Vertical worm and worm gear mechanism with self-lubricating function

A technology of worm gear and worm gear, which is applied in the direction of gear lubrication/cooling, mechanical equipment, belt/chain/gear, etc. It can solve the problems of increasing the production and application cost of the reducer, not easy to process deep holes, and large oil churning loss, etc., to achieve improved Transmission efficiency, installation flexibility, simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

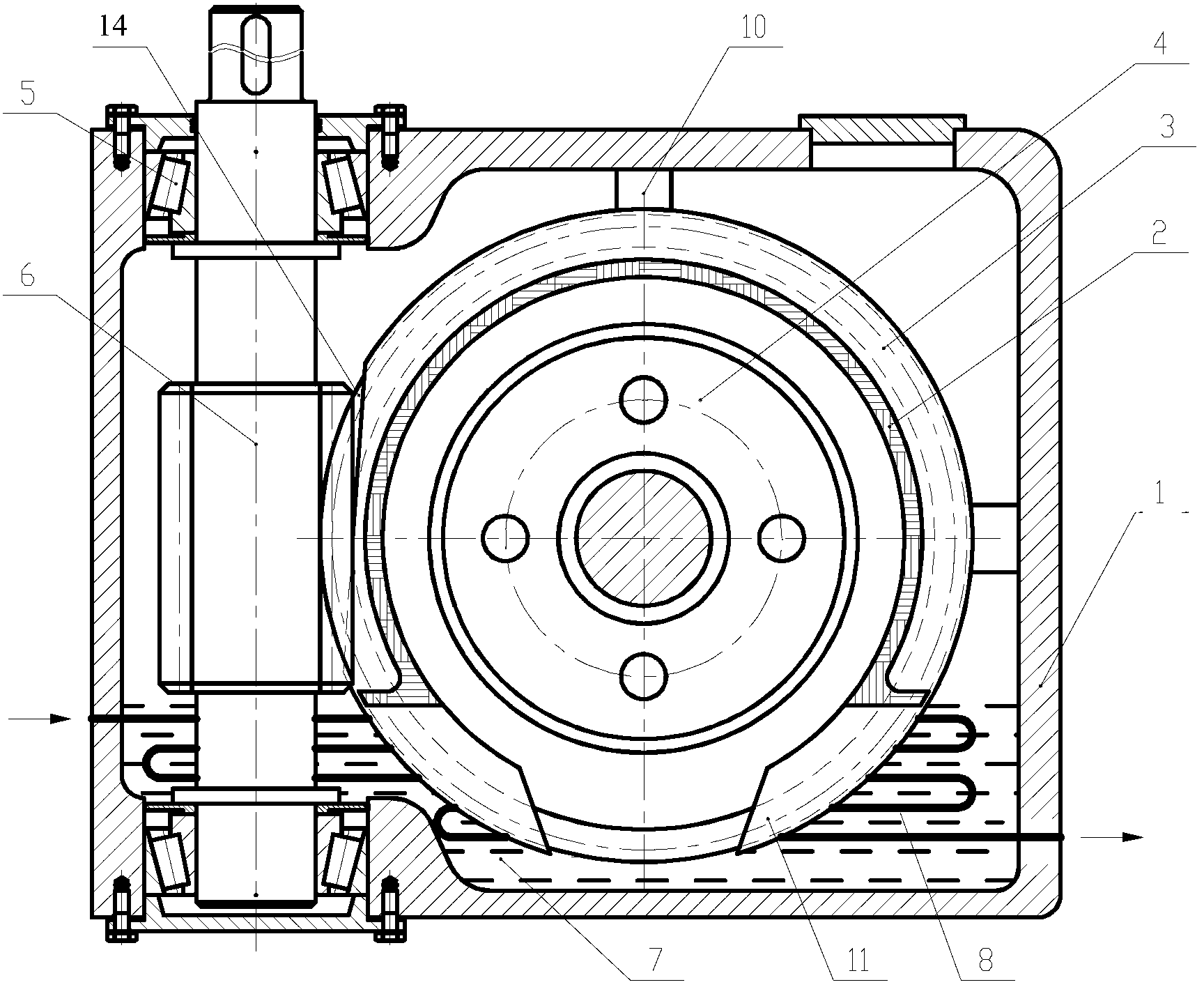

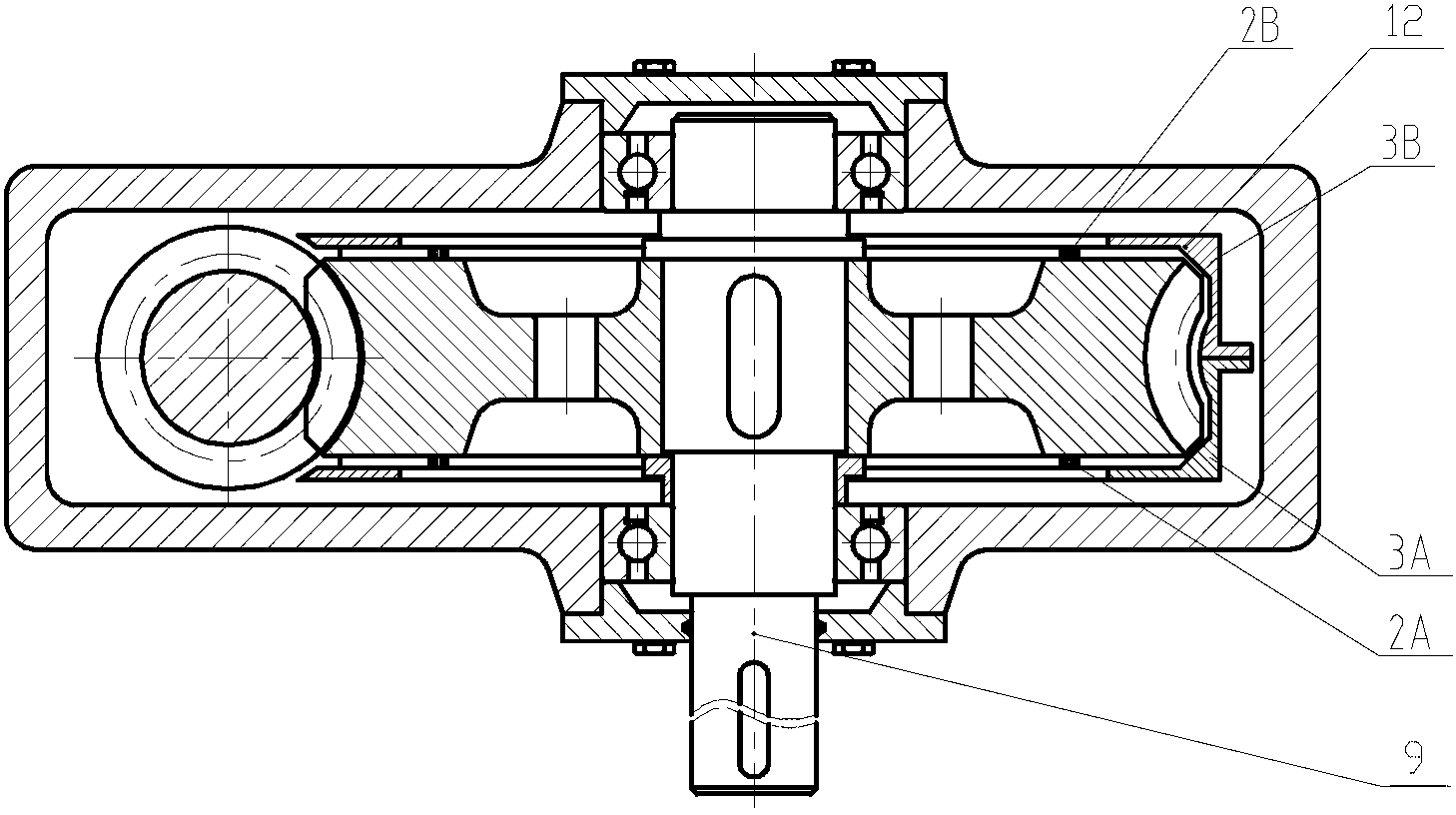

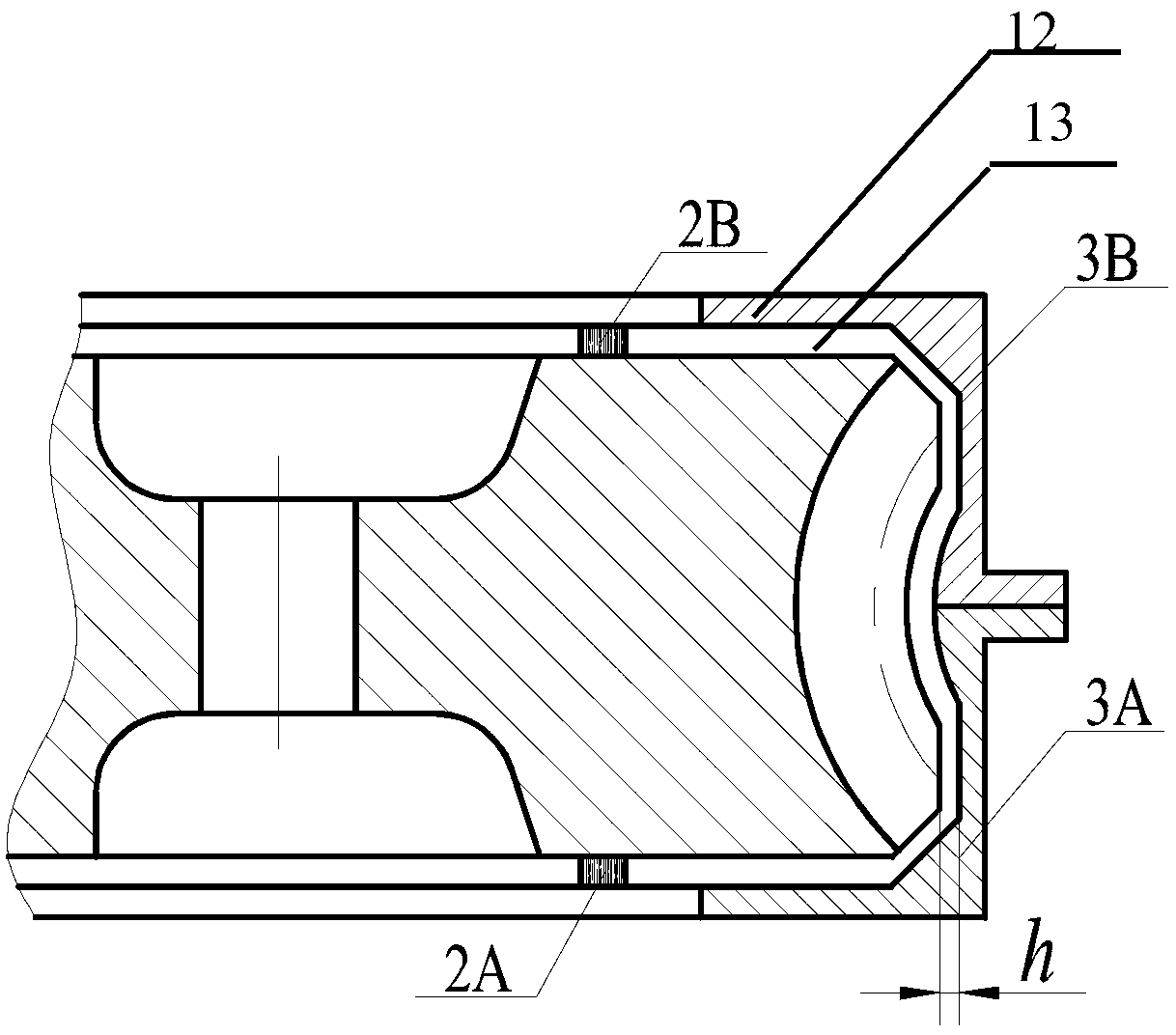

[0012] see figure 1 and figure 2 As shown, the present invention discloses a vertical worm gear mechanism with self-lubricating function, which includes a box body 1, a worm wheel 4 and a worm screw 6 installed in the box body 1 and intermeshing with each other, and the worm screw 6 is vertically arranged in the box body In body 1. An oil scraper cover 3 covering the outer edge of the worm wheel 4 is also provided, and the oil scraper cover 3 includes an inlet 11 at the bottom, side walls 12 covering both sides of the outer edge of the worm wheel 4; the two side walls 12 A seal 2 is interposed between the worm wheel 6, and an oil inlet channel 13 is formed between the side wall 12, the seal 2 and the worm wheel 6, and one side of the oil inlet channel 13 communicates with the inlet 11 and the other The side communicates with the meshing part of the worm gear. The two end faces of the worm gear 4 matched with the oil scraper cover 3 are installed with seals 2A, 2B, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com