Integral casting method for stove top refractory lining of hot blast stove

A technology of refractory lining and integral pouring, which is applied in the direction of lining repair, etc., can solve the problems of difficulty in meeting the design life of the furnace, long production process, low construction efficiency, etc., achieve significant social and economic benefits, and excellent thermal shock resistance , The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

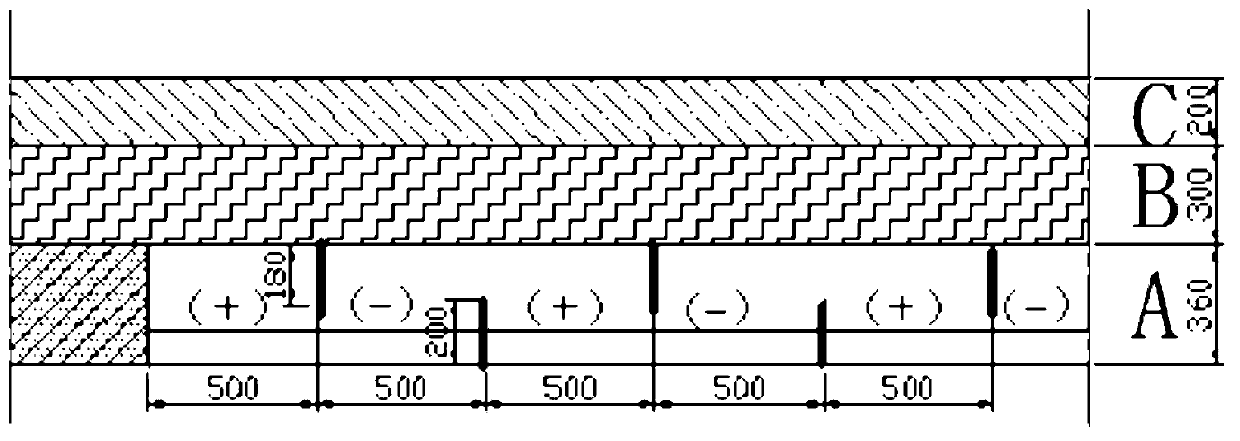

Image

Examples

Embodiment 1

[0046] When the hot air temperature of the hot blast furnace is 1150-1250°C and the working temperature is 1350-1450°C, the pouring method is as follows:

[0047] Step 1 Select GJ-MHL mullite combined with andalusite refractory castable as hot blast stove top castable;

[0048] Step 2 spraying a layer of heat-insulating paint lining inside the steel shell of the hot blast stove roof;

[0049] Step 3 Install the first ring (section) top refractory lining casting mold and wooden partitions in order from bottom to top;

[0050] Step 4 After the mold is installed, pour the refractory lining;

[0051] Step 5 After the pouring is completed, the mold is maintained for 24 hours. After the pouring body is completely solidified, the mold is demoulded and the wooden partition is taken out;

[0052] In step 6, the gap between the cast body and the sprayed layer is covered and the fiber blanket is tightly plugged;

[0053] Step 7. After one ring pouring and fiber blanket plugging are co...

Embodiment 2

[0082] The working condition of the refractory lining on the top of the hot blast stove is that the hot air temperature is 1050-1150°C and the working temperature is 1250-1350°C. The pouring method is as follows:

[0083] Step 1 selects GJ-MLZ mullite combined with aluminum-zirconium refractory castable as the top castable for hot blast stove;

[0084] Step 2 spraying a layer of heat-insulating paint lining inside the steel shell of the hot blast stove roof;

[0085] Step 3 Install the first ring (section) top refractory lining casting mold and wooden partitions in order from bottom to top;

[0086] Step 4 After the mold is installed, pour the refractory lining;

[0087] Step 5 After the pouring is completed, the mold is maintained for 12 hours. After the pouring body is completely solidified, the mold is demoulded and the wooden partition is taken out;

[0088] In step 6, the gap between the cast body and the sprayed layer is covered and the fiber blanket is tightly plugged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com