Glass fiber air filter paper with antibacterial property and preparation method thereof

An air filter paper, glass fiber technology, applied in filter paper, synthetic cellulose/non-cellulose material pulp/paper, filtration and separation, etc., can solve the problem of rare antibacterial glass fiber air filter paper, and achieve excellent water solubility. , the effect of excellent antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

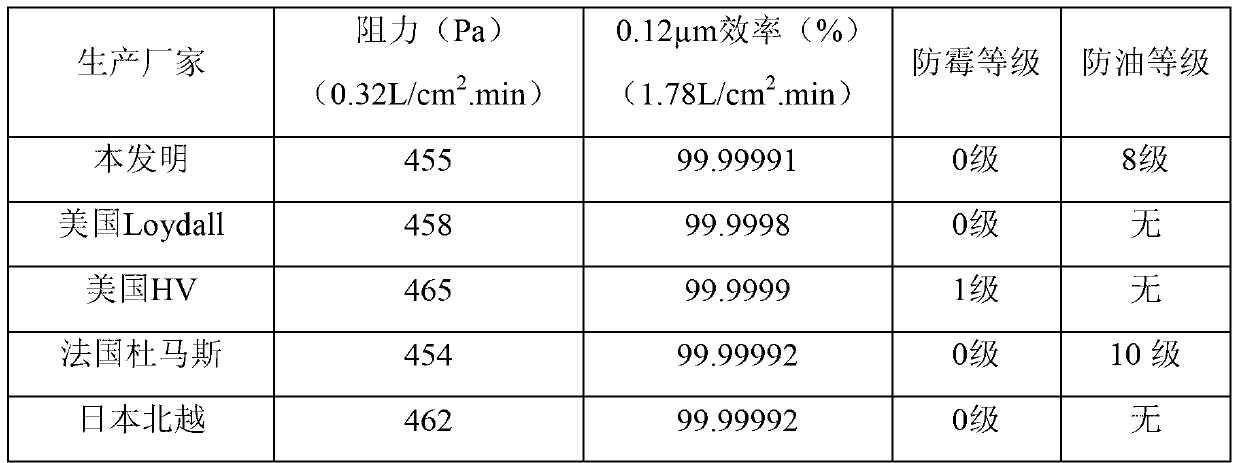

Image

Examples

Embodiment 1

[0028] The method that present embodiment prepares high anti-water nuclear grade glass fiber air filter paper comprises the following steps:

[0029] 1) Select 42 parts of E-glass fiber with a diameter of 0.3 μm, 41.2 parts of E-glass fiber with a diameter of 1.5 μm, 13 parts of E-glass fiber with a diameter of 6 μm, and 3.8 parts of PET polyester fiber;

[0030] 2) Add the selected raw materials into the sulfuric acid aqueous solution to beat and disperse to obtain a slurry, control the mass concentration of the slurry to 6.8%, the beating degree to 38°SR, and the pH value to 3.0, wherein the beating time is 6 minutes, and the motor frequency is 42Hz;

[0031] 3) Add water to dilute the slurry obtained in step 2) to a mass concentration of 4.8%;

[0032] 4) Use a centrifugal deslagging machine to remove slag from the diluted slurry in step 3), and perform wet molding on an inclined wire forming paper machine to obtain glass fiber wet paper;

[0033] 5) Dehydration treatment ...

Embodiment 2

[0037] The method that present embodiment prepares high anti-water nuclear grade glass fiber air filter paper comprises the following steps:

[0038] 1) Select 45 parts of E-glass fiber with a diameter of 0.1 μm, 40 parts of E-glass fiber with a diameter of 1.0 μm, 5 parts of E-glass fiber with a diameter of 5 μm, and 10 parts of PET polyester fiber;

[0039] 2) Add the selected raw materials into the sulfuric acid aqueous solution to beat and disperse to obtain a slurry, control the mass concentration of the slurry to 6.5%, the beating degree to 36°SR, and the pH value to 2.8, wherein the beating time is 5 minutes, and the motor frequency is 42Hz;

[0040] 3) Add water to dilute the slurry obtained in step 2) to a mass concentration of 4.5%;

[0041] 4) Use a centrifugal deslagging machine to remove slag from the diluted slurry in step 3), and perform wet molding on an inclined wire forming paper machine to obtain glass fiber wet paper;

[0042] 5) Dehydration treatment step...

Embodiment 3

[0046] The method that present embodiment prepares high anti-water nuclear grade glass fiber air filter paper comprises the following steps:

[0047] 1) Select 40 parts of E-glass fiber with a diameter of 0.5 μm, 45 parts of E-glass fiber with a diameter of 2.0 μm, 5 parts of E-glass fiber with a diameter of 7 μm, and 3 parts of PET polyester fiber;

[0048] 2) Add the selected raw materials into the sulfuric acid aqueous solution to beat and disperse to obtain a slurry. Control the mass concentration of the slurry to 9.5%, the beating degree to 40°SR, and the pH value to 3.5. The beating time is 7 minutes, and the motor frequency is 42Hz;

[0049] 3) Add water to dilute the slurry obtained in step 2) to a mass concentration of 7.5%;

[0050] 4) Use a centrifugal deslagging machine to remove slag from the diluted slurry in step 3), and perform wet molding on an inclined wire forming paper machine to obtain glass fiber wet paper;

[0051] 5) Dehydration treatment step 4) The o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com