Gas sucking type perforated microsphere expanding equipment

A technology for expanding microbeads and gas, applied in the field of machinery, can solve the problems of high added value, complex processing technology, high flexural strength, and achieve the effect of increasing porosity and air permeability, large expansion volume and small bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

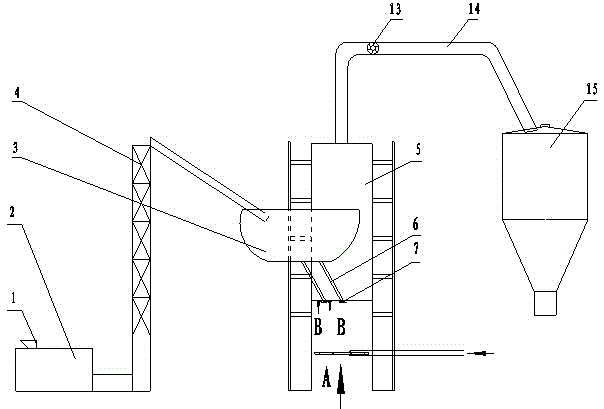

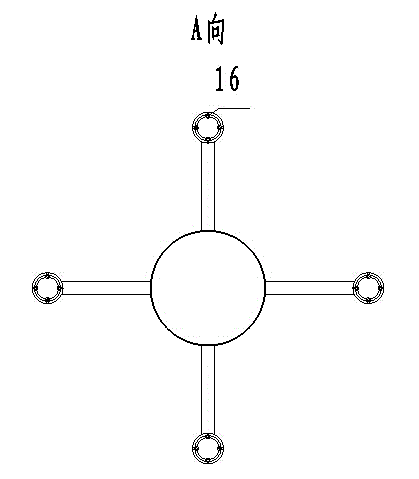

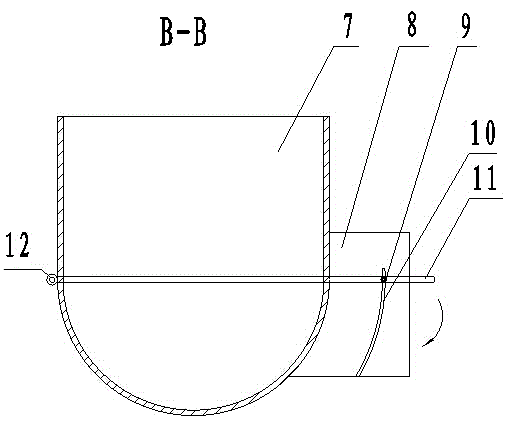

[0018] refer to Figure 1~3 Accompanying drawing further illustrates the present invention.

[0019] Gas suction type open-hole puffed bead equipment, including feed inlet 1, preheating furnace 2, hoist 4, puffing furnace 5, burner 16, induced draft fan 13, product silo 15, preheating Furnace 2 heats up to the set temperature. Because of the large expansion volume, heat preheating furnace 2 to about 360 degrees. Feed port 1 and preheating furnace 2 are located at one end of puffing furnace 5. The heating furnace 2 and the preheating furnace 2 rotate under the drive of the power, and the heated material is continuously turned up and down on the inner wall of the preheating furnace 2, and the material is pushed forward along the spiral direction of the inner wall of the preheating furnace 2, and finally the heated material is lifted by the hoist Machine 4 enters storage bin 3, figure 1 The direction of the arrow in the figure is the direction of the gas inlet, and the burner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com