Air damper for vehicle

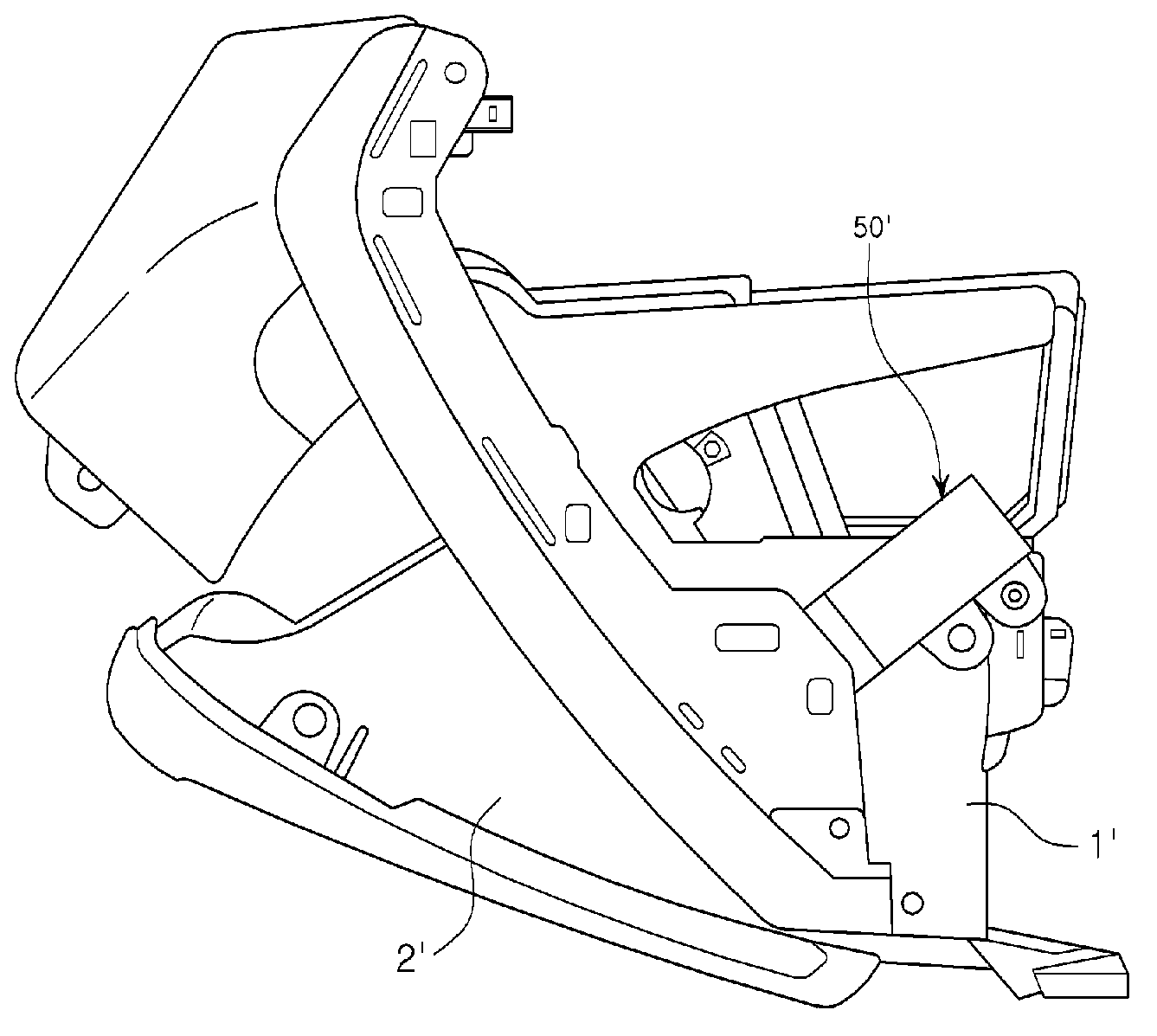

An air damping, automotive technology, applied in the direction of shock absorbers, shock absorbers, passenger space, etc., can solve the problems of increased defect rate, decreased productivity, increased air damper process and time, etc., to reduce the number of parts, prevent The effect of incorrect assembly and increased product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

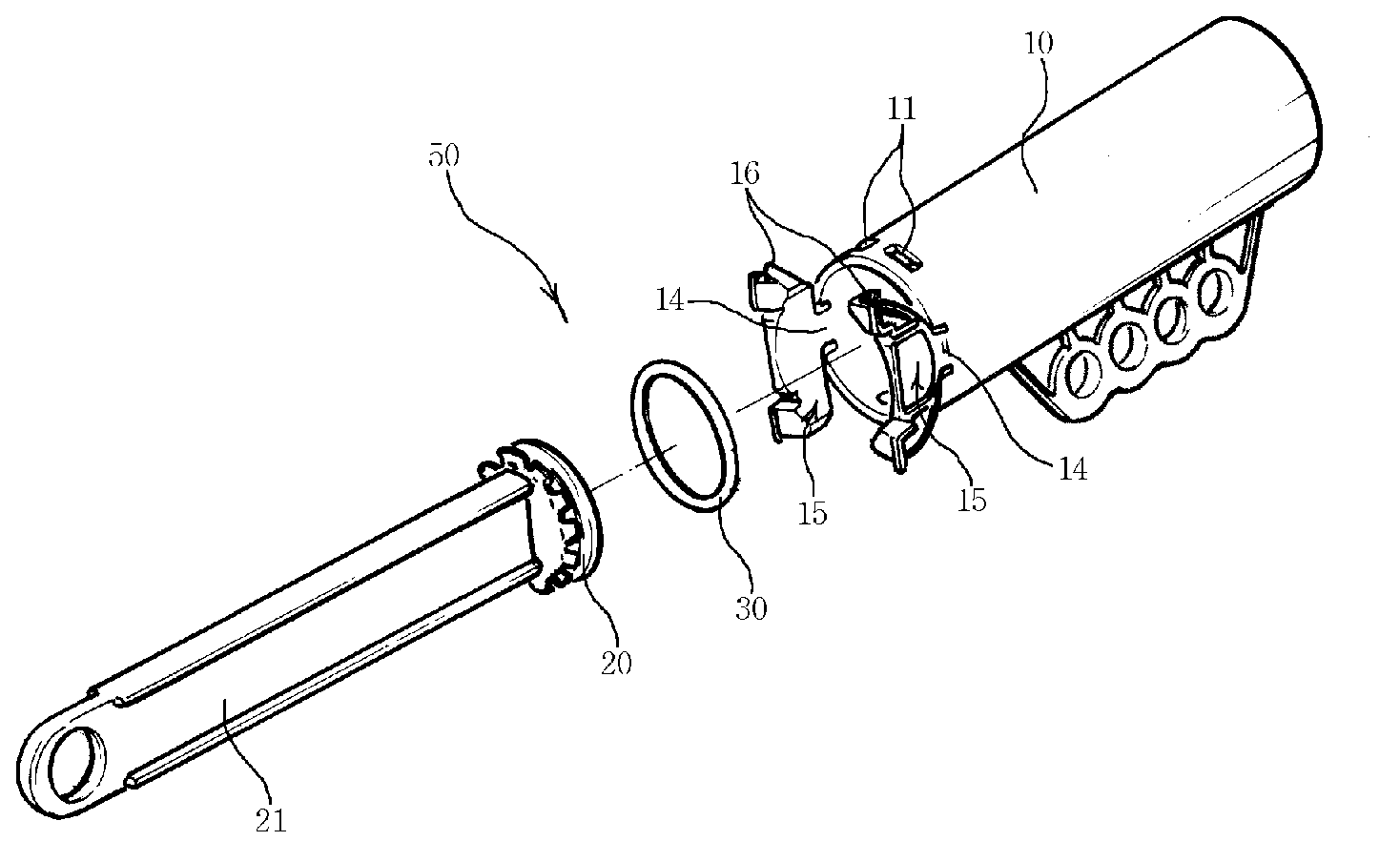

[0024] Hereinafter, configuration and operation examples of the present invention for achieving the above objects will be described with reference to the drawings.

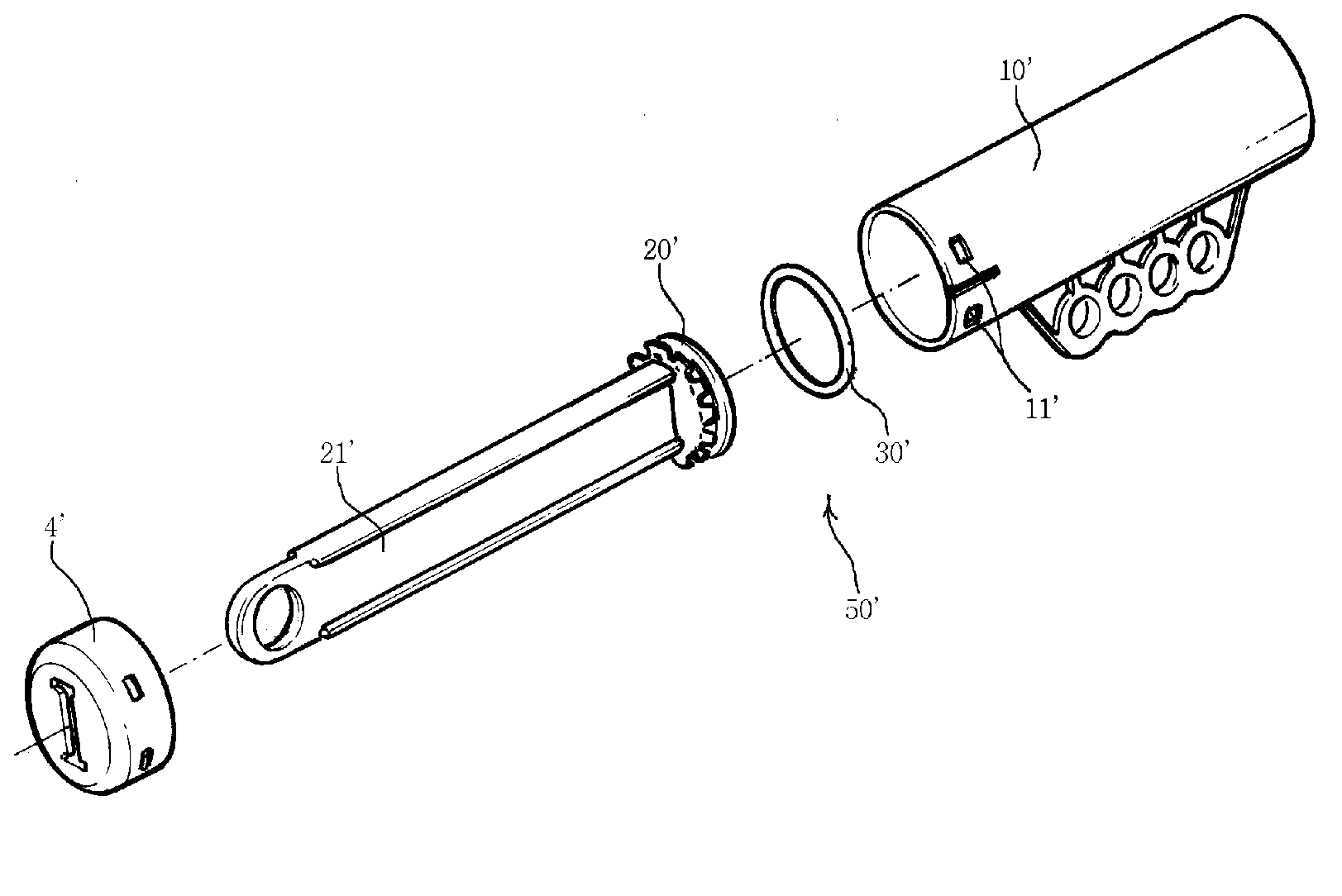

[0025] In the air damper for automobiles according to the present invention, the opening of the housing is integrally injection-molded with covers divided on both sides, and after assembling the piston, the covers are joined together to cover the opening and support the piston rod, thereby enabling Reduces parts count and shortens assembly and operating time.

[0026] First, with Figure 3a and Figure 3b As a reference, the general direction reference used in this specification will be described. The piston 20 is inserted into the inside of the housing 10 to define an air chamber. Simultaneously, the piston rod 21 closes the opening.

[0027] At this time, an O-ring 30 is provided on the piston 20. The O-ring 30 is sleeved on the outer peripheral edge of the piston 20, and moves in contact with the inner diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com