Multi-direction flow gravitational settling apparatus for recirculating aquaculture system

A technology of recirculating aquaculture and gravity sedimentation, which is applied in the field of recirculating aquaculture, can solve problems such as difficult to effectively control the removal effect, complex internal flow state, and influence on sedimentation efficiency, etc., to achieve improved treatment effect, large water treatment capacity, and high removal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

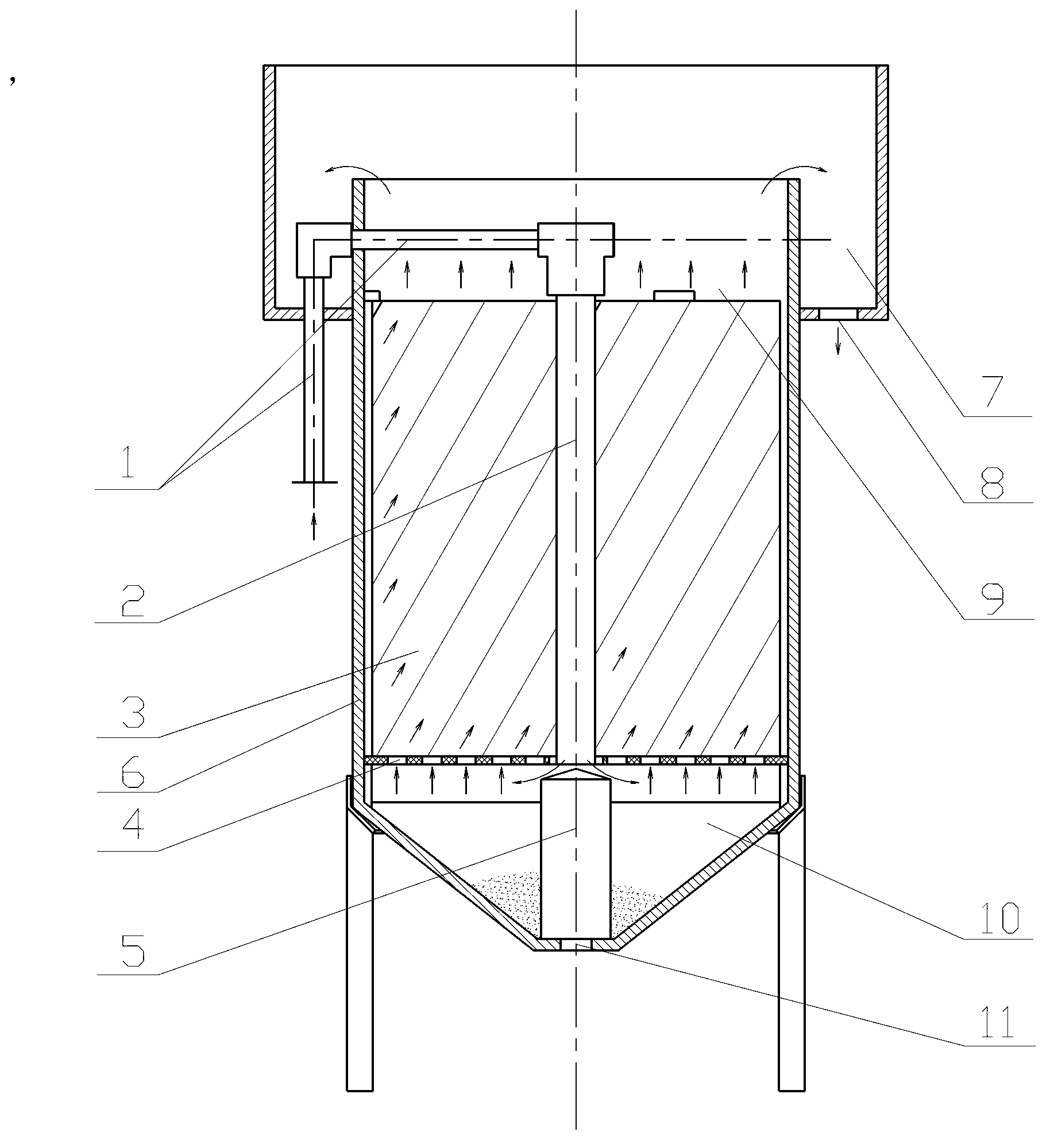

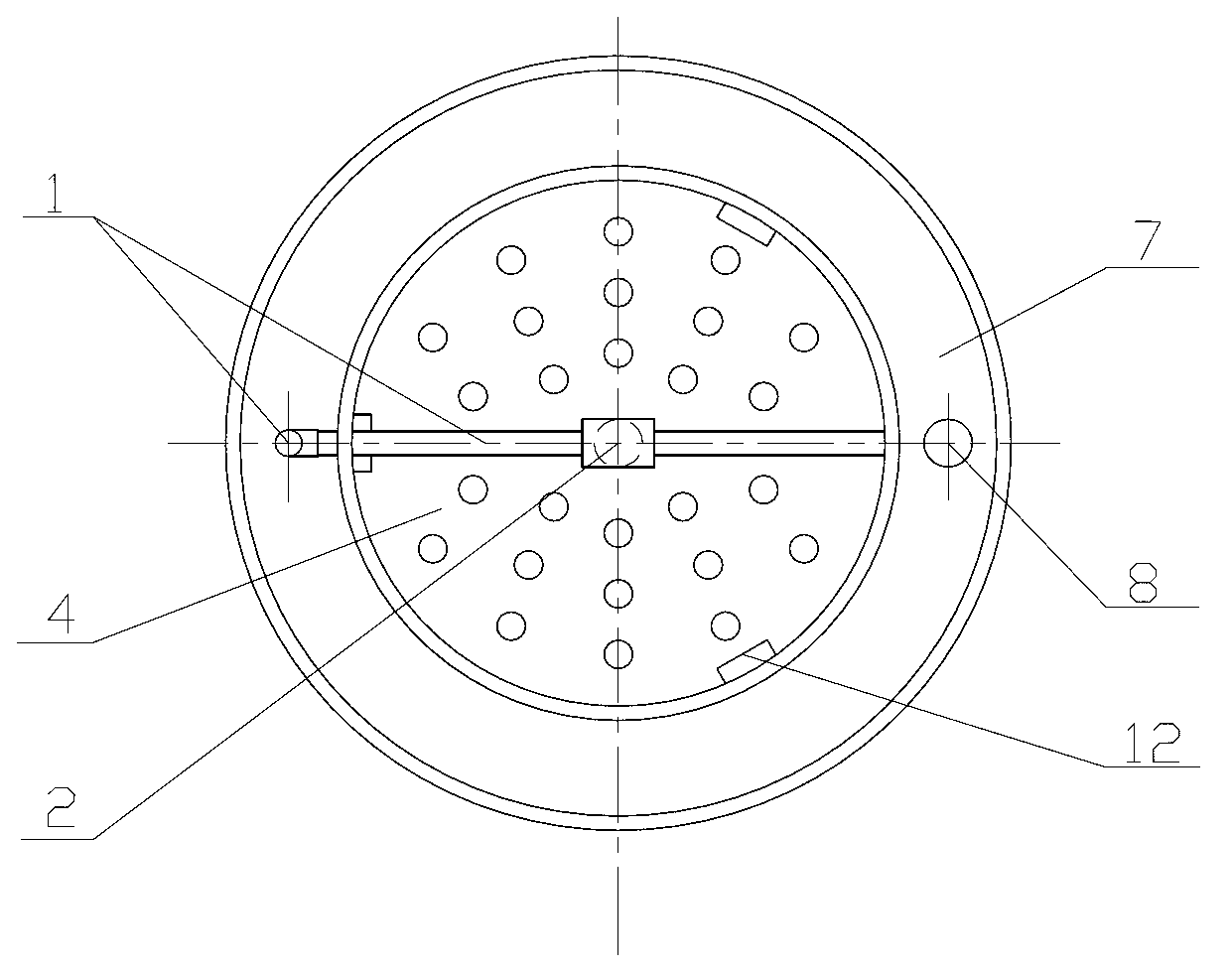

[0033] Figure 1~2 Among them, the vertically arranged barrel-shaped water-passing container 6 is divided into upper and lower two independent chambers by a partition plate 4 arranged horizontally inside it: the straight barrel-shaped sedimentation chamber 9 at the top and the bottom chamber at the bottom The inverted conical sewage collection chamber 10, the dividing plate 4 is an annular flat plate with a central through hole in the center, and a plurality of water holes are provided on the annular plate surface, and the height of the sedimentation chamber 9 is greater than the height of the sewage collection chamber 10.

[0034] The upper end of the water-passing container 6 is an open end, and its end is embedded in a sump 7 with an opening upward. A "7"-shaped water inlet pipe 1 is embedded in the water inlet. The lower end of the water inlet pipe 1 protrudes downward...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com