A Turning Processing Method for Radial Plate Parts of Integral Impeller Parts

A technology of integral impeller and processing method, which is applied in the direction of turning equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high surface accuracy and roughness, long processing time, etc., and achieve the goal of providing surface quality and prolonging life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A turning processing method for the spoke part of integral impeller parts, aiming at the machining process of the disc profile in the superalloy (GH4169) integral impeller with a diameter of 117-455mm, the cutting tool used is ISCAR coated carbide 35° diamond For the blade, the margin before machining is 1mm, and the margin after machining is 0.4mm. The turning processing method of the radial plate part of this kind of parts is as follows:

[0045] Processing in three steps:

[0046] 1) The first time: the cutting line speed is 20m / min, the feed rate is 0.16mm / r, the cutting time is 45min, and the surface quality is Ra3.2;

[0047] 2) The second time: the cutting line speed is 36m / min, the feed rate is 0.16mm / r, the cutting time is 27min, and the surface quality is Ra1.60;

[0048] 3) The third time: the cutting linear speed is 60m / min, the feed rate is 0.16mm / r, the cutting time is 16min, and the surface quality is Ra1.60.

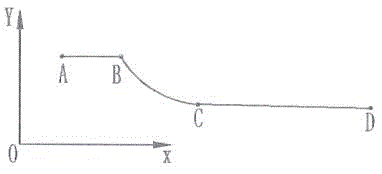

[0049] Will figure 1 As a representative,...

Embodiment 2

[0070] A method for turning the spoke part of an integral impeller part. Aiming at the machining process of the spoke surface of a stainless steel disc body with a diameter of 230-420mm, the tool used is a SANDVIK coated carbide φ12 round blade, and the allowance before machining is 1.5 mm, the margin after processing is 0.3mm. The turning processing method of the web part of this kind of parts is as follows:

[0071] Processing in three steps:

[0072] 1) The first time: the cutting line speed is 36m / min, the feed rate is 0.16mm / r, the cutting time is 20min, and the surface quality is Ra3.2;

[0073] 2) The second time: the cutting line speed is 65m / min, the feed rate is 0.16mm / r, the cutting time is 12min, and the surface quality is Ra1.60;

[0074] 3) The third time: the cutting linear speed is 120m / min, the feed rate is 0.16mm / r, the cutting time is 0.5min, and the surface quality is Ra1.60.

Embodiment 3

[0076] A turning processing method for the spoke part of an integral impeller part. Aiming at the machining process of the spoke plate surface of a titanium alloy integral impeller disc with a diameter of 246-620mm, the cutting tool used is a KENNAMETAL coated carbide 80° rhombic blade. The allowance is 1.5mm, and the allowance after processing is 0.3mm. The turning processing method of the web part of this kind of parts is as follows:

[0077] Processing in three steps:

[0078] 1) The first time: the cutting line speed is 27m / min, the feed rate is 0.16mm / r, the cutting time is 80min, and the surface quality is Ra3.2;

[0079] 2) The second time: the cutting line speed is 50m / min, the feed rate is 0.16mm / r, the cutting time is 45min, and the surface quality is Ra1.60;

[0080] 3) The third time: the cutting linear speed is 68m / min, the feed rate is 0.16mm / r, the cutting time is 32min, and the surface quality is Ra1.60.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com