Off-gas ozone treatment method and device

A treatment method, ozone tail gas technology, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve problems such as tail gas damage, and achieve high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

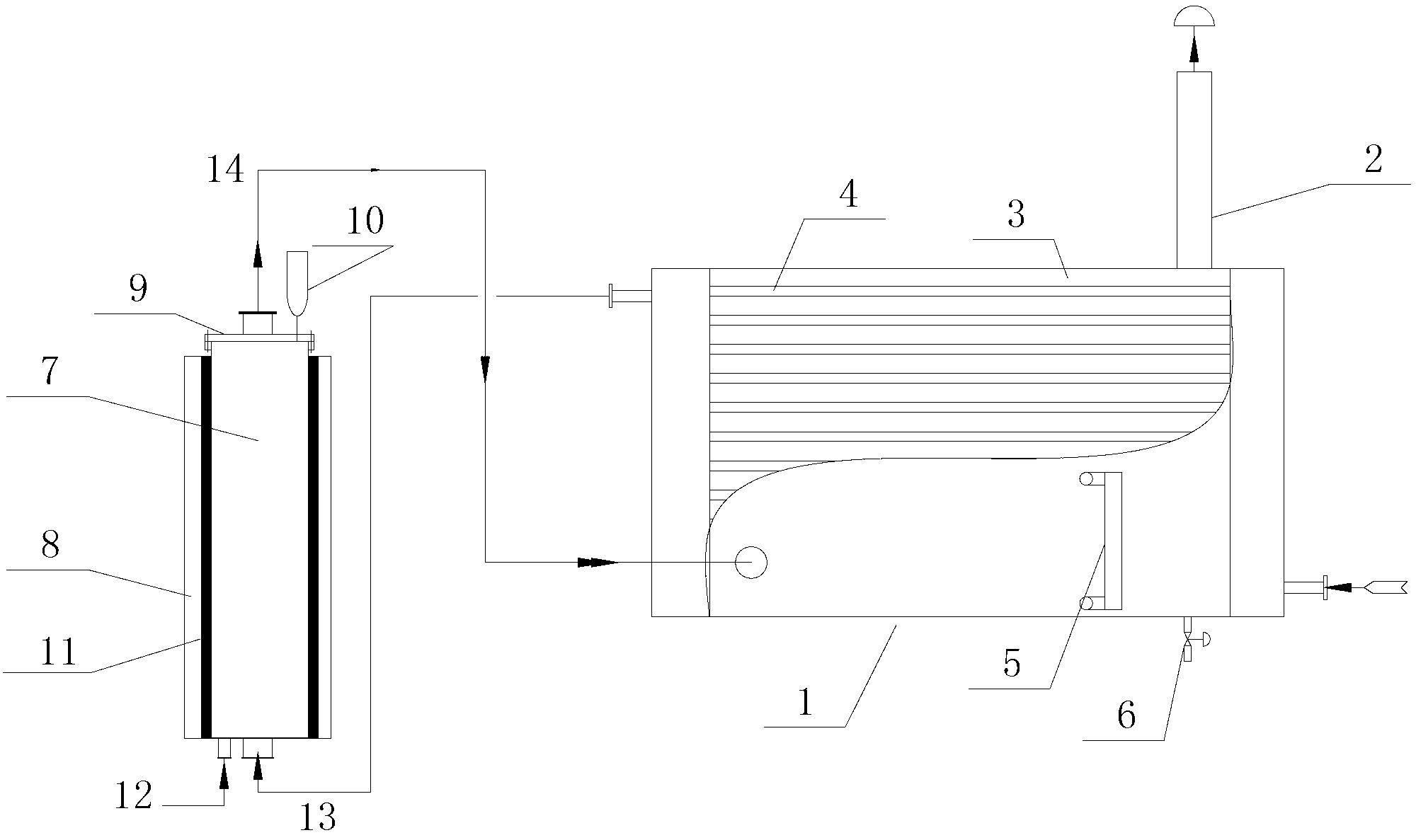

[0040] A treatment device for ozone tail gas, the device is divided into an ozone destruction part and a tail gas cooling part; the tail gas cooling part is composed of a tube-and-tube heat exchanger 1, and the exhaust gas after being cooled by raw material tail gas is finally cooled. After the destruction, the tail gas is connected to the emptying pipe 2 and discharged; in the shell-and-tube heat exchanger 1, the destroyed tail gas goes to the shell side 3, the raw material tail gas goes to the tube side 4, and a liquid level gauge 5 is installed at the bottom to measure the cooling and condensation of the shell side tail gas The water level is high, and it is interlocked with the bottom drain valve 6 to maintain the bottom liquid level of the shell side of the heat exchanger.

[0041]The ozone destruction part includes a steam heating inner cylinder 7, an electric heating outer cylinder 8, a safety top cover 9 and an exhaust valve 10; the steam heating inner cylinder 7 includ...

Embodiment 2

[0043] A treatment device for ozone tail gas, the device is divided into an ozone destruction part and a tail gas cooling part; the tail gas cooling part is composed of a tube-and-tube heat exchanger 1, and the exhaust gas after being cooled by raw material tail gas is finally cooled. After the destruction, the tail gas is connected to the emptying pipe 2 and discharged; in the shell-and-tube heat exchanger 1, the destroyed tail gas goes to the shell side 3, the raw material tail gas goes to the tube side 4, and a liquid level gauge 5 is installed at the bottom to measure the cooling and condensation of the shell side tail gas The water level is high, and it is interlocked with the bottom drain valve 6 to maintain the bottom liquid level of the heat exchanger shell side.

[0044] The ozone destruction part includes a steam heating inner cylinder 7, an electric heating outer cylinder 8, a safety top cover 9 and an exhaust valve 10; the steam heating inner cylinder 7 includes a s...

Embodiment 3

[0046] A treatment device for ozone tail gas, the device is divided into an ozone destruction part and a tail gas cooling part; the tail gas cooling part is composed of a tube-and-tube heat exchanger 1, and the exhaust gas after being cooled by raw material tail gas is finally cooled. After the destruction, the tail gas is connected to the emptying pipe 2 and discharged; in the shell-and-tube heat exchanger 1, the destroyed tail gas goes to the shell side 3, the raw material tail gas goes to the tube side 4, and a liquid level gauge 5 is installed at the bottom to measure the cooling and condensation of the shell side tail gas The water level is high, and it is interlocked with the bottom drain valve 6 to maintain the bottom liquid level of the heat exchanger shell side.

[0047] The ozone destruction part includes a steam heating inner cylinder 7, an electric heating outer cylinder 8, a safety top cover 9 and an exhaust valve 10; the steam heating inner cylinder 7 includes a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com