Magnetic Suspension Double Wind Wheel Wind Turbine

A wind turbine and magnetic levitation technology, which is applied to wind turbines, wind turbines in the same direction as the wind, and assembly of wind turbines, can solve the problems of poor economy, increased windward area of the nacelle, and large structure, and achieves improved output power, The effect of reducing operating costs and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

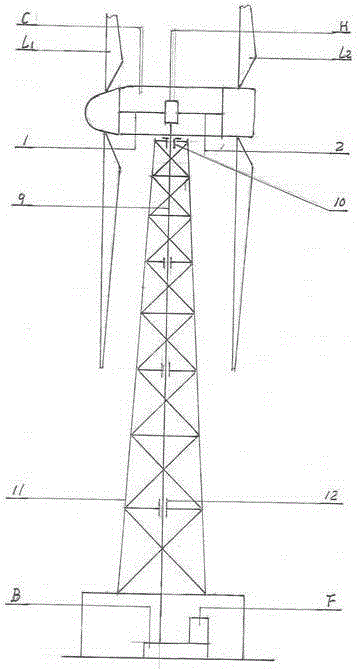

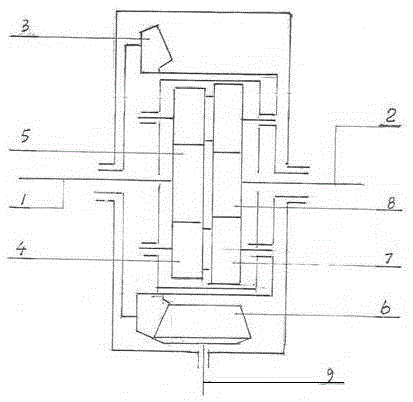

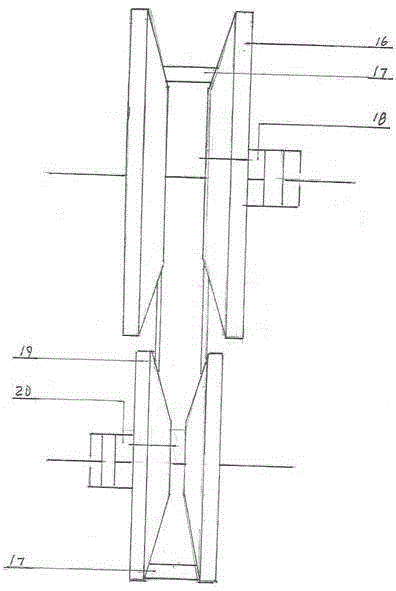

[0029] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a nacelle C erected on the truss tower 11, and the two ends of the nacelle C are respectively equipped with front wind wheels L with the same parameters and opposite directions. 1 and rear wheel L 2 , front wind wheel L 1 and rear wheel L 2 The front wind wheel shaft 1 and the rear wind wheel shaft 2 are respectively connected to the mechanical synthesis mechanism H in the nacelle C, and the mechanical synthesis mechanism H is connected to the variable speed increaser box B at the bottom of the truss tower 11 through the magnetic levitation long axis 9, and the variable speed increaser box B is connected to Generator F; the top of the truss tower 11 is provided with a radial thrust magnetic suspension bearing 10 connected to the magnetic suspension long axis 9, and the inside of the truss tower 11 is provided with a radial magnetic suspension bearing 12 for fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com