Measuring refractive index device and method thereof

A measuring device and technology of refractive index, which is applied in the field of optical detection, can solve the problems of long period, prism manufacturing trouble, refractive index difference, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

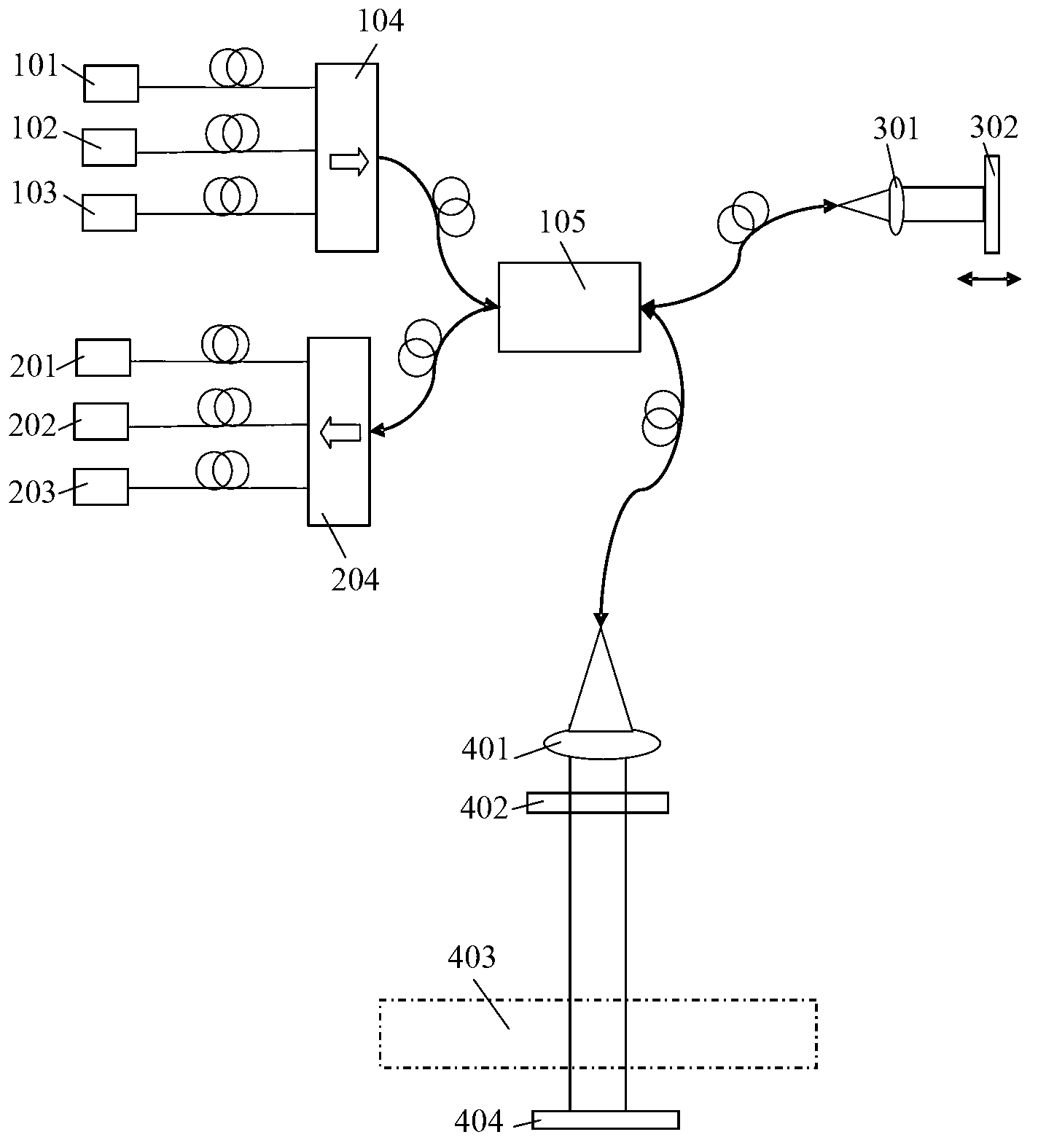

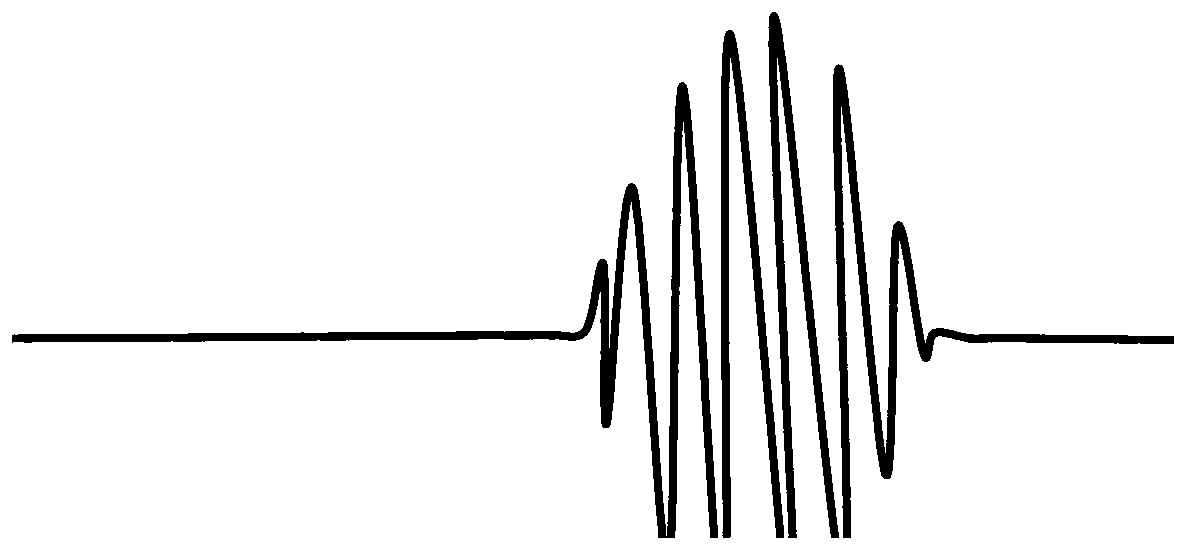

[0051] Usually the refractive index data of glass contains three refractive index wavelengths to determine the refractive index and dispersion coefficient of the material, such as figure 2 As shown, short coherent light sources 101 (red LED), 102 (green LED), and 103 (blue LED) of three wavelengths are input into the optical fiber, coupled into an optical fiber through a wavelength division multiplexer 104, and passed through The fiber coupler 105 (that is, 2×2 fiber coupler), the light output from the fiber coupler is collimated by the first fiber collimator 301, and is incident on a precision movable mirror 302, and passes through the mirror 302 The reflected light passes through the fiber collimator 301 again, is coupled to the fiber and then enters the fiber coupler 105. This light is the reference light;

[0052] The other light output from the fiber coupler 105 is collimated by the second fiber collimator 401, then exits to a transparent plate 402, then passes through t...

Embodiment 2

[0059] In a manner similar to Embodiment 1, when testing a transparent liquid state, the liquid state is placed in a vessel containing the liquid state, and the bottom of the vessel has a plane, similar to the reflector 404 in the previous embodiment 1, and the height of the liquid state can be Through the test on the upper surface of the transparent plate 402 and the liquid, the distance between the transparent plate 402 and the reflector 404 measured when the liquid is added or not added will change, and the liquid can be obtained by the change value and the height of the liquid the refractive index value. Since the distance b between the lower surface of the liquid and the bottom surface of the container is 0; so the refractive index n=(L2-L1) / (L1-a), where L2 is the original distance between the transparent plate 402 and the reflector 404, and L1 is transparent The distance between the flat plate 402 and the reflecting mirror 404 after adding the measuring liquid, a is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com