A kind of jet coagulation method of natural rubber latex

A natural latex and jet technology, which is applied in the field of natural latex coagulation and production, can solve the problems of large environmental pollution, high production cost, long production cycle, etc., and achieve the effects of improving production profit, reducing application and emission, and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

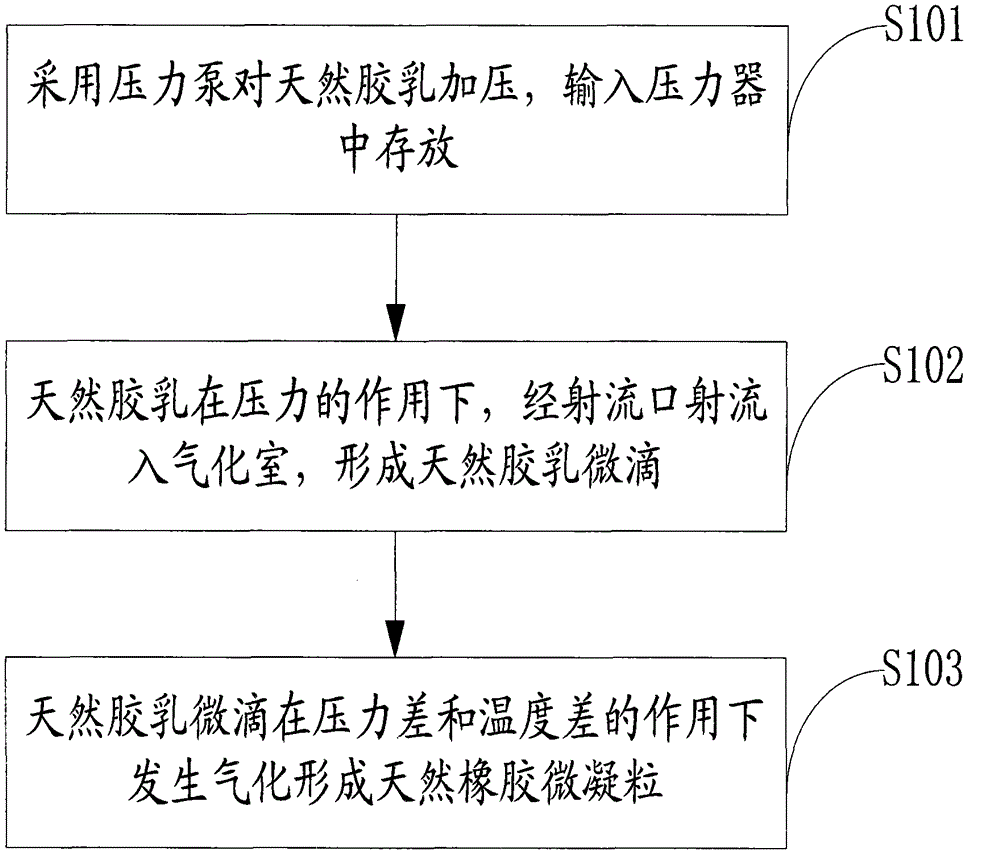

Method used

Image

Examples

Embodiment 1

[0045] The natural rubber latex with a concentration of 40%, an ammonia content of 0.05% and a temperature of 80°C is pumped into the pressure device. The pressure of the natural rubber latex is 1Mpa, and the switch valve is opened to allow the natural latex to flow into the air through a jet port of 0.1 mm. The gasification chamber (the pressure of the gasification chamber is atmospheric pressure) is gasified to form natural rubber wet particles of 0.03-0.08mm.

[0046] The wet particles are collected and dried in a drying equipment at a temperature of 120°C for 70 minutes to obtain natural rubber raw rubber.

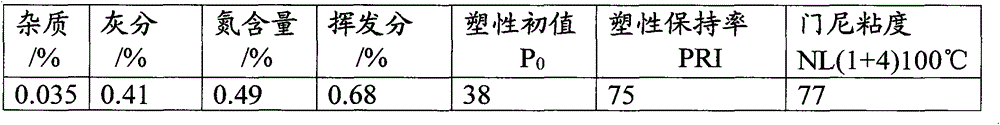

[0047] The physical and chemical properties of natural rubber raw rubber are shown in Table 1.

[0048] The physical and chemical properties of table 1 natural rubber

[0049]

[0050] It can be seen from Table 1 that the physical and chemical properties of the prepared natural rubber raw rubber meet the index requirements of the national standard GB / T8081-2008SCR5...

Embodiment 2

[0052] Concentration is 10%, ammonia content is 0.15% and the natural rubber latex that temperature is 70 ℃, in the pressure device with pump input, the pressure of natural rubber latex is 2Mpa, then the switch valve of continuous pressure device and injection port is opened, makes natural rubber latex It flows into the gasification chamber through a jet port of 0.15 mm (the vacuum degree of the gasification chamber is 0.08Mpa). Gasified to form natural rubber wet particles of 0.05-0.1 mm.

[0053] The wet particles are collected and dried in a drying equipment at a temperature of 120°C for 70 minutes to obtain natural rubber raw rubber.

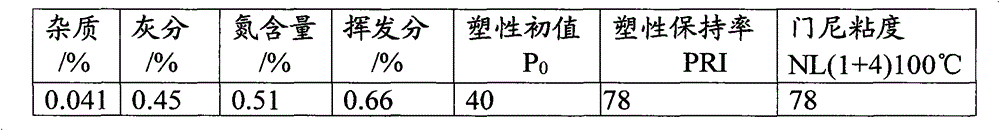

[0054] The physical and chemical properties of natural rubber raw rubber are shown in Table 2.

[0055] Table 2 Physical and chemical properties of natural rubber

[0056]

[0057] It can be seen from Table 2 that the physical and chemical properties of the prepared natural rubber raw rubber meet the index requirements of the national s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com