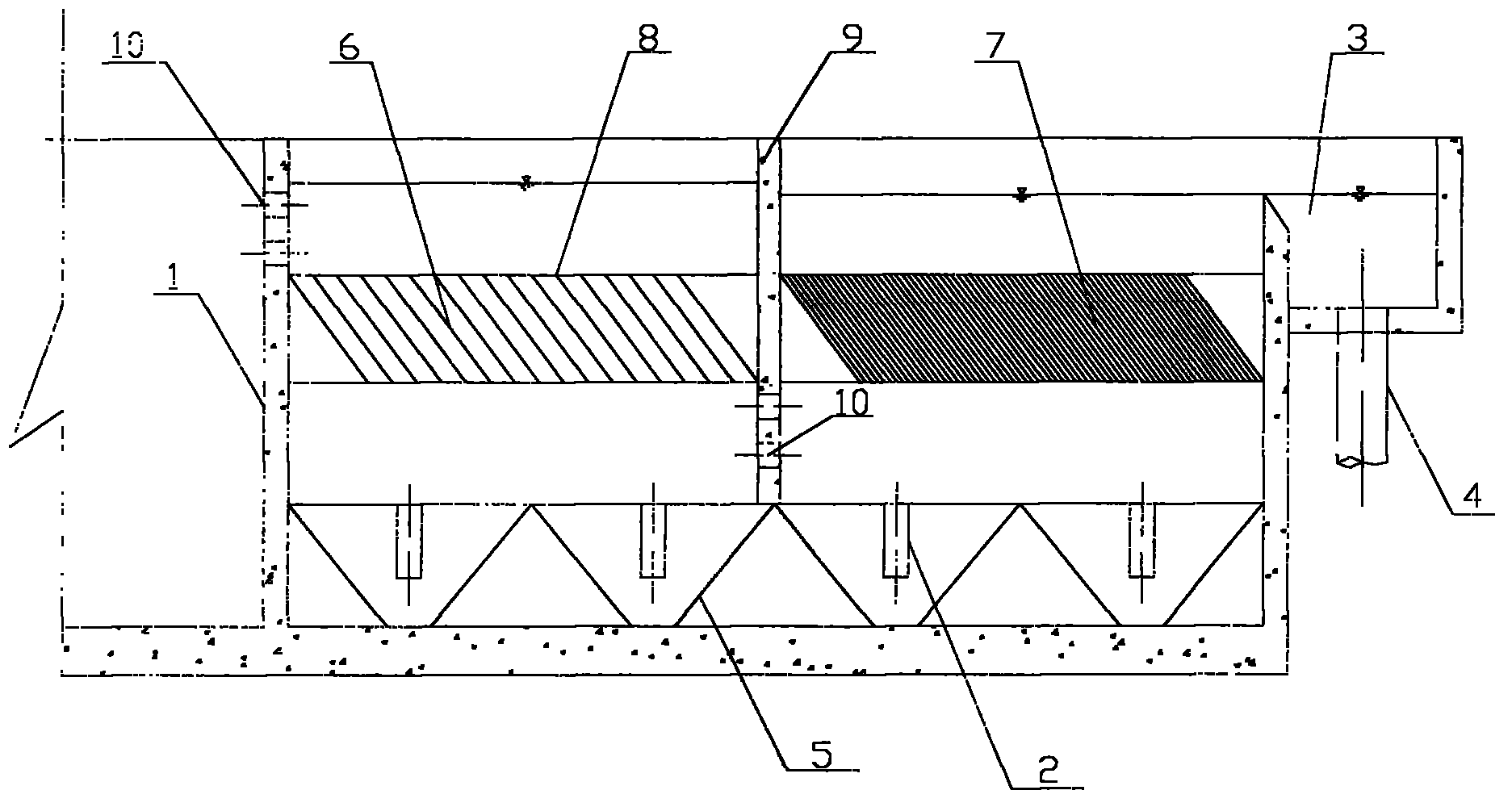

Bidirectional flow variable-spacing inclined plate sedimentation tank

A technology for inclined plate sedimentation and sedimentation tanks, which is applied in the direction of settlement tanks, etc., can solve problems such as complex structures, and achieve the effects of optimized pool structure, improved sedimentation efficiency, and high sedimentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] As shown in the figure, a two-way rheological spacing inclined plate sedimentation tank is adopted. The specific implementation method is as follows: the treated water enters the two-way flow sedimentation tank (1) through the water hole (10), and the two-way flow sedimentation tank (1) is provided with The diversion wall (9), under the action of the diversion wall (9), the treated water first settles in the large particle sedimentation area, and the treated water in this area will pass through the inclined plates (6) with large spacing in the same direction, so that the large particles Particulate matter removal; then the treated water enters the small particle settling zone, where the treated water will pass through the reverse flow small-pitch inclined plates (7), and the small particle matter is removed during this process. The inclined plate devices (6) and (7) are connected by connecting ribs (8). The sediment particles enter the sedimentation hopper (5) through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com