a fixed structure

A fixed structure and fixed groove technology, applied in the direction of clamping, positioning devices, supports, etc., can solve the problems that the pin holes cannot be processed in place at one time, the processing accuracy is not high, and the efficiency is low, so as to reduce the detection cost and respond quickly. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to understand the technical content of the present invention more clearly, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

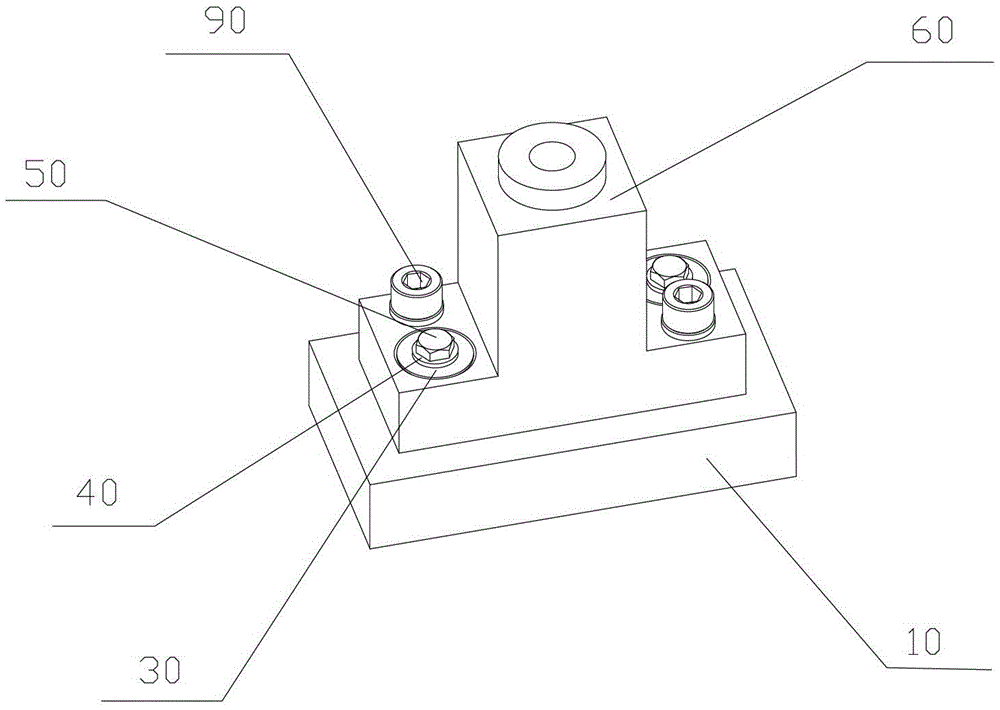

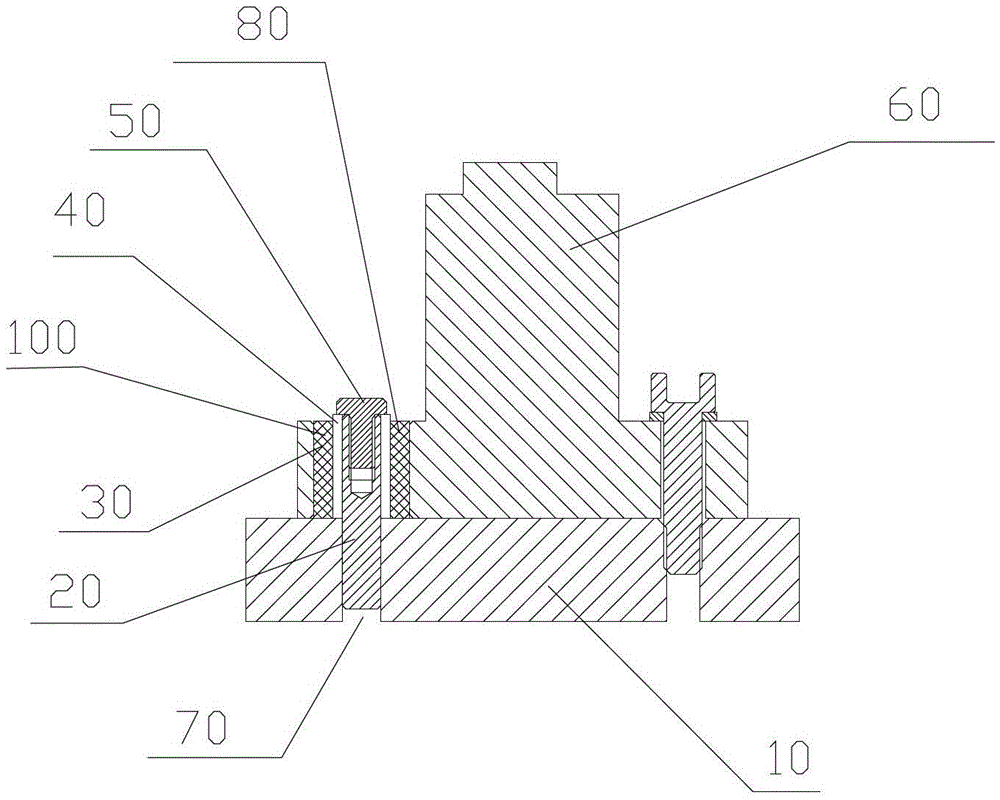

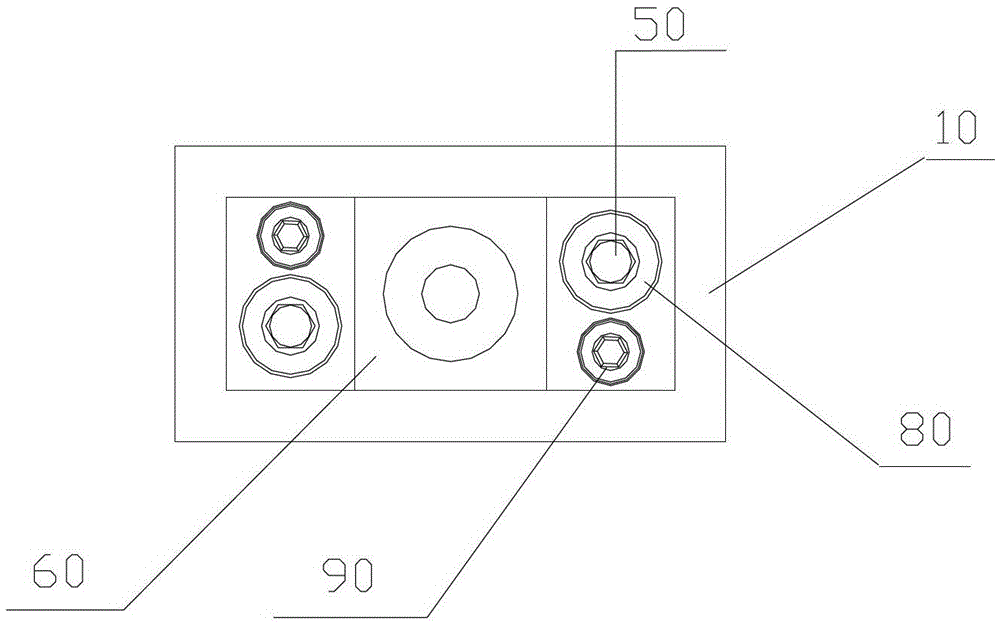

[0035] figure 1 According to the present invention, a schematic structural view of the fixing mechanism is shown, figure 2 shows a sectional view of the fixing mechanism according to the present invention, image 3 A top view of the fixing structure according to the present invention is shown. refer to figure 1 , figure 2 , image 3 , the fixing structure used for processing and fixing two workpieces includes a first workpiece 60, a second workpiece 10, a fastening bolt 90, a positioning pin 20, a colloid 30, a pin bushing 40, a pin cover screw 50, a positioning hole 70, and a fixing groove 80. Wherein, the fixing groove 80 is arranged on the first workpiece 60, the second workpiece 10 is provided with the same positioning hole 70 as the fixing groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com