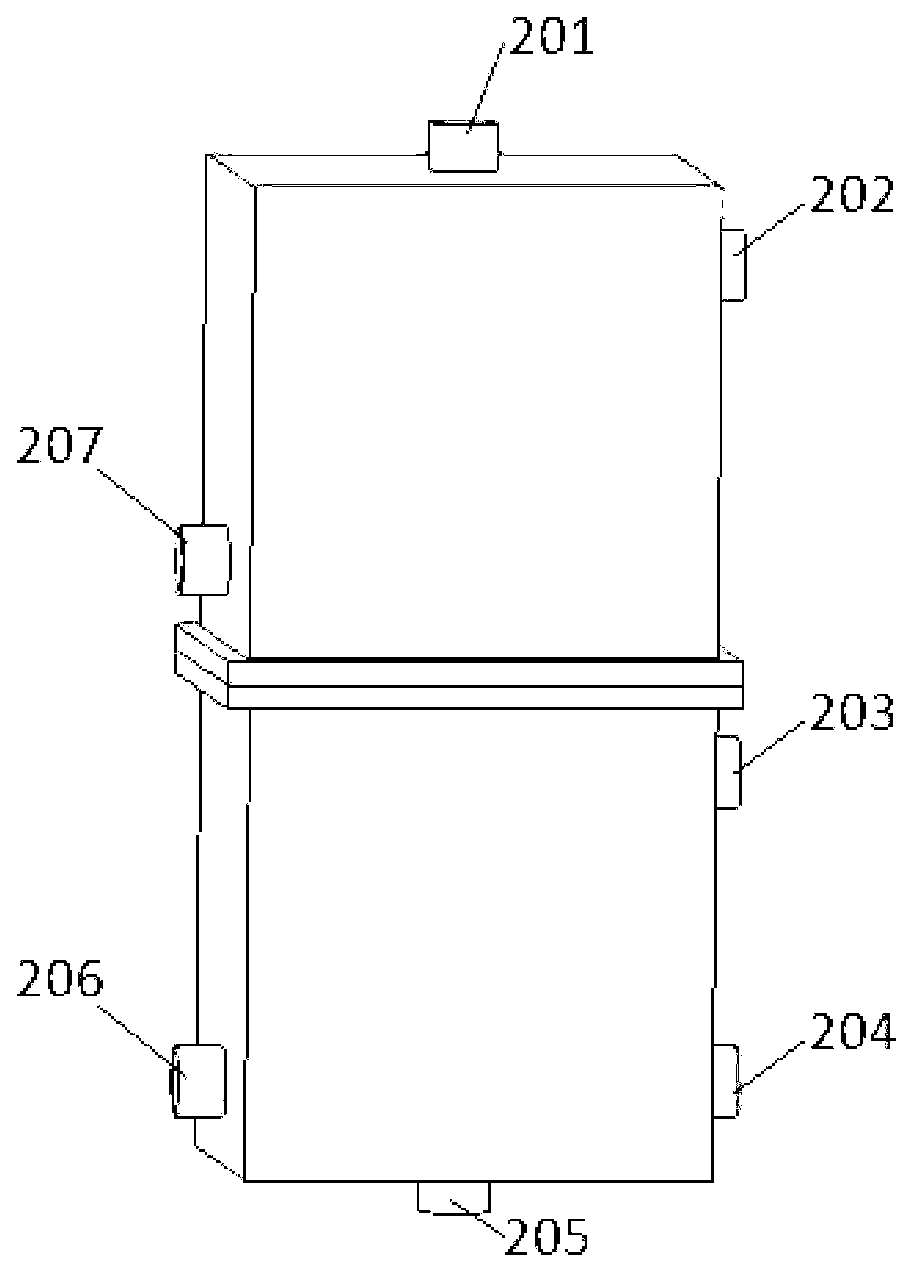

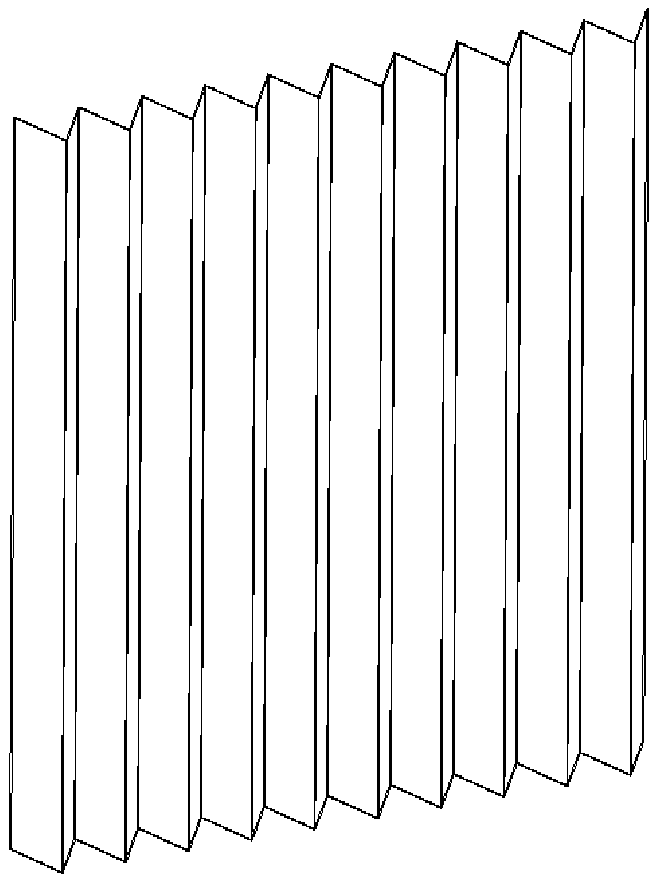

[0018] Refer to attached figure 2 , the organic waste gas recovery device with a new plate structure is divided into two parts, the upper and lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com