A system and a method for active fire extinguishing and explosion suppression in coal mine workplaces

An active and local technology, applied in fire rescue and other fields, can solve the problems of weak initiative and achieve the effect of convenient operation, wide practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

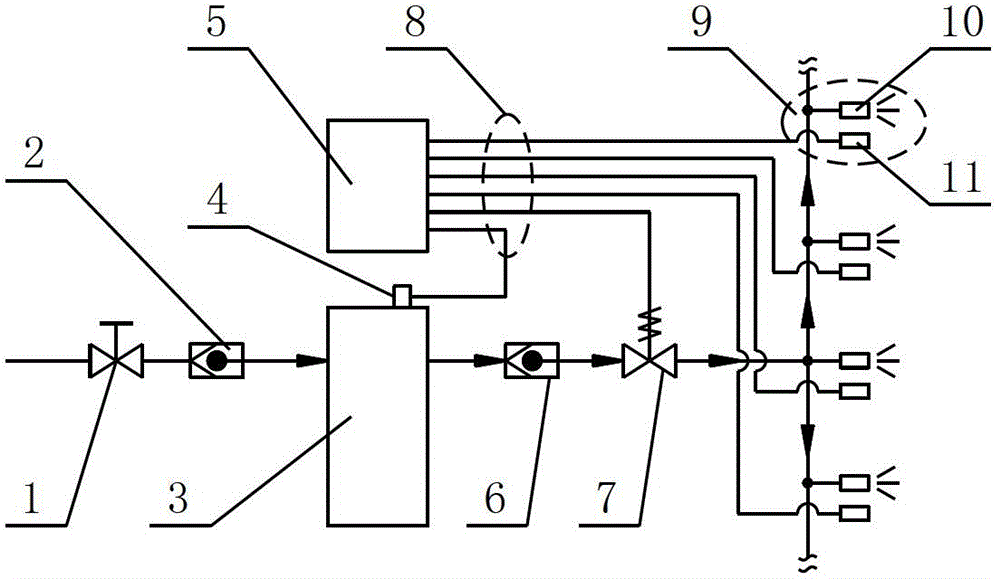

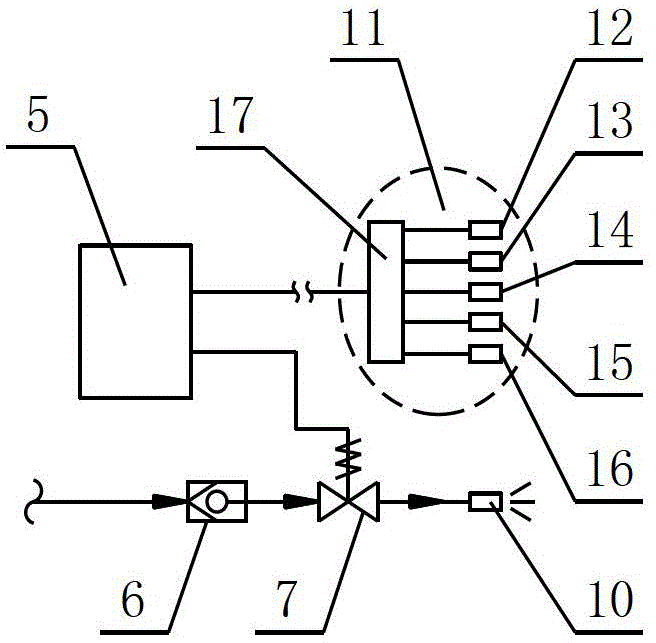

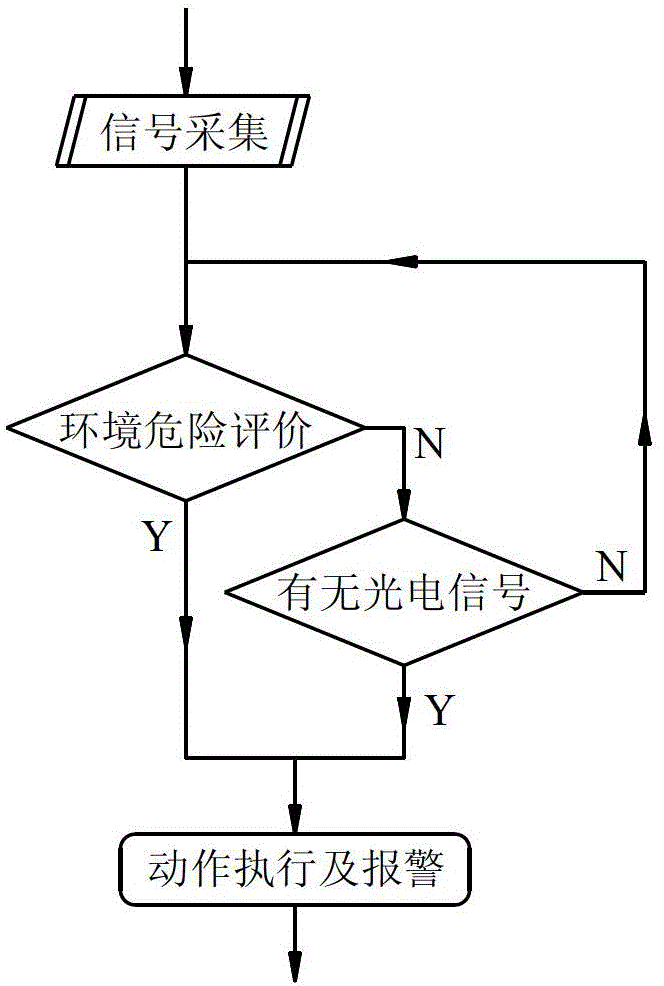

[0019] The active fire extinguishing and explosion suppression system of the coal mine workplace of the present invention mainly consists of the explosion suppression agent filling control valve 1, I check valve 2, high-pressure energy storage tank 3, II check valve 6, and high-speed electromagnetic valve 7 connected in sequence Composition; the storage tank pressure sensor 4 is installed on the high-pressure energy storage tank 3; the signal line of the storage tank pressure sensor 4 is connected with the central control unit 5; the control line of the high-speed electromagnetic valve 7 is connected with the central The control unit 5 is connected; the outlet of the high-speed solenoid valve 7 is connected in parallel with several integrated terminals 9 for fire extinguishing and explosion suppression, and the integrated terminals 9 for fire extinguishing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com