Measuring tool for measuring dimensional tolerance between carrying surface and reference surface of fir-type race of steam turbine rotor and measuring method of measuring tool

A steam turbine rotor and dimensional tolerance technology, which is applied in the field of steam turbine processing, can solve the problems that general measuring tools cannot be measured, and achieve the effect of ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

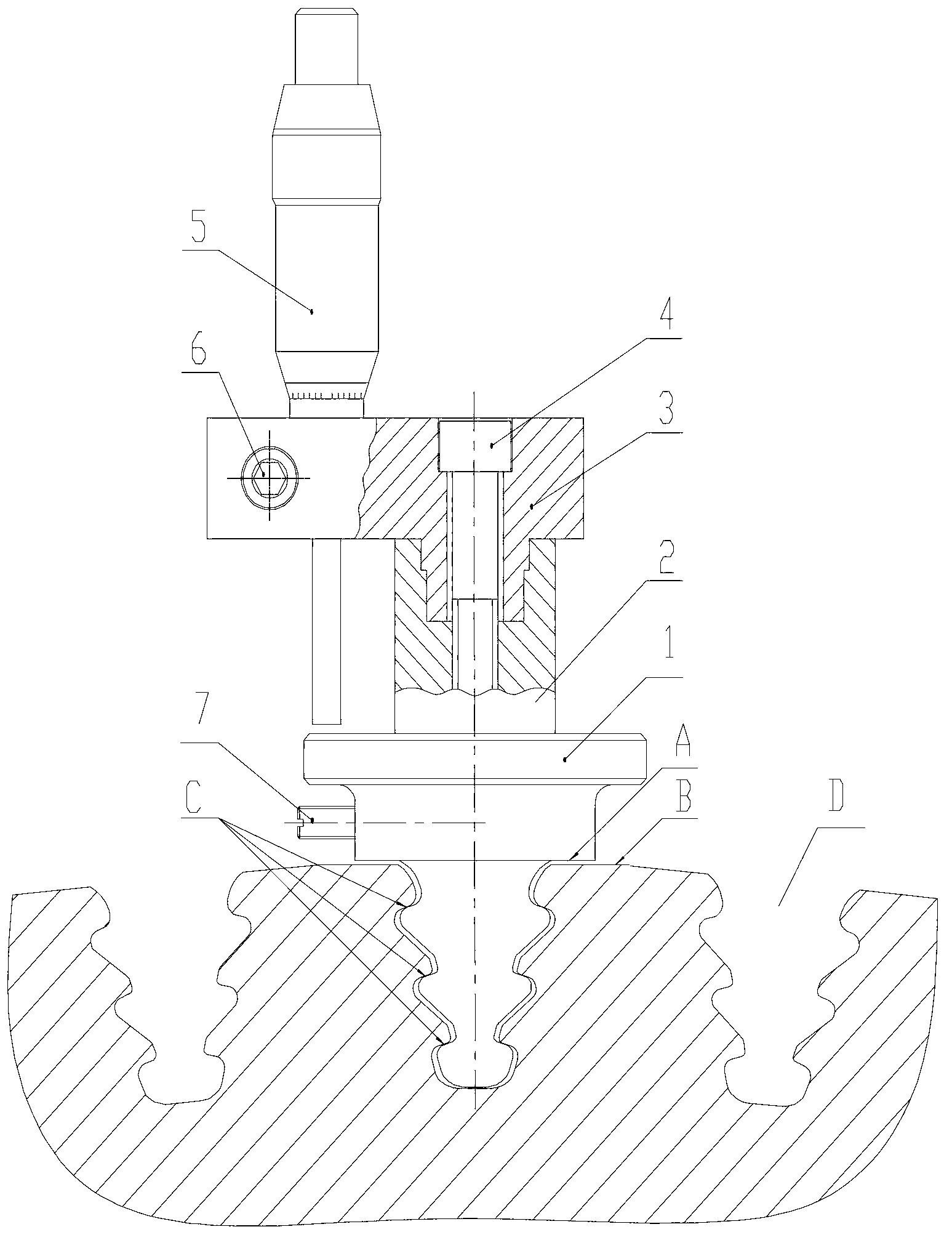

[0019] Specific implementation mode 1. Combination figure 1 This specific embodiment will be described. A steam turbine rotor fir-tree-shaped wheel groove bearing surface to the reference plane dimensional tolerance measuring tool, the measuring tool includes an adjusting nut 1, a sample column 2, a clamping positioning part 3, a hexagon socket head screw 4, a micrometer head 5, screw 6 and set screw 7;

[0020] The adjusting nut 1 is set on the sample column 2, and the two are threaded, and the position of the adjusting nut 1 and the sample column 2 is fixed by the set screw 7;

[0021] The clamping positioning part 3 is installed on the top of the sample column 2, the lower end surface of the clamping positioning part 3 is closely connected with the upper end surface of the sample column 2, and the two are fixedly connected by a hexagon socket head cap screw 4,

[0022] There is a micrometer screw hole on the clamping locator 3, the micrometer head 5 is installed on the cl...

specific Embodiment approach 2

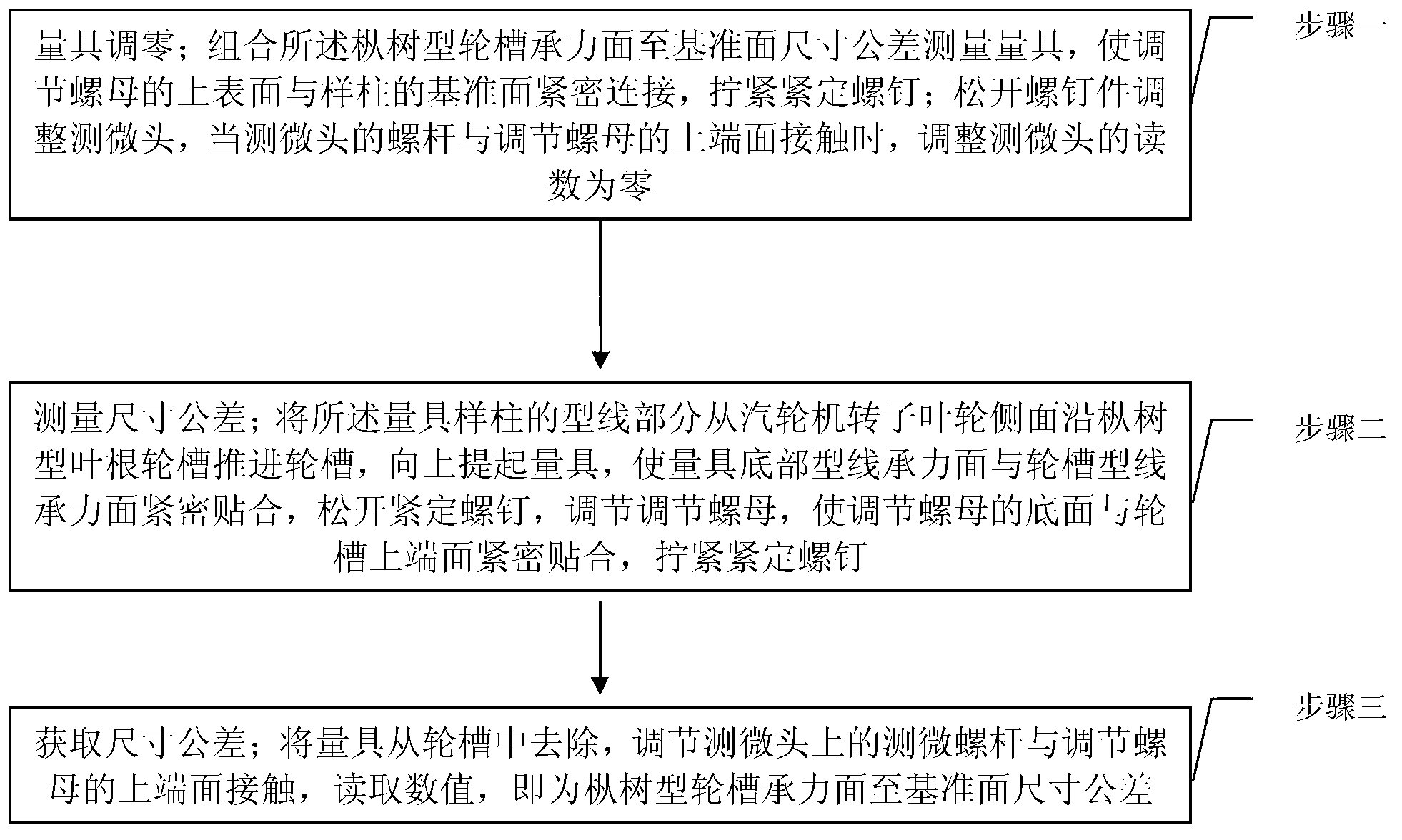

[0023] Specific embodiment two, combine figure 2 This specific embodiment will be described. Based on the measurement method of a steam turbine rotor fir-tree-shaped wheel groove bearing surface to the reference surface dimensional tolerance measuring device described in the first specific embodiment, the method includes the following steps:

[0024] Step 1: Zeroing the gauge;

[0025] The process of zeroing the measuring tool is to combine the bearing surface of the fir tree-shaped wheel groove to the measuring tool for the size tolerance of the reference surface, so that the upper surface of the adjusting nut 1 is closely connected with the reference surface of the sample column 2, and the set screw 7 is tightened; Loosen screw 6 to adjust micrometer head 5, when the screw rod of micrometer head 5 is in contact with the upper end surface of adjustment nut 1, adjust the reading of micrometer head 5 to be zero;

[0026] Step 2: Measure the dimensional tolerance;

[0027] T...

specific Embodiment approach 3

[0030] Embodiment 3. This embodiment is different from Embodiment 2 in that the dimensional tolerance from the bearing surface of the fir tree-shaped wheel groove to the reference plane in step 3 is -0.1 to 0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com