Diesel engine exhaust particulate matter catalyst, preparation method and application method thereof

A technology of tail gas particles and catalysts, which is applied in the field of catalyst preparation and can solve problems such as reduced reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

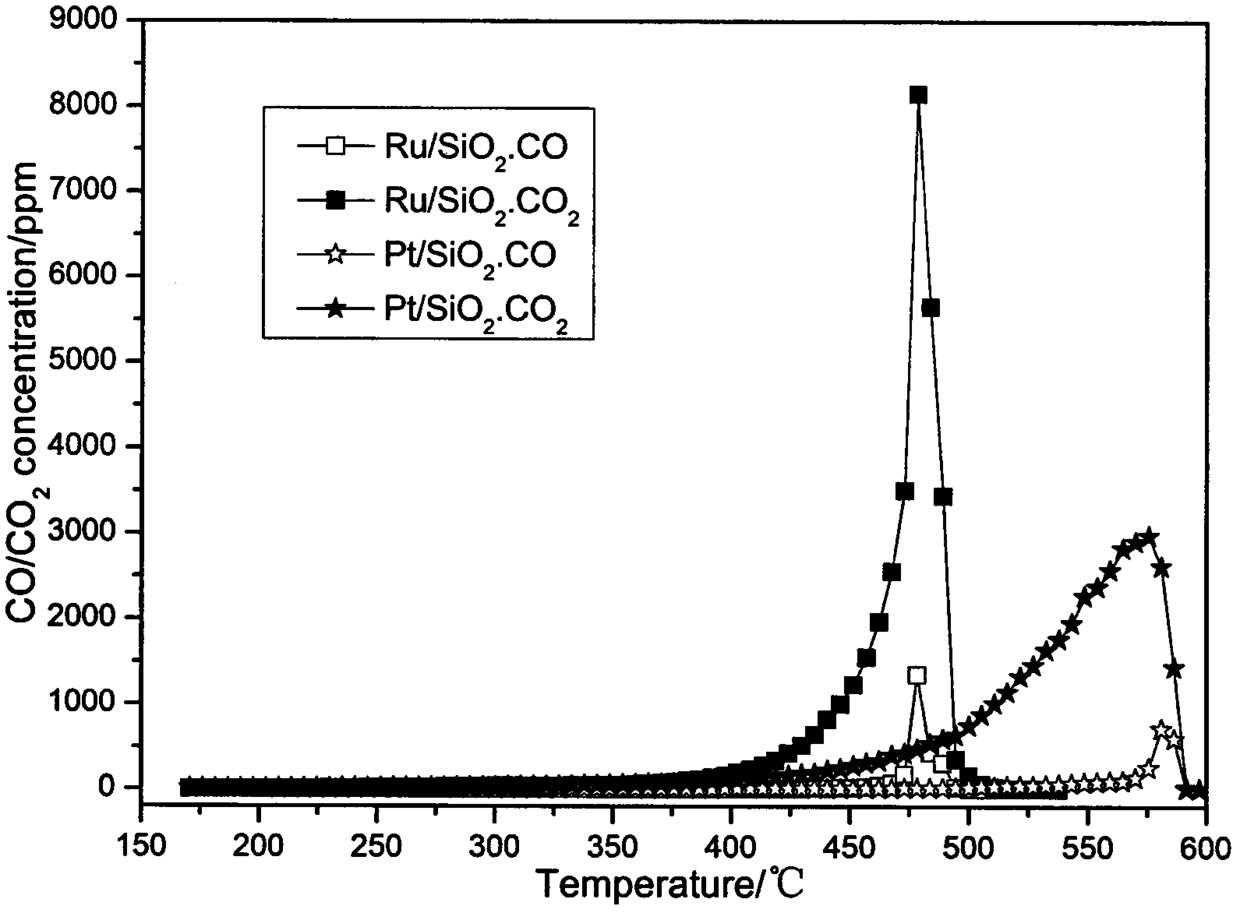

Embodiment 1

[0024] Get the ruthenium trichloride (RuCl3) that contains 0.037g ruthenium 3 ·nH 2 O) prepare the solution, add 3.663g coarse porous microsphere silica gel (SiO 2 ) stirred evenly for equal volume impregnation, after standing at room temperature for 24 hours, dried in air atmosphere at 110°C for 12 hours, and finally calcined in air atmosphere at 500°C for 3 hours to obtain Ru / SiO 2 catalyst. Catalysts of 60-100 mesh were sieved for the catalyst activity evaluation experiment.

Embodiment 2

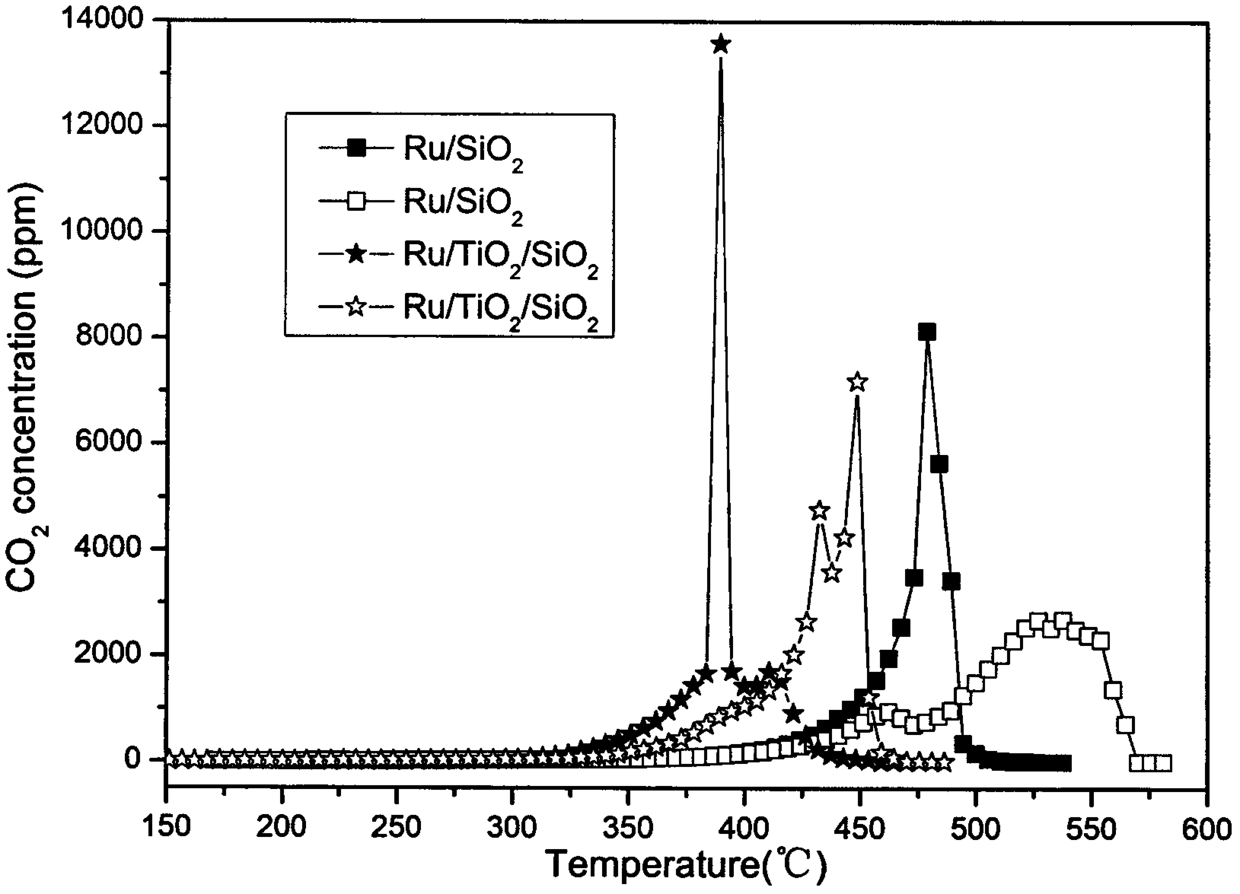

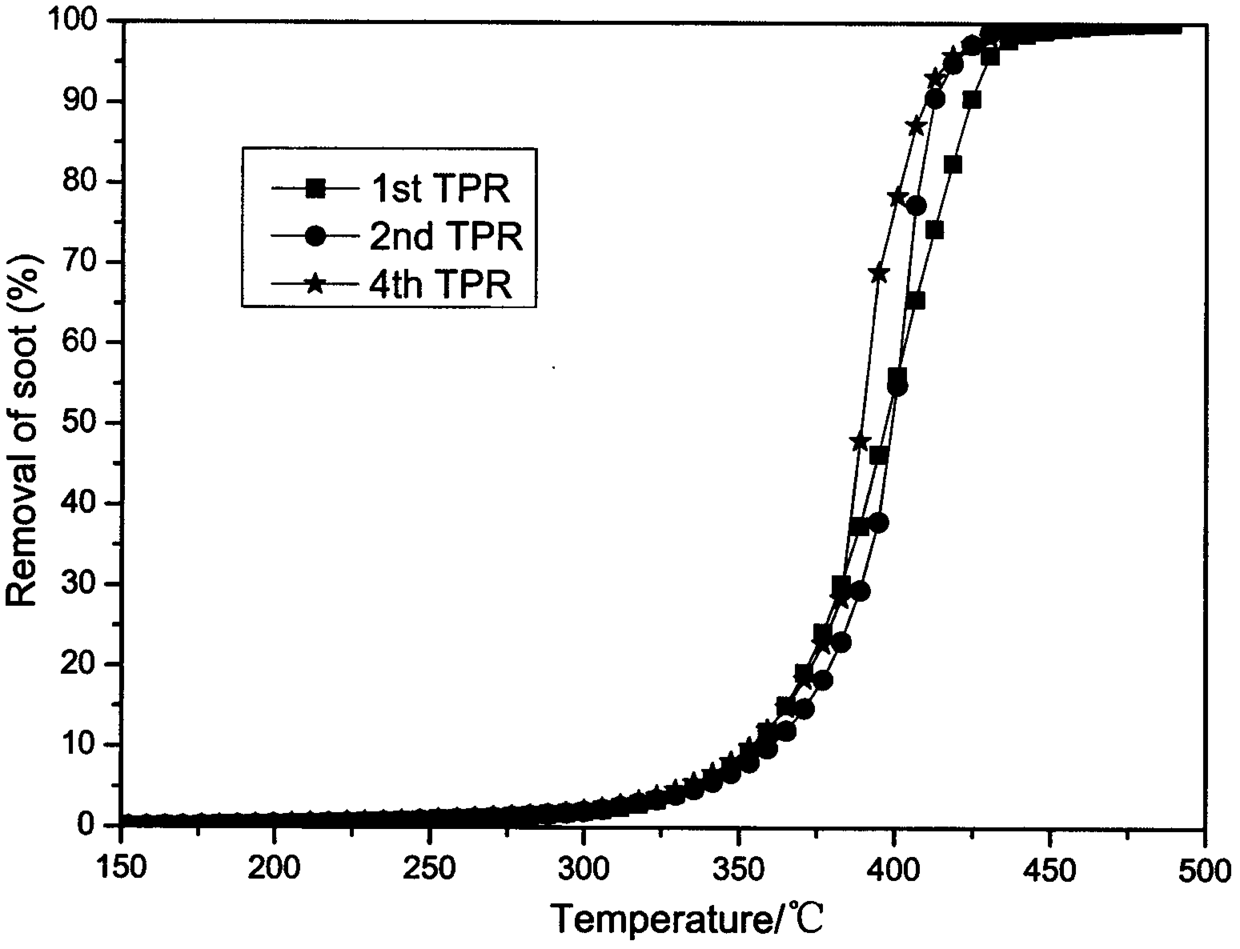

[0028] With the catalyst preparation method of embodiment 1, get and contain 8.0796g titanium sulfate (Ti(SO 4 ) 2 ) to prepare the solution, add 13.9224g coarse porous microsphere silica gel (SiO 2 ) stirred evenly for equal volume impregnation, after standing at room temperature for 24 hours, dried at 110°C for 12 hours in an air atmosphere, and finally roasted at 500°C for 3 hours to obtain TiO 2 / SiO 2 Composite carrier. Sieve the TiO prepared above with 60-100 mesh 2 / SiO 2 Composite support for Ru / TiO 2 / SiO 2 Catalyst preparation. Get the ruthenium trichloride (RuCl3) that contains 0.0259g ruthenium 3 ·nH 2 O) prepare solution, add 2.5641g TiO 2 / SiO 2 The composite carrier was stirred evenly and impregnated with equal volume. After standing at room temperature for 24 hours, it was dried at 110°C in air atmosphere for 12 hours, and finally calcined at 500°C in air atmosphere for 3 hours to obtain Ru / TiO 2 / SiO 2 catalyst. Catalysts of 60-100 mesh were siev...

Embodiment 3

[0030] Adopt the same catalyst preparation method of embodiment 2 to prepare Ru / BaO / SiO 2 、Ru / CaO / SiO 2 、Ru / K2O / SiO 2 and Ru / PbO / SiO 2 catalyst. Catalysts of 60-100 mesh were sieved for the catalyst activity evaluation experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com