Low-grade non-oriented silicon steel produced in continuous casting and rolling processes of sheet billet and preparation method thereof

A thin slab continuous casting, oriented silicon steel technology, applied in metal rolling and other directions, can solve the problems of large rolling mill load, increased burden, difficult plate shape control, etc., to achieve good magnetic properties, reduce production costs, and reduce production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

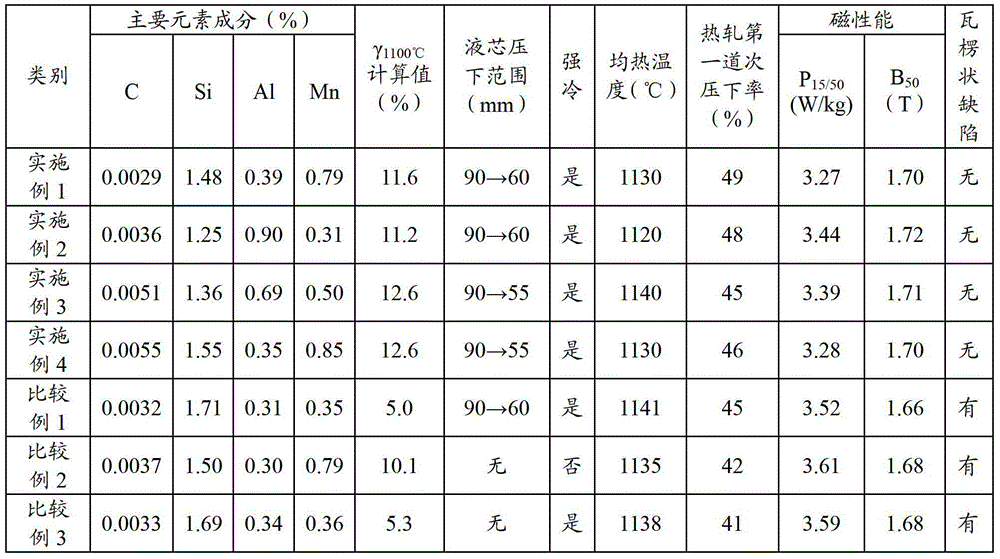

[0034] Prepare raw materials according to the following chemical composition in mass percentage: C: 0.0029%, Si: 1.48%, Al: 0.39%, Mn: 0.79%, P: 0.021%, N: 0.0035%, S: 0.0039%, the rest is iron and To avoid impurities, carry out smelting and vacuum refining.

[0035] Afterwards, thin slab continuous casting is carried out, and the liquid core reduction process is adopted to reduce the thickness of the slab from 90mm at the exit of the crystallizer to 60mm. %, the average grain size of the equiaxed grains is about 1.62mm, and the distance between the primary dendrite arms of the columnar grains in the slab is about 380μm; after soaking at 1130°C, it is hot-rolled, and the first-pass rolling reduction rate is 49% ; After pickling, the hot-rolled sheet is cold-rolled to a thickness of 0.5 mm, and then annealed and coated in a continuous annealing and coating unit.

[0036] Finished iron loss P 15 / 50 3.27W / kg, magnetic induction B 50 It is 1.70T, and there are no corrugated def...

Embodiment 2

[0038] Raw materials are prepared according to the chemical composition of the following mass percentages: C: 0.0036%, Si: 1.25%, Al: 0.90%, Mn: 0.31%, P: 0.07%, N: 0.0038%, S: 0.0038%, and the rest is iron and To avoid impurities, carry out smelting and vacuum refining.

[0039] Afterwards, thin slab continuous casting is carried out, and the liquid core reduction process is adopted to reduce the thickness of the slab from 90mm at the exit of the crystallizer to 60mm. %, the average grain size of equiaxed grains is about 1.50mm, and the primary dendrite arm spacing of columnar grains in the slab is about 340μm; after soaking at 1120°C, hot rolling is performed, and the reduction rate of the first rolling pass is 48% ; After pickling, the hot-rolled sheet is cold-rolled to a thickness of 0.5 mm, and then annealed and coated in a continuous annealing and coating unit.

[0040] Finished iron loss P 15 / 50 3.44W / kg, magnetic induction B 50 It is 1.72T, and there are no corrugat...

Embodiment 3

[0042]Raw materials are prepared according to the chemical composition of the following mass percentages: C: 0.0051%, Si: 1.36%, Al: 0.69%, Mn: 0.50%, P: 0.03%, N: 0.0036%, S: 0.0040%, and the rest is iron and To avoid impurities, carry out smelting and vacuum refining.

[0043] Afterwards, thin slab continuous casting is carried out, and the liquid core reduction process is adopted to reduce the thickness of the slab from 90mm at the exit of the crystallizer to 55mm. %, the average grain size of equiaxed grains is about 1.47mm, and the primary dendrite arm spacing of columnar grains in the slab is about 355μm; after soaking at 1140°C, hot rolling is carried out, and the rolling reduction rate of the first pass is 45% ; After pickling, the hot-rolled sheet is cold-rolled to a thickness of 0.5 mm, and then annealed and coated in a continuous annealing and coating unit.

[0044] Finished iron loss P 15 / 50 3.39W / kg, magnetic induction B 50 It is 1.71T, and there are no corruga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com