Variable seeding control system and method based on pressure sensor

A technology of pressure sensor and control system, which is applied to the parts of planters, etc., and can solve the problems of low displacement detection accuracy and inaccurate displacement control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] This example adopts the eccentric wheel hole type seed meter.

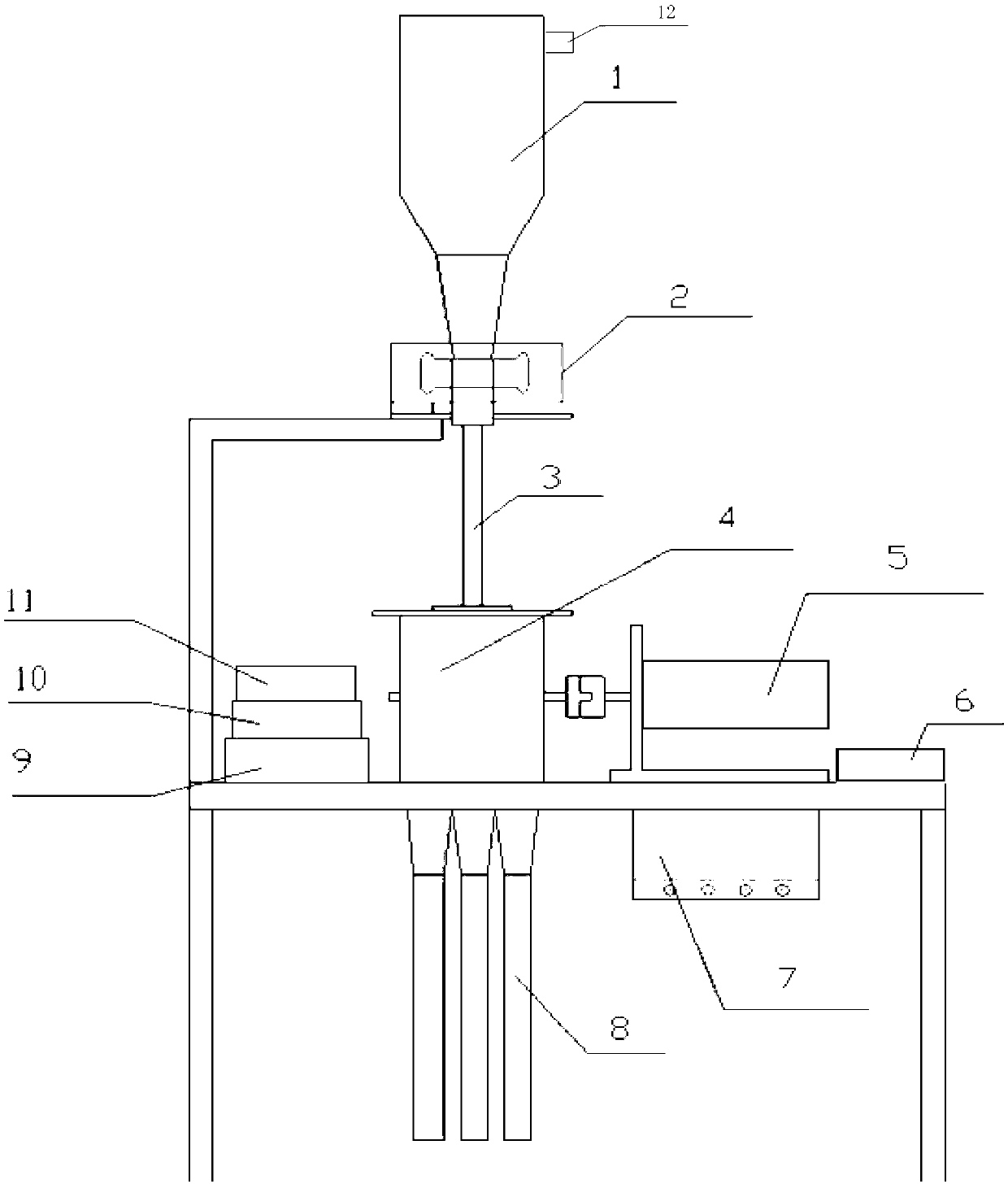

[0032] Such as figure 1 Shown is a structural block diagram of a pressure sensor-based variable seeding control system of the present invention, including a pressure sensor 2, an acceleration sensor 12, a processor unit 11, a digital-to-analog conversion unit 10, a voltage amplifier 9, a motor 5, and a motor driver 6 and human-computer interaction unit 7;

[0033] Wherein, the pressure sensor is arranged at the lower port of the seed box 1 of the seed meter, the acceleration sensor 12 is arranged at the frame, the motor 5 is connected with the seed unit 4, and the pressure sensor, voltage amplifier, digital-to-analog conversion unit, processing The controller unit, the motor drive unit and the motor are connected in sequence, and the human-computer interaction unit is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com