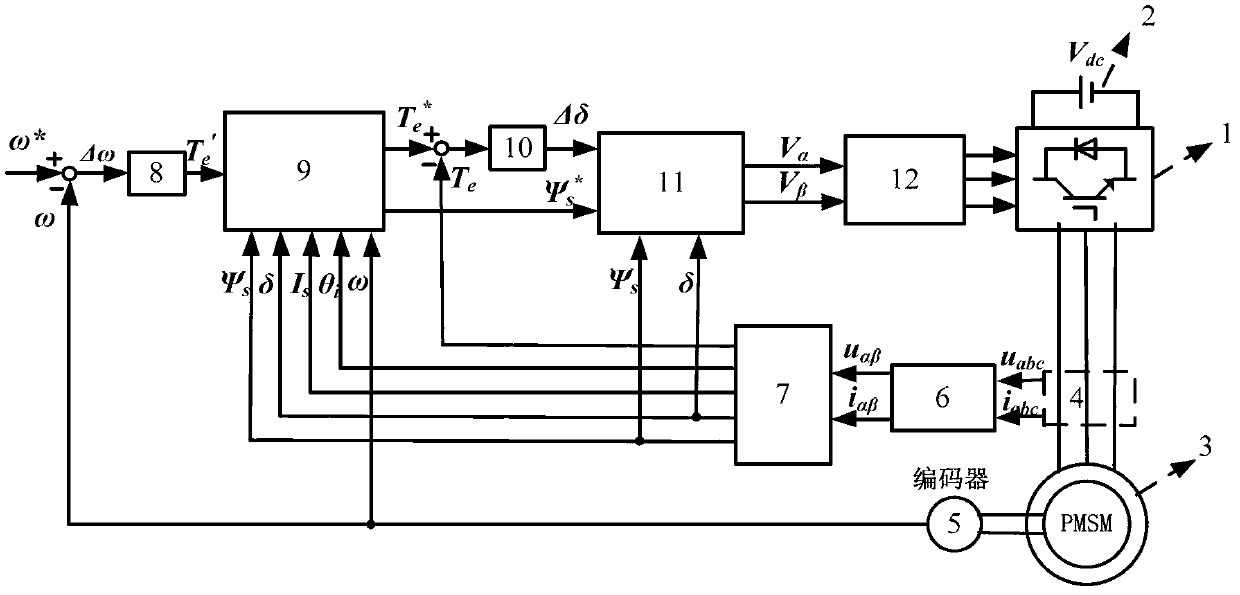

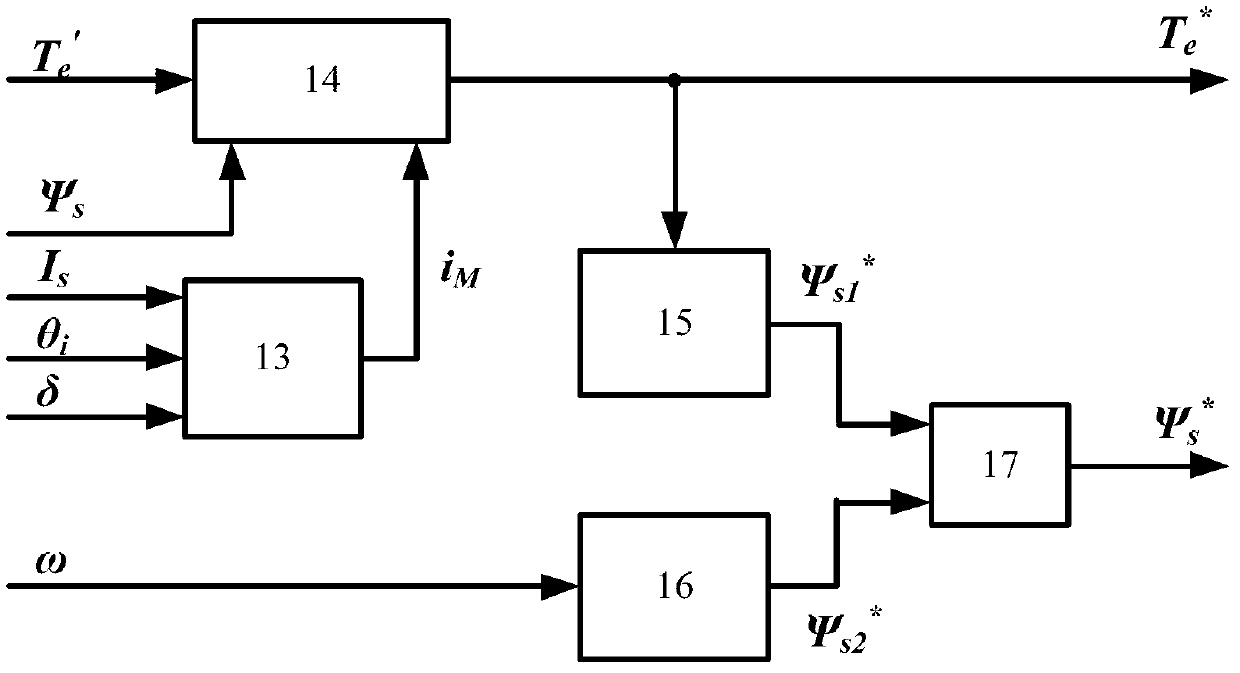

Method for controlling direct torsion/ flux linkage of permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and control method, which is applied in the direction of single motor speed/torque control, motor generator control, electronic commutation motor control, etc., and can solve the problems of complex calculation and dynamic performance without direct torque control, etc. Achieve the effect of simple calculation, fast dynamic response and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

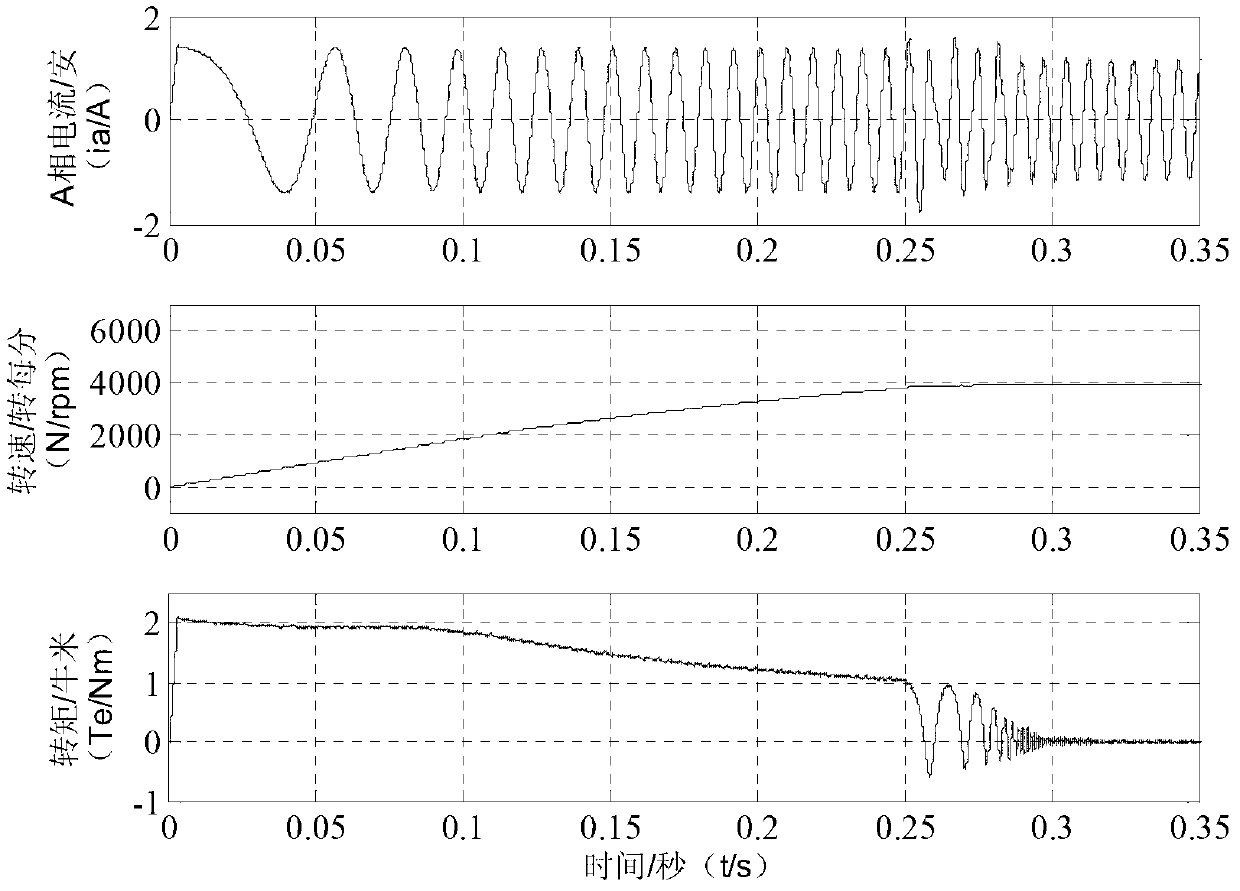

[0061] Below, we conduct a simulation test on this embodiment, and the parameters of the permanent magnet synchronous motor used are shown in Table 1:

[0062] Table 1

[0063] Number of pole pairs

2

Stator resistance

18.6Ω

Permanent magnetic flux linkage

0.447Wb

Direct axis inductance

0.3885H

Quadrature axis inductance

0.4755H

phase voltage

240V

phase current

1.4A

Rated speed

1500rpm

Rated torque

1.94Nm

[0064] The goal of the test is to make the motor run stably at 6000 rpm.

[0065] image 3 It is the current, speed and torque waveform diagram of the direct torque control of the traditional permanent magnet synchronous motor. It can be seen that the output torque of the motor drops severely at time t=0.25s, the current is unstable, the system loses balance, and the speed of the motor no longer rises.

[0066] Figure 4 It is the current, rotational speed and to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com