Multi-layer low-temperature heat insulation structure arranged in density-variable mode

A technology of low-temperature heat insulation and variable density, which is applied in the direction of heat preservation, heat exchange equipment, and pipeline protection through heat insulation. It can solve the problems of not considering the optimal configuration of internal reflection layers and spacer materials, and the inability to exert heat insulation performance, so as to improve heat insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and the detailed implementation and specific operation process are introduced, but the protection scope of the present invention is not limited to the following Example.

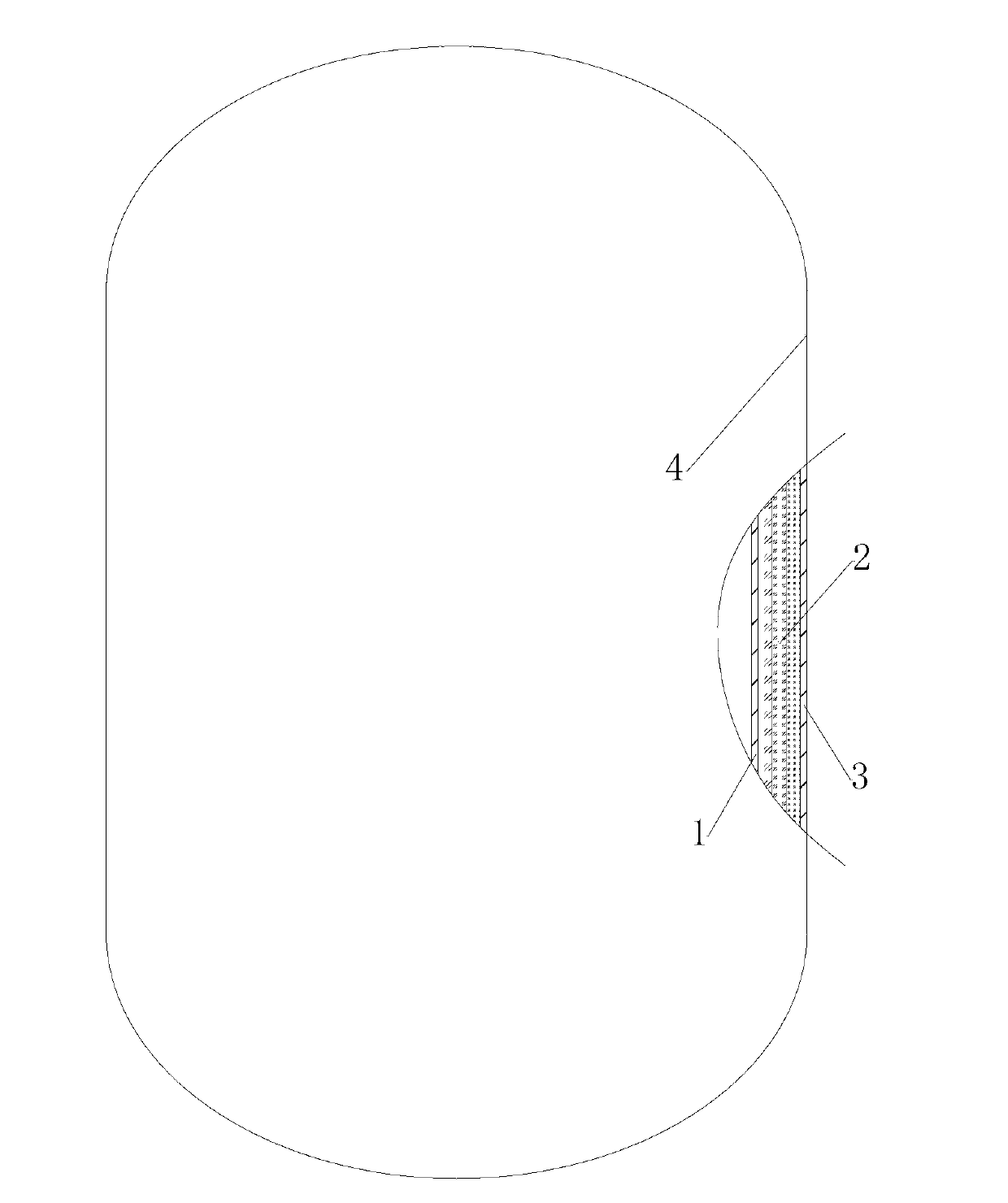

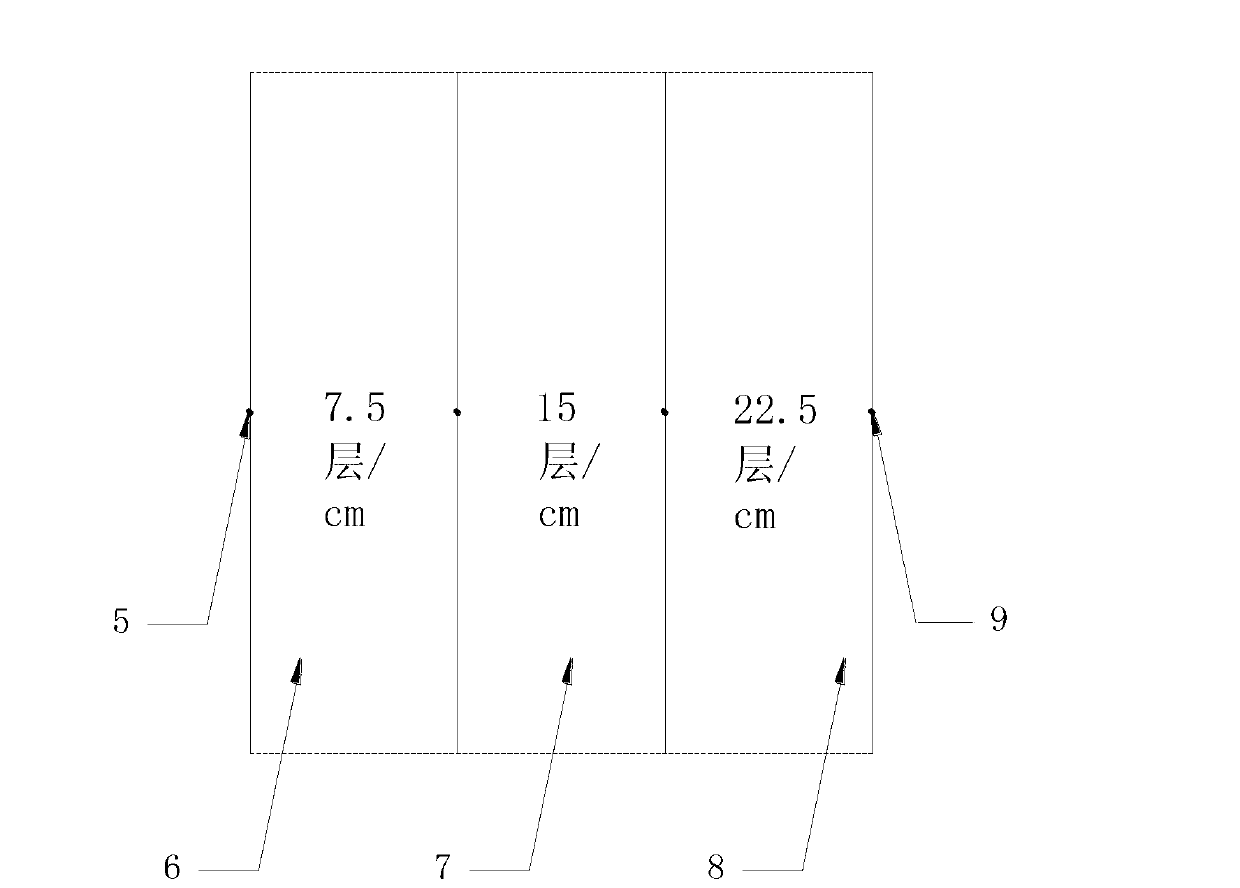

[0017] In the outer vacuum chamber of the low-temperature objects to be insulated (such as cryogenic containers, aerospace low-temperature products, cold heads of cryogenic refrigerators, etc.), according to the specific cold and hot boundary temperature requirements, a certain thickness of variable density multi-layer composite material is covered or wrapped. To achieve a better low-temperature insulation effect than conventional vacuum multi-layer insulation. The multi-layer composite material is laminated with low emissivity reflective layer material and low thermal conductivity spacer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com