Composite structure plywood and production method thereof

A technology of composite structure and production method, which is applied in the direction of chemical instruments and methods, layered products, and the joining of wooden veneers, and can solve problems such as poor mechanical properties, reduced physical and mechanical properties, and limited application fields of plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

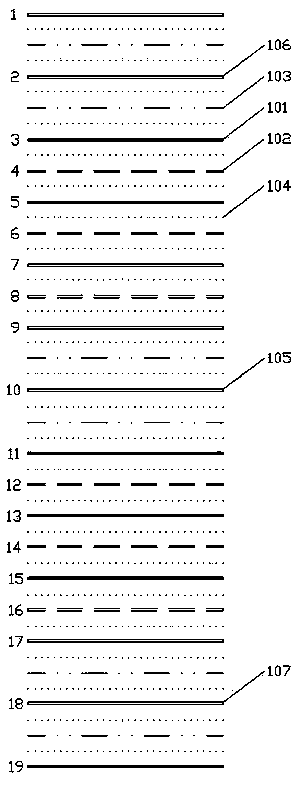

[0021] Such as figure 1 As shown, the composite structure plywood of the present invention includes several layers of veneers formed by laminating along-grain veneers 101 and cross-grain veneers 102 , and the number of veneer layers can be appropriately increased or decreased according to the application occasion and thickness requirements of the product. A plurality of holes are rolled on the veneers, a layer of non-woven fabric 103 is provided between some of the veneers, and polyethylene plastic film 104 is used to glue between adjacent veneers and between veneers and non-woven fabrics. A layer of non-woven fabric 103 is provided on the upper and lower surfaces of the central veneer 105 of the plywood, the upper and lower surfaces of the second veneer 106 from the front, and the second veneer 107 from the back. The grain directions of the veneers arranged on both sides of the non-woven fabric are parallel to each other.

[0022] In this embodiment, a total of 19 layers of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com