Low softening point emulsified bitumen for drilling fluid and preparation method thereof

A low softening point, emulsified asphalt technology, applied in chemical instruments and methods, drilling compositions, building components, etc., can solve problems such as hole wall instability, improve hole wall stability, save resources, and prepare methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

[0032] Add solvent oil and nonionic surfactant into the oil slurry, heat and stir evenly to obtain the oil slurry mixture; then add water, C 2 ~C 4 Add alcohol and cationic surfactant into the reactor, heat and stir until the cationic surfactant is fully dissolved, then add the oil slurry mixture into the reactor, at a temperature of 45~90°C and a stirring rate of 200~1000rpm, Stir and react for 30-60 minutes to obtain low softening point emulsified asphalt.

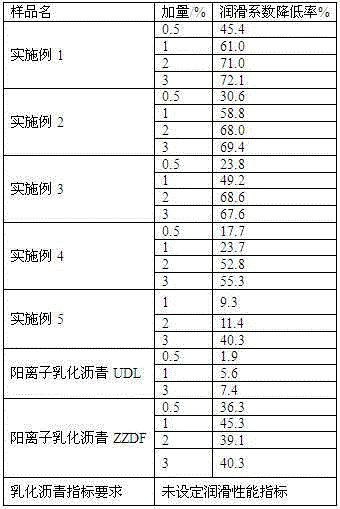

[0033] Table 1 Preparation of emulsified asphalt with different component additions and reaction conditions

[0034] raw material Example 1 Example 2 Example 3 Example 4 Example 5 oil slurry 25 copies 35 copies 30 copies 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| colloidal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com