Drying system based on heat pipe and use method of drying system

A technology of drying system and hot air system, which is applied in the fields of compounding, coating and printing, and can solve the problems of affecting production cost, large energy consumption of drying system, and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with accompanying drawing:

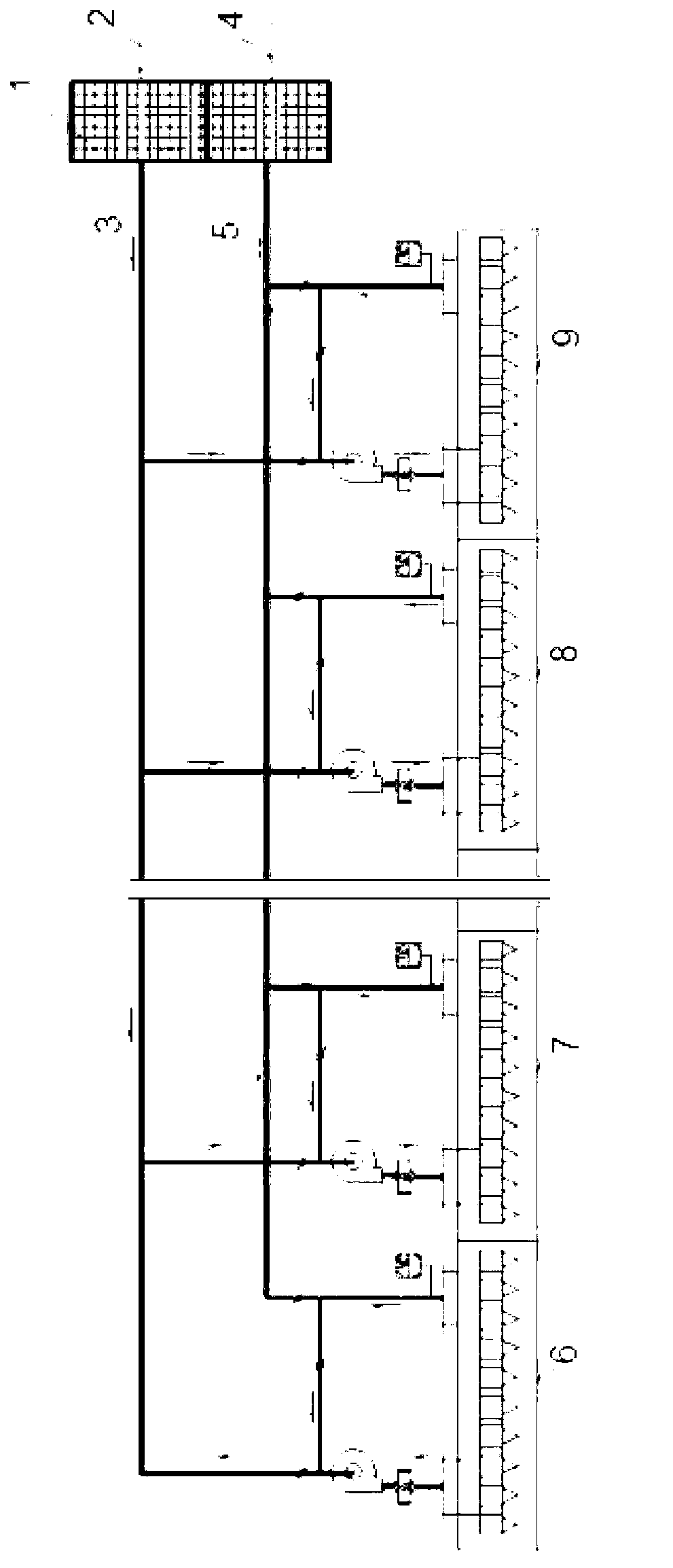

[0015] see figure 1 , when the drying system of the present invention is in operation, fresh hot air enters the drying equipment and is discharged through the exhaust pipe. The exhaust pipe is equipped with a secondary return air device, and a part of the air is directly used in the secondary heat cycle, and the other part is used as a safety exhaust. The amount is exhausted out of the system. As part of the safe air exhaust, a heat pipe heat exchanger is used to efficiently recycle the remaining heat and preheat the fresh air entering the system. The working principle of the heat pipe heat exchanger: the exhaust air passes through the evaporation end of the heat pipe heat exchanger, one end of the heat pipe is heated, the medium liquid in the capillary evaporates rapidly, and the steam flows to the other end (condenser end) under a small pressure difference, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com