Macromolecule composite electric heating material, preparation method thereof and application thereof

A technology of electrothermal materials and polymers, applied in the field of polymer composite electrothermal materials, can solve the problems of weak adjustability of electrothermal performance, non-100% effective heating area, narrow adjustable range of conductive ink printing volume, etc., and achieve high electrothermal conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1) The formula of the polymer composite electric heating coating is as follows in parts by weight:

[0051] Polyurethane resin (NIPPOLAN2301, Nippon Polyurethane Industry Co., Ltd.) 100 parts, acetylene carbon black 5.3 parts, magnesium oxide (purity ≥ 95%) 3.5 parts, zinc oxide (purity ≥ 95%) 3.5 parts, phthalate 9 parts of octyl ester, 1.8 parts of stearic acid, 0.8 parts of dispersant (Tween20), 270 parts of solvent (ethyl acetate, purity ≥ 95%).

[0052] 2) The preparation method of polymer composite electrothermal coating is as follows:

[0053] a) Accurately weigh conductive filler (acetylene carbon black), other additives (magnesium oxide, zinc oxide), dispersant (Tween20), plasticizer (dioctyl phthalate) and lubricant (stearic acid) placed in a container;

[0054] b) Weigh about two-thirds of the solvent (ethyl acetate) and add it to the above container;

[0055] c) After the above materials are fully infiltrated, accurately weigh and add polymer resin base m...

Embodiment 2 to Embodiment 5

[0070] The formula of embodiment 2 to embodiment 5 is similar to embodiment 1, and difference is: the compounding quantity of acetylene carbon black is 6 parts among the embodiment 2; In embodiment 3, acetylene carbon black is 6 parts, and conductive graphite is 6 parts Part; In embodiment 4, acetylene carbon black is 6 parts, and conductive graphite is 10.5 parts; In embodiment 5, acetylene carbon black is 8 parts.

[0071] The preparation method of the polymer composite electrothermal coating, the production method of the polymer composite electrothermal material and the test method of the resistance value of the sample are the same as in Example 1.

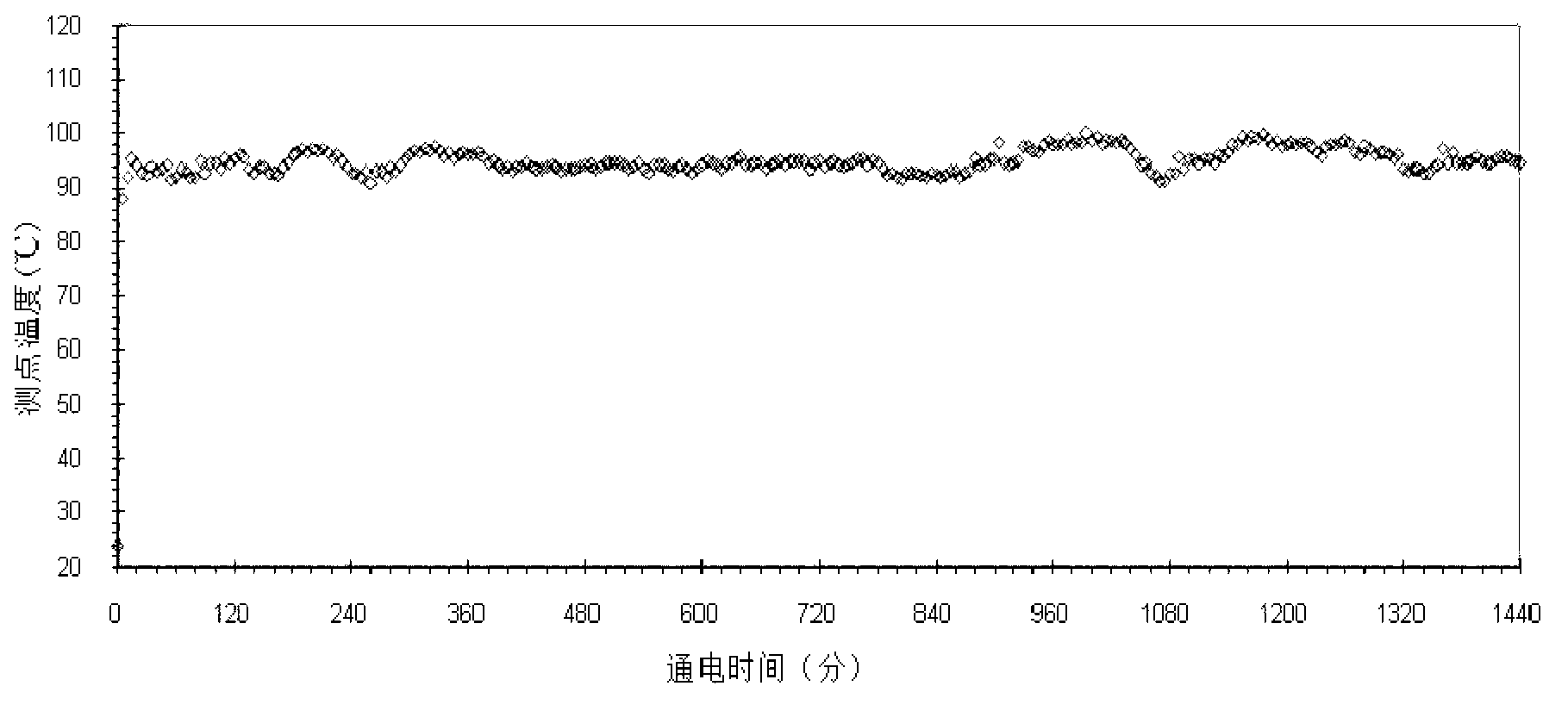

[0072] Test Results:

Embodiment 2

[0073] Example 2, resistance R=10.8kΩ; Example 3, resistance R=4310Ω; Example 4, resistance R=3660Ω; Example 5, resistance R=3560Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com