Castellated beam, concrete flitch beam and design method

A technology of composite slab beams and prefabricated concrete slabs, which is applied in the direction of joists, girders, truss beams, etc., can solve the problems of high structural heights that cannot meet the requirements, uneven floors under the floor, and large floor structure heights, etc., so as to facilitate layout Pipelines, on-site operations are convenient, and the surface of the floor is smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

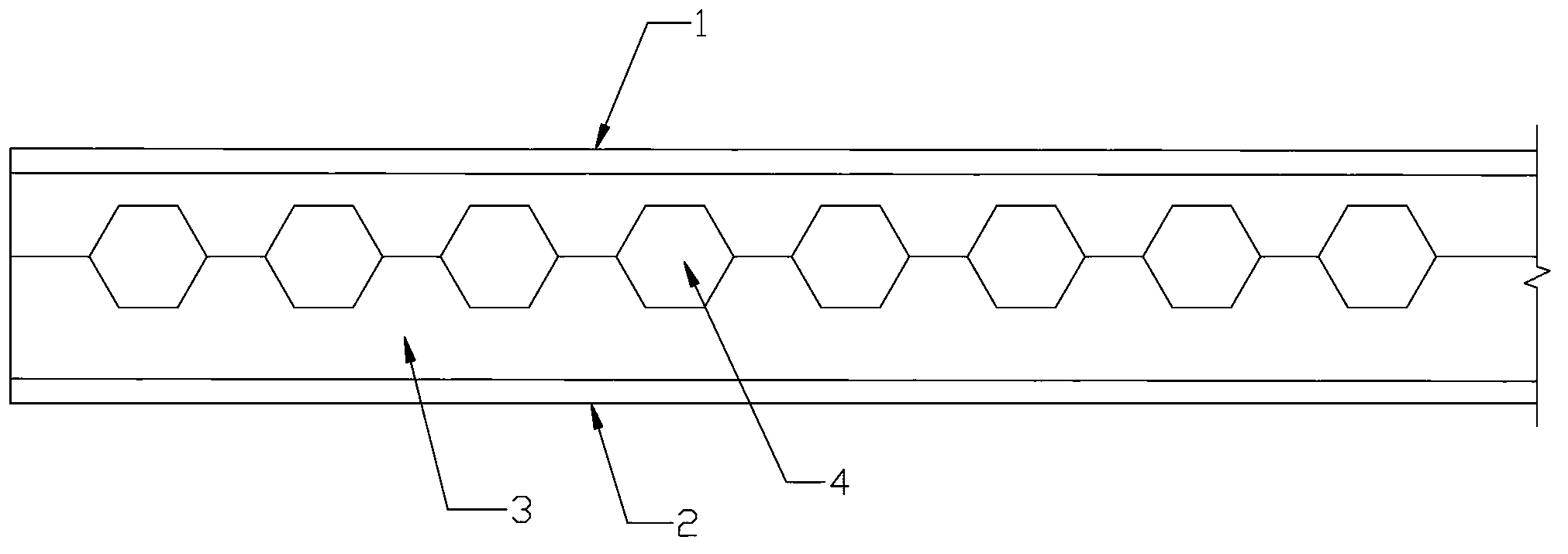

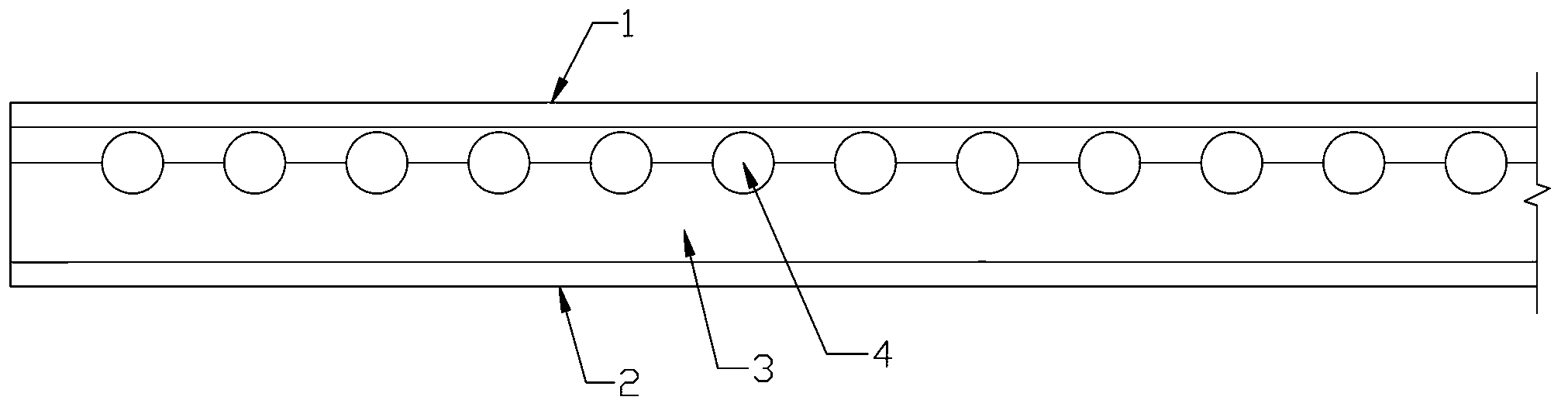

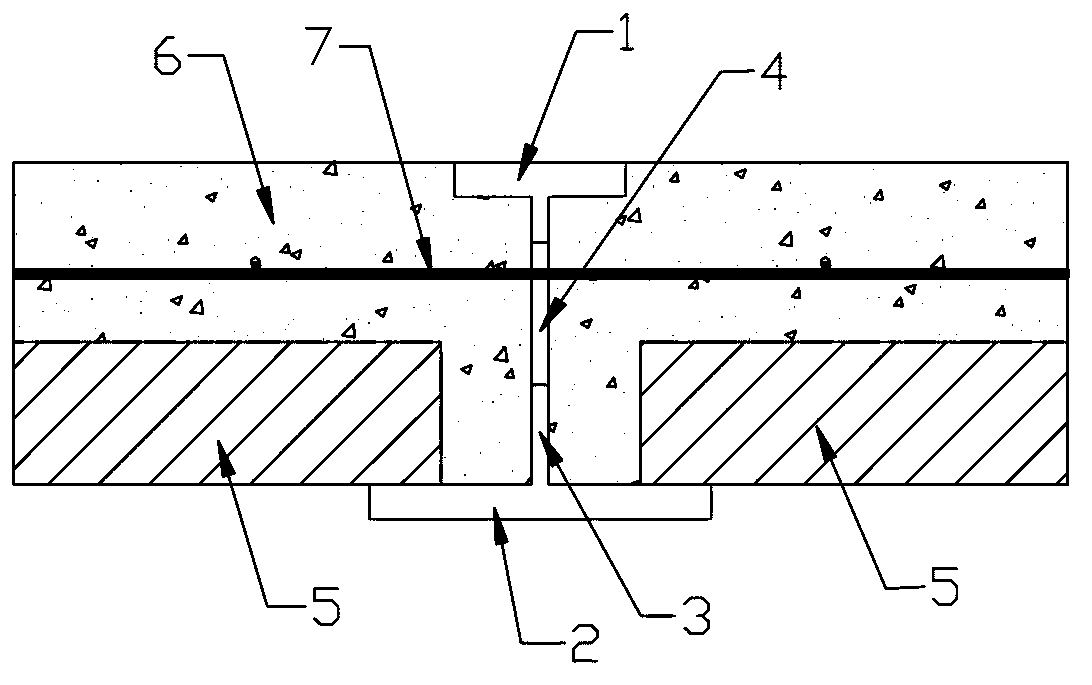

[0025] A honeycomb beam according to the embodiment of the present invention is composed of an upper flange plate 1, a lower flange plate 2, and a web 3 placed between the upper flange plate and the lower flange plate, and a Rows of evenly arranged honeycomb holes 4. The function of the honeycomb holes is to allow reinforcing steel bars to pass through during building construction, so as to provide convenience for construction layout.

[0026] Further explanation as the embodiment of the present invention:

[0027] The width of the upper flange plate is smaller than the width of the lower flange plate. The lower flange plate can be used to set up the precast concrete slab during construction. The web is a vertical single web, or a vertical double web, and there is a gap between the webs.

[0028] Such as figure 1 and figure 2 As shown, the honeycomb holes are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com