Polar membrane material with adsorptivity, unidirectional check valve and air bag

A film material and adsorption technology, applied in the field of inflatable bag packaging materials, can solve the problems of uneven distribution, watermark bubbles, poor sealing effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 has adsorptive polar membrane material

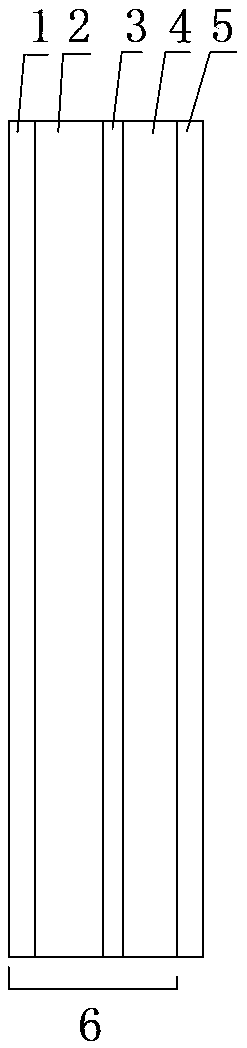

[0027] Adsorptive polar membrane material is a composite membrane structure composed of multiple layers, such as figure 1 As shown, a self-adhesive layer 5 is compounded on one side of the PE substrate 6 to form a single-sided self-adsorbing film material. The self-adhesive layer is PE grafted with maleic anhydride added to EVA. One layer of PE substrate and one layer of self-adhesive layer are the most basic structure of polar membrane material with adsorption.

[0028] Further, the PE substrate can also use multi-layer composite materials, such as figure 1 As shown, the anti-aging protective layer 1 is composed of LDPE layer 4, HDPE layer or MLDPE layer 3, LDPE layer 2, and LDPE+TNPP from the side composited with self-adhesive layer 5. Among them, the HDPE layer or MLDPE layer 3 has higher material strength and rigidity than LDPE, so it can make this polar film material have moderate rigidity, making the film sm...

Embodiment 2

[0031] Embodiment 2 one-way check valve

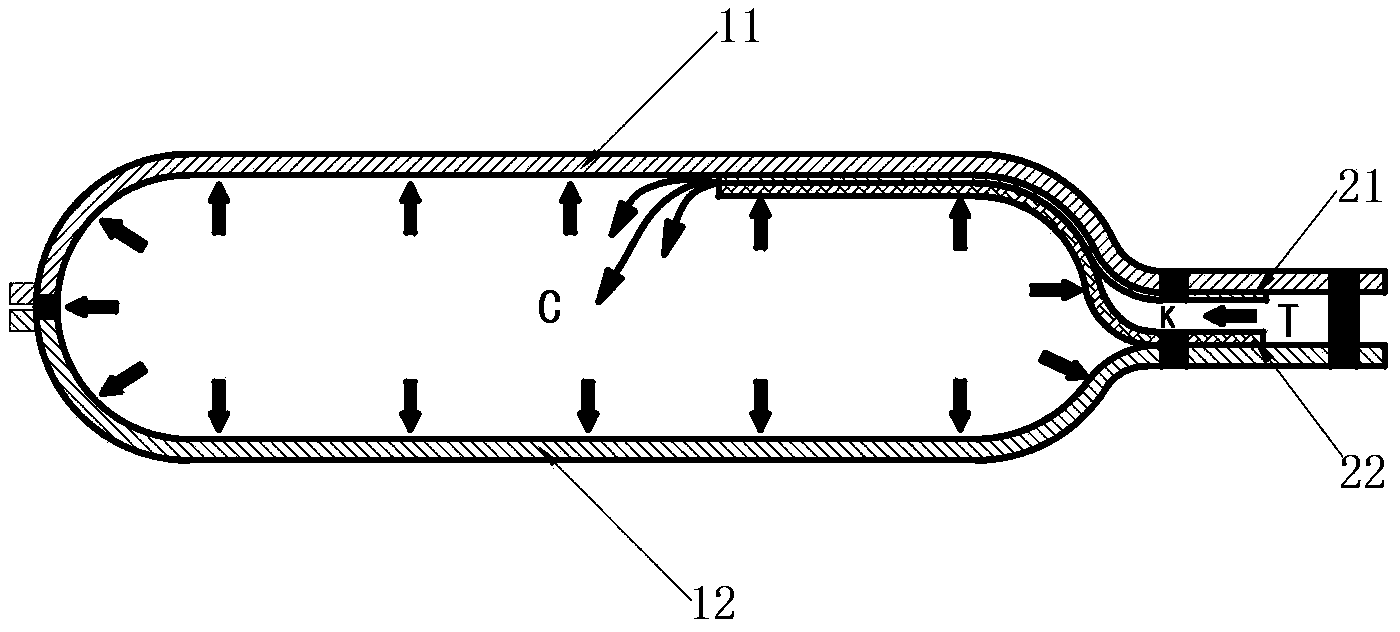

[0032] Such as figure 2 As shown, the one-way check valve is composed of two absorbing polar film materials 21, 22 with one side of the self-adhesive layer facing each other. The absorbing polar film materials 21, 22 all adopt the scheme in Example 1. . The two polar film materials 21, 22 are melted and heat-bonded with the plastic films 11, 12 constituting the bag respectively through the heat-sealing part K in the figure. The opposite sides of the two polar film materials are printed with high-temperature resistant ink, so that the parts forming the air intake channels between the two polar film materials will not be melted and bonded together during heat sealing. When inflating the inflatable bag, the air along figure 2 The inflatable channel T enters the hidden sealing part printed with ink between the polar film materials 21 and 22, and the air pressure overcomes the adsorption force between the self-adhesive layers of the tw...

Embodiment 3

[0034] Embodiment 3 inflatable bag

[0035] Inflatable bag structure such as figure 2 As shown, it includes a bag made of two wider two-layer plastic films 11, 12 through heat sealing, and an inflatable bag one-way check valve formed by two absorbing polar film materials 21, 22.

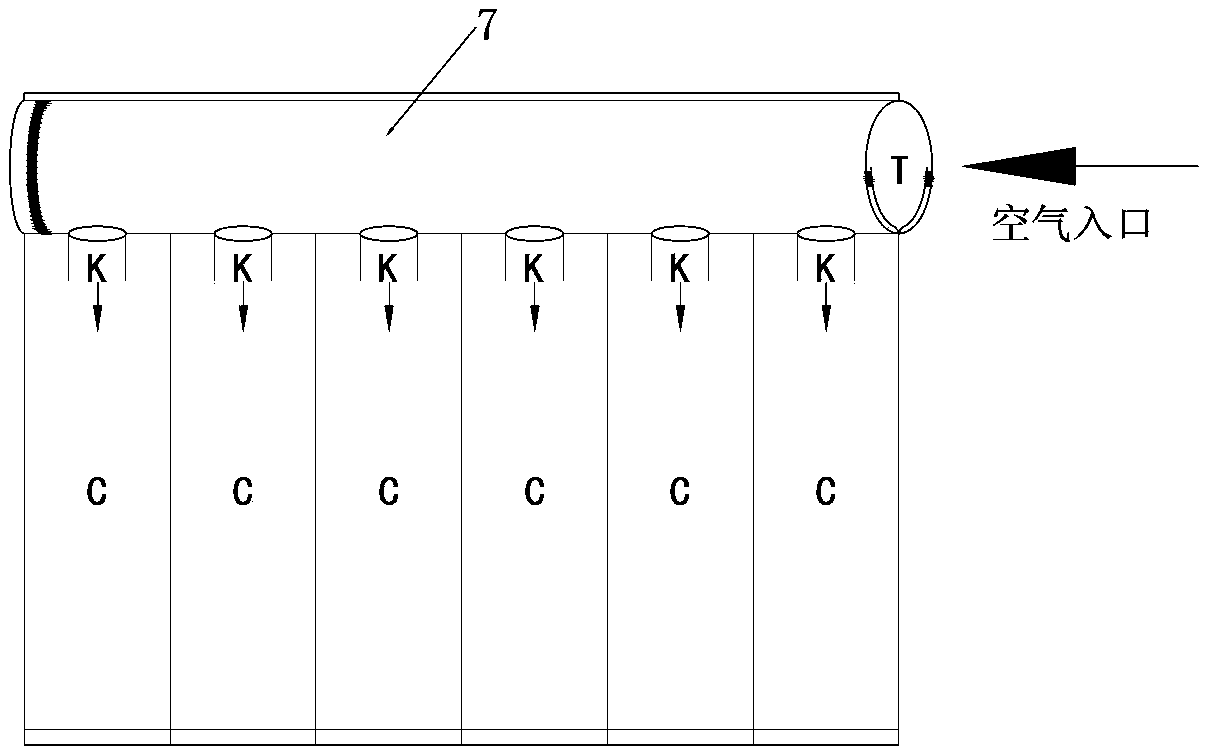

[0036] The air column C that can store media such as air may be a separate space. It can also be constructed for multiple independent inflatable spaces, such as image 3 As shown, the above-mentioned multiple air columns C that can store media such as air have a flute-shaped air intake main passage 7 at the top, and the flute-shaped passage 7 communicates with each independent inflation space through the one-way check valve K, forming multiple air-filled spaces when inflated. connected columns of air. Through different folding and secondary heat sealing, air column bags with different shapes and functions can be formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com