Piezoelectric plate and vibration energy collector

A vibration energy harvesting, piezoelectric sheet technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc. Potential generation, piezoelectric effect is not very effective, etc., to achieve effective performance, improve energy output efficiency, reduce the effect of resonance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

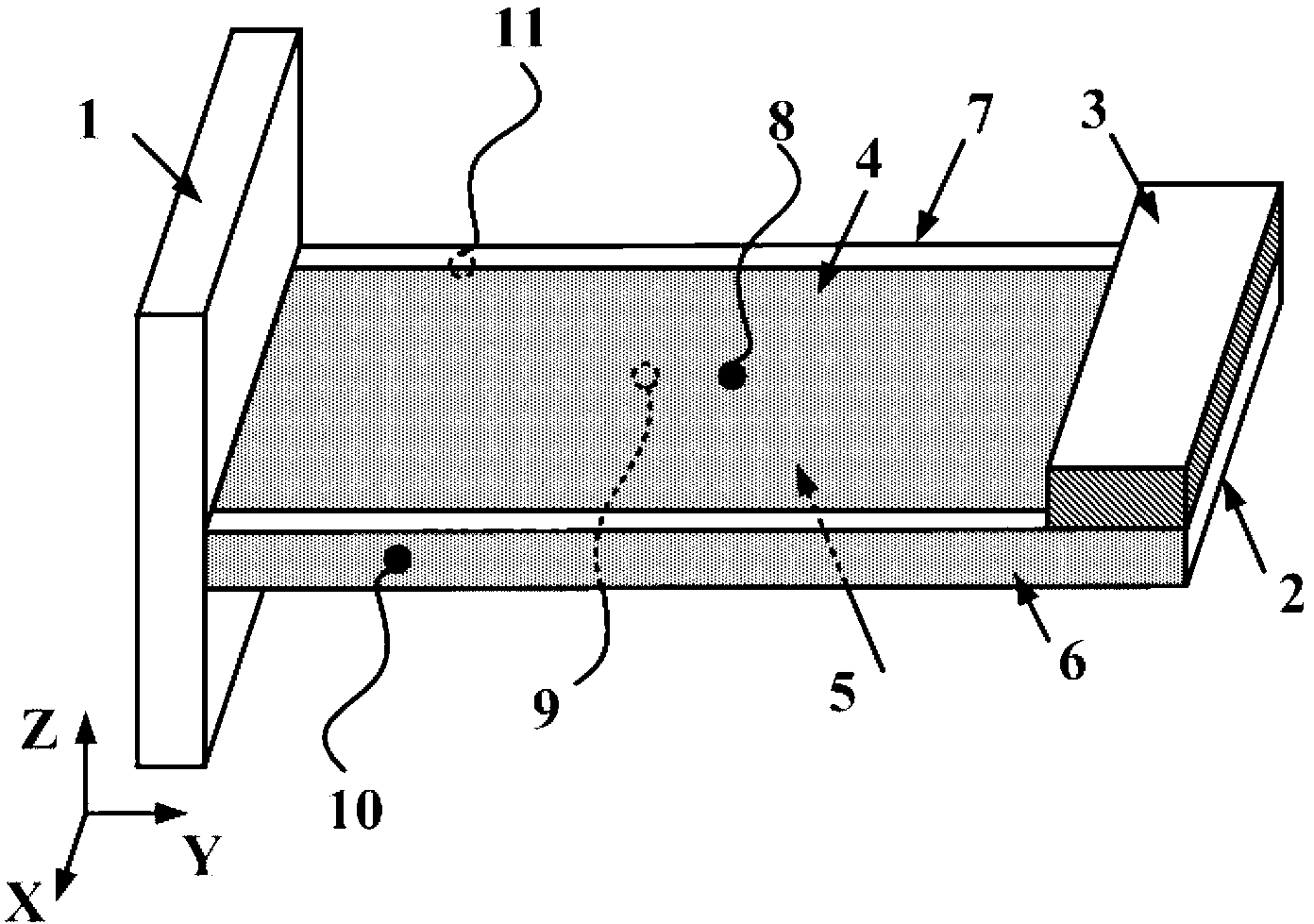

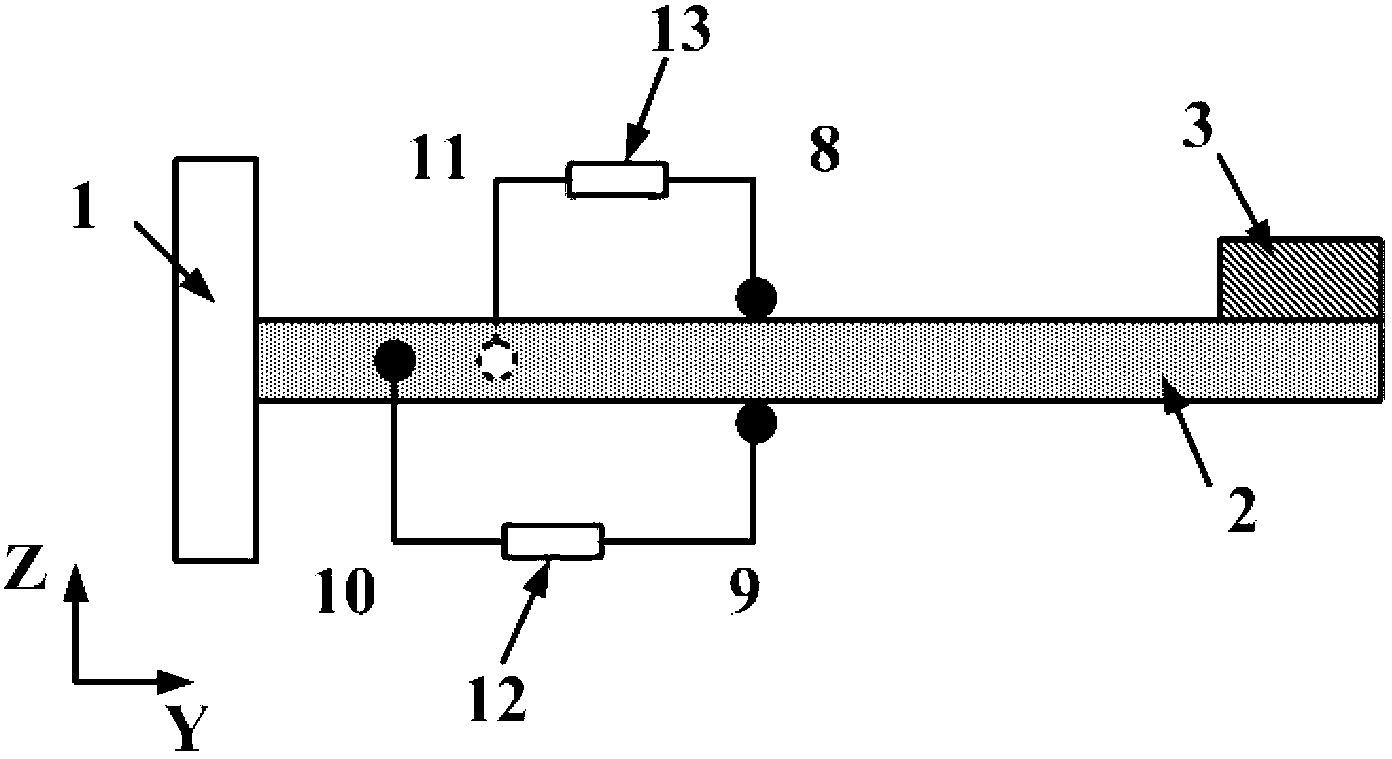

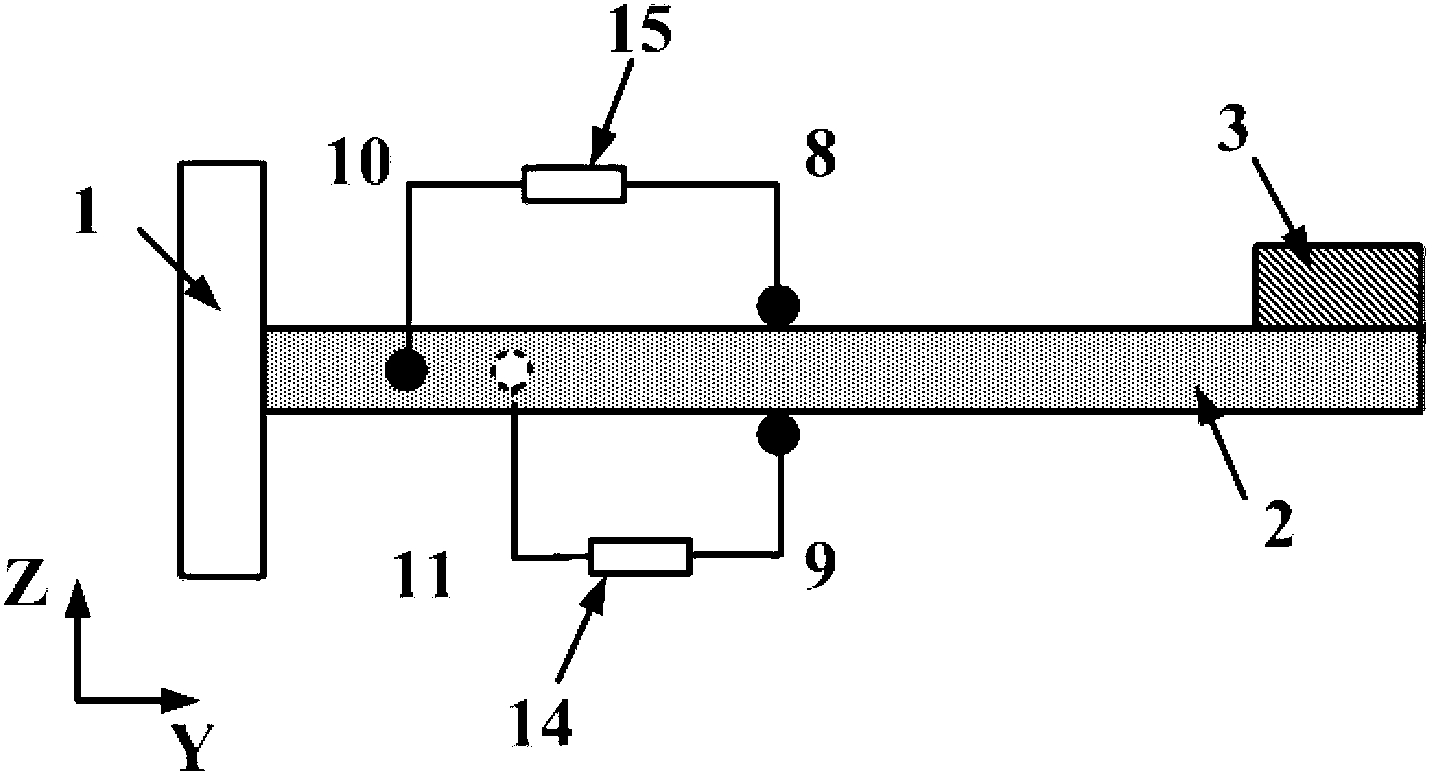

[0027] see figure 1 , a vibration energy harvester, including a single-layer piezoelectric sheet, one end of the piezoelectric sheet is fixed on the base 1 to form a cantilever beam structure, so that the piezoelectric sheet can vibrate with the vibration of the external environment, and the other end is Free end, the upper surface of the free end of the piezoelectric sheet is fixed with a mass block 3 made of copper, molybdenum or tungsten, which can make the piezoelectric sheet produce a certain pre-strain, and adjust the resonance of the piezoelectric sheet by changing the quality of the mass block 3 frequency; the piezoelectric sheet includes a piezoelectric sheet body 2, the upper and lower surfaces of the piezoelectric sheet body 2 are respectively coated with an upper surface electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com