Lithium battery diaphragm stretching forming device and method as well as lithium battery diaphragm

A lithium battery separator and stretch forming technology, applied in lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problems of high product shrinkage, necking, and unsatisfactory pore uniformity of lithium battery separators. Achieve the effect of small shrinkage, uniform distribution, and no necking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

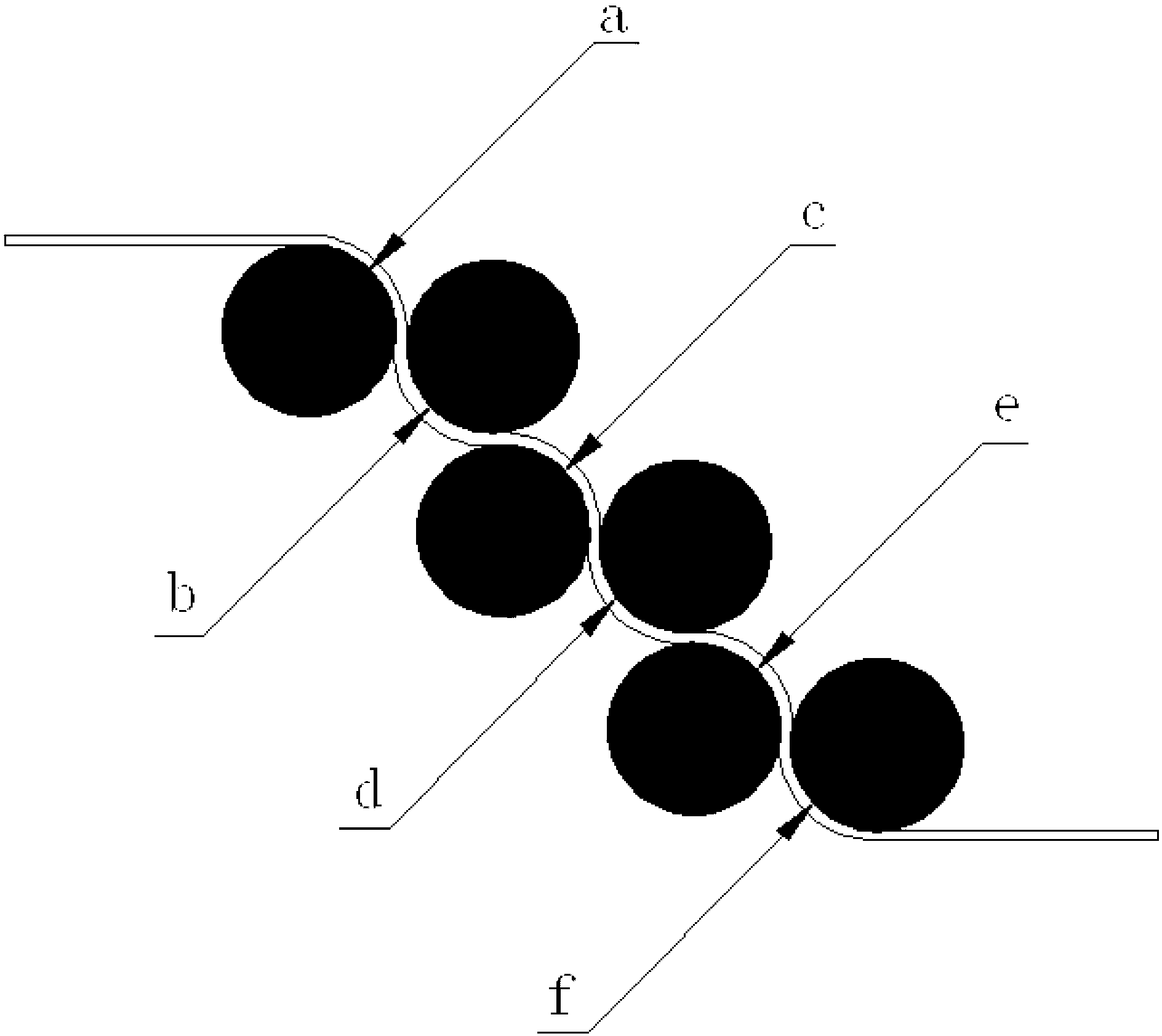

[0025] figure 1 A schematic diagram of a stretching and forming device for a lithium battery separator provided by an embodiment of the present invention is shown, and only parts related to the embodiment of the present invention are shown for convenience of description.

[0026] The lithium battery separator stretching forming device provided in this embodiment includes a plurality of stretching rollers, and the number of stretching rollers is greater than 3, such as figure 1 As shown in the black part, as an implementation, figure 1 It includes six stretching rollers, the white part around the stretching rollers is the film substrate, and the part where the six arrows point to the stretching rollers in the figure is the part where the stretching rollers stretch the film substrate. The force points are points a to f respectively, and the distance between adjacent force points is the stretching gap, as shown in the figure, the distance between points a and b, the distance bet...

Embodiment 2

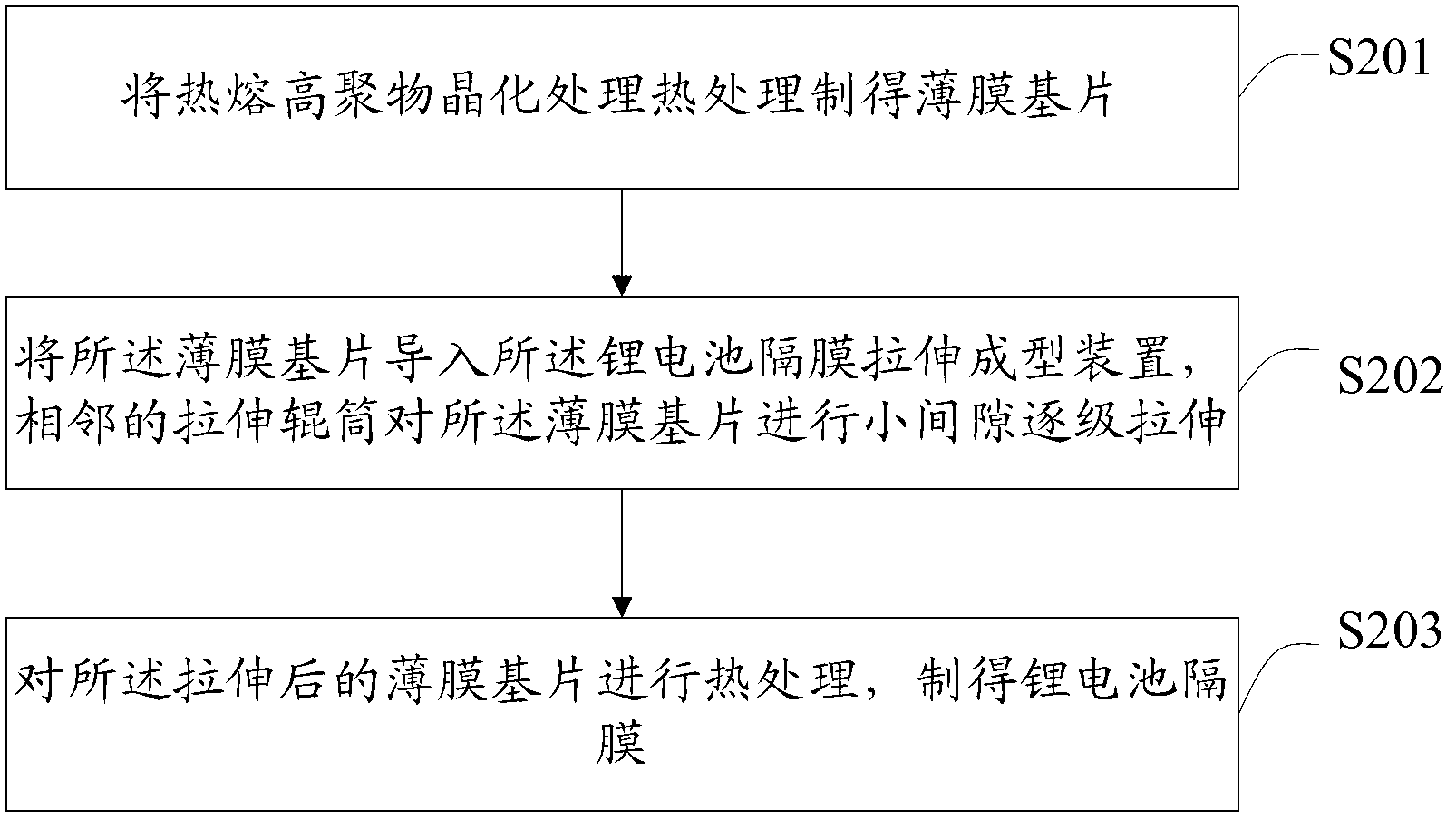

[0030] figure 2 The flow chart of the lithium battery separator stretching forming method provided by the embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0031] The lithium battery diaphragm stretching method provided in this embodiment includes:

[0032] Step S201, crystallize the hot-melt polymer to prepare a film substrate.

[0033] Firstly, the polymer particles are melted and extruded, and then subjected to crystallization treatment to obtain a film substrate. At this time, the film substrate has a wafer structure.

[0034] Step S202 , the film substrate is introduced into the lithium battery separator stretching forming device as described in the above embodiment, and the adjacent stretching rollers stretch the film substrate step by step with small gaps.

[0035] After the film substrate is stretched and formed with small gaps and multi-stages, the wafers a...

Embodiment 3

[0040] The implementation example of the present invention provides a lithium battery diaphragm prepared by the method described in Example 2. After testing, compared with the lithium battery film obtained by the existing large-gap stretching method, the lithium battery diaphragm has a uniform pore size, Uniform distribution, good flatness of the diaphragm, small shrinkage rate, and no necking phenomenon. Ultimately, the lithium battery manufactured by using the lithium battery thin film provided in this embodiment has better overall performance and longer service life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com