Converter primary flue gas wet type classification dust removing apparatus

A dust removal device and flue gas technology, applied in the direction of manufacturing converters, improving process efficiency, improving energy efficiency, etc., can solve the problems of low operating cost and dust removal efficiency, high one-time investment, and inability to meet environmental protection standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

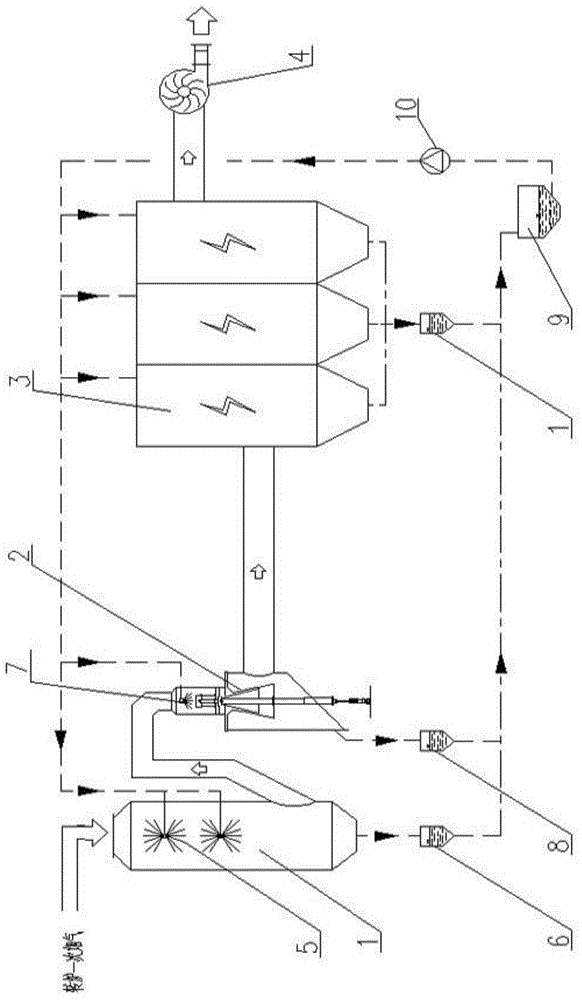

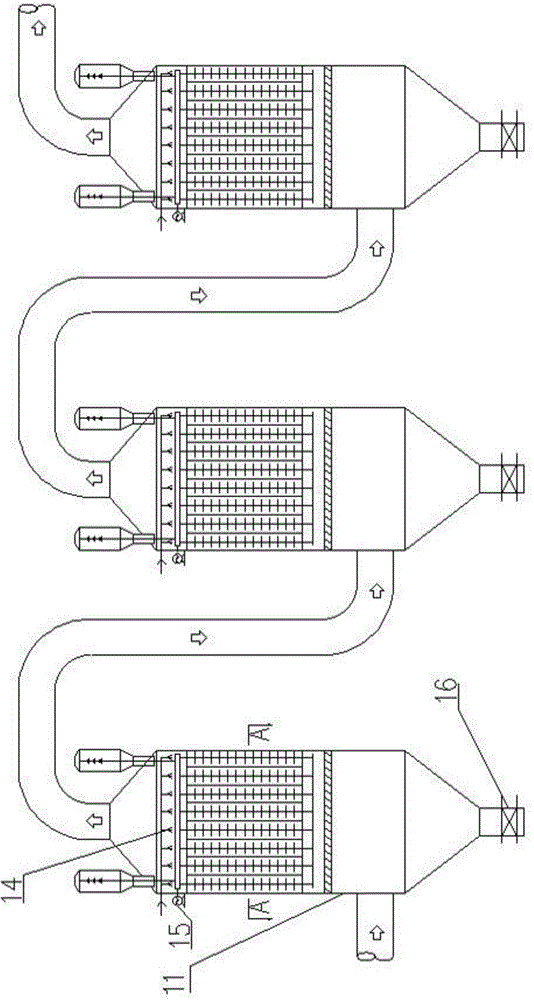

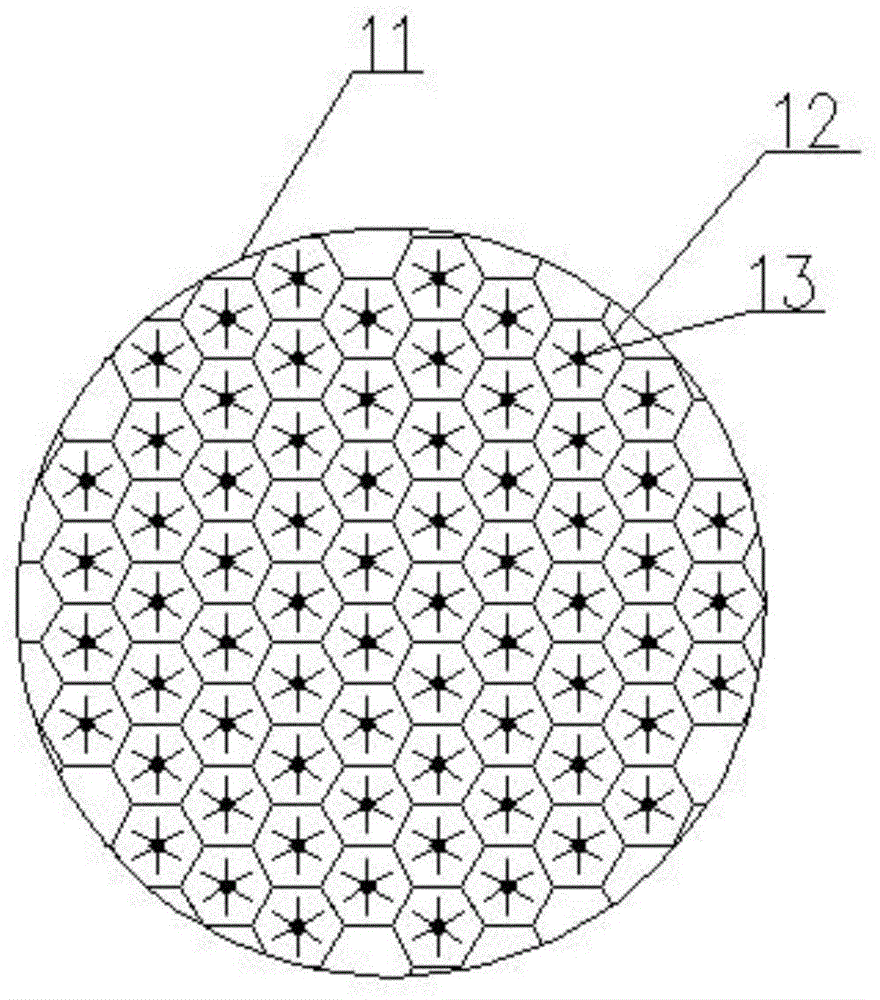

[0020] As shown in the figure, the converter primary flue gas wet classification dust removal device of the present invention includes a first-level rough dust removal device 1, a second-level fine dust removal device 2, a third-level fine dust removal device 3, a fan 4 and a circulating water system connected in sequence. The primary coarse dedusting device 1 is equipped with spraying device I5 and sludge discharge valve I6, the secondary fine dedusting device 2 is provided with spraying device II7 and sludge discharge valve II8, and the circulating water system includes sewage treatment device 9 and circulation pump 10, the sludge discharge valve I6 and sludge discharge valve II8 are respectively connected to the inlet of the sewage treatment device 9, and the outlet of the sewage treatment device 9 is respectively connected to the spray device I5 and the spray device II7 through the circulation pump 10 .

[0021] The high-temperature flue gas generated by the converter firs...

Embodiment 2

[0027] As another embodiment of the present invention, the first-level coarse dust removal device 1 of the present invention is a spray cooling tower, the second-level fine dust removal device 2 is a Venturi tube dust collector, and the third-level fine dust removal device 3 is Electrostatic precipitator and Venturi tube precipitator have good cooling effect on high-temperature gas, and have the advantages of small size, small footprint and low price.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com