Pneumatic type blueberry picking machine

The utility model relates to a picking machine and pneumatic technology, which is applied in the field of harvesting machinery for pneumatic picking of blueberries to achieve the effects of improving the fruit picking rate, realizing displacement synchronization and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

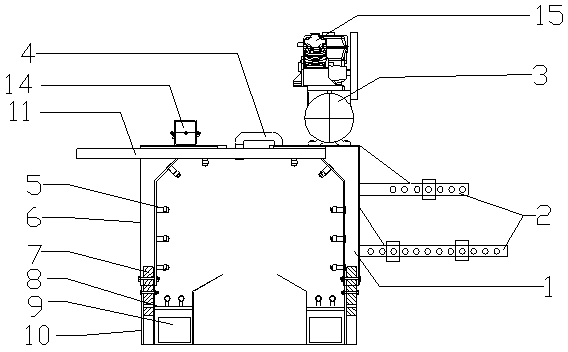

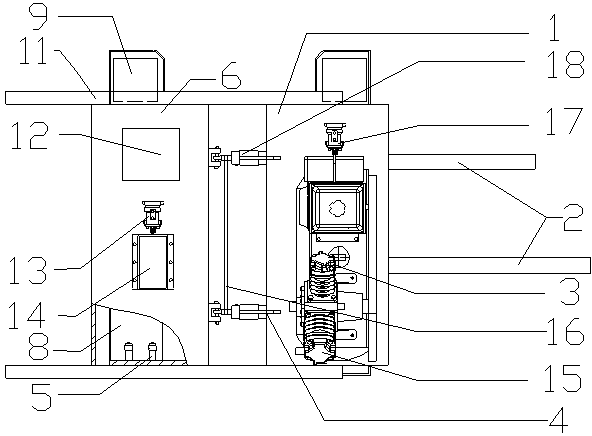

[0021] A pneumatic blueberry picking machine, guide rails 11 are respectively equipped on the front and rear ends of the upper side of the right frame 1, and the left frame 6 is mounted on the guide rail 11 so that it can move left and right, and two hydraulic cylinder brackets 4 are fixed On the upper part of the right frame 1, two hydraulic cylinders 18 cylinder bodies are fixedly mounted on the hydraulic cylinder support 4 and the right frame 1 respectively, and the piston cylinder ends of the two hydraulic cylinders 18 are hingedly connected with the left frame 6 respectively, The piston rods of the two hydraulic cylinders 18 are connected by a rigid beam 16; the air compressor 3 with the pneumatic triple piece 15 and the driving hydraulic motor 17 is installed on the upper part of the right frame 1, and is arranged on the outer side of the right frame 1 Suspension frame assembly 2; On the left frame 6, the hydraulic system control box assembly 12 and the pulse air pressure...

Embodiment 2

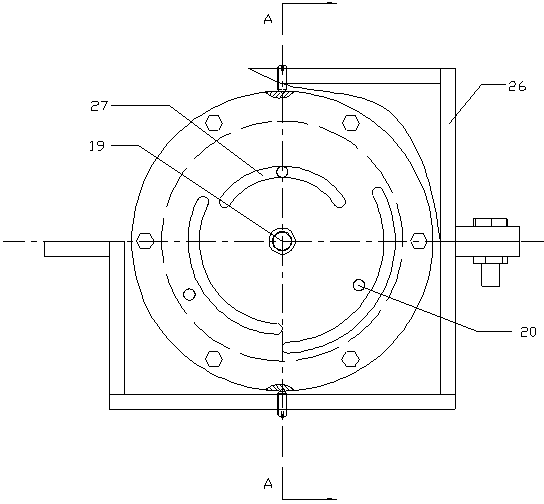

[0023] According to the above-mentioned pneumatic blueberry picking machine, the structure of the pulse air pressure generating device 14 is: on the front sealing disc 21, utilize the sealing gasket 22 to seal the sealing disc 23 after fitting, and seal the front sealing disc 21 and the rear sealing disc 23 on the front sealing disc 21 Three air inlets 20 and three air outlets 24 are respectively arranged at three different diameters and sizes of the same center on the disk 23. The front sealing disk 21 and the rear sealing disk 23 are integrally fixed in the box body 26, and the drive shaft 19 is rotatably mated and installed on the box body 26 and the front and rear sealing discs 21, 23, and the distribution plate 25 is fitted in the cavity formed by the front sealing disc 21 and the rear sealing disc 23. 19 fixed installation, on the distribution plate 25, three arc-shaped windows 27 are opened at three different diameters at the same center at a circumferential angle of 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com