Low-scratch diamond grinding fluid

A technology of grinding fluid and diamond, applied in the field of grinding fluid, can solve problems such as reducing the qualified rate of processed products, affecting the quality of processed objects, and scratching diamond grinding fluid, so as to reduce polishing procedures and working time, reduce processing costs, and improve removal rate constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 , Preparation of a low-scratch diamond grinding fluid

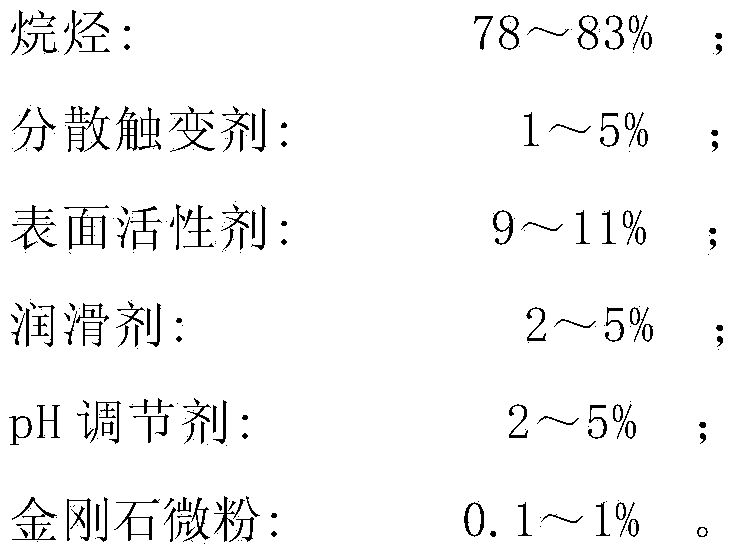

[0023] (1) Selection of grinding liquid formula:

[0024]

[0025]

[0026] (2) Preparation method: put alkanes, dispersing thixotropic agent, surfactant, and lubricant into the mixer according to the above ratio and fully dissolve to obtain a fusion liquid, and then mix diamond particles with a particle size of 1 to 10 μm according to the above ratio Put the micropowder into the fusion liquid and stir, then disperse with ultrasound (500 watts) for 10 minutes to obtain a dispersion liquid, and finally add the above pH regulator to adjust the pH value of the dispersion liquid.

[0027] (3) Scratch detection: Use the above-mentioned prepared abrasive liquid as the polishing liquid to polish 5 pieces of 2-inch sapphire chips on a special polishing machine. The flow rate of the polishing fluid is 2mL / min, the polishing time is 10min, and the polishing rate is 1.8μm / min; after polishing, the surface ro...

Embodiment 2

[0028] Example 2 , Preparation of a low-scratch diamond grinding fluid

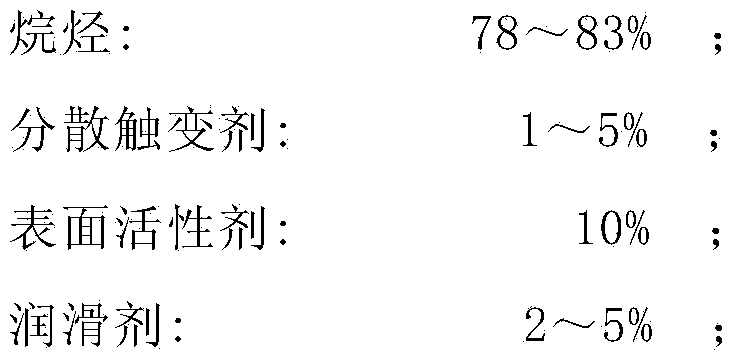

[0029] (1) Selection of grinding liquid formula:

[0030]

[0031] (2) Preparation method: put alkanes, dispersing thixotropic agent, surfactant, and lubricant into the mixer according to the above ratio and fully dissolve to obtain a fusion liquid, and then mix diamond particles with a particle size of 1 to 10 μm according to the above ratio Put the micropowder into the fusion liquid and stir, then disperse with ultrasound (500 watts) for 10 minutes to obtain a dispersion liquid, and finally add the above pH regulator to adjust the pH value of the dispersion liquid.

[0032] (3) Scratch detection: Use the above-mentioned prepared abrasive liquid as the polishing liquid to polish 5 pieces of 2-inch sapphire chips on a special polishing machine. The flow rate of the polishing fluid is 2mL / min, the polishing time is 10min, and the polishing rate is 1.8μm / min; after polishing, the surface roughness of ...

Embodiment 3

[0033] Example 3 , Preparation of a low-scratch diamond grinding fluid

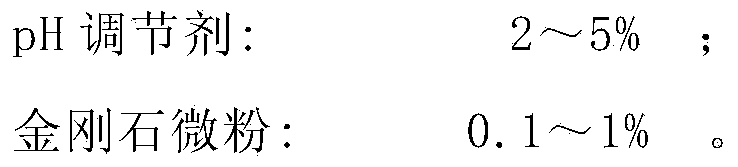

[0034] (1) Selection of grinding liquid formula:

[0035]

[0036]

[0037] (2) Preparation method: put alkanes, dispersing thixotropic agent, surfactant, and lubricant into the mixer according to the above ratio and fully dissolve to obtain a fusion liquid, and then mix diamond particles with a particle size of 1 to 10 μm according to the above ratio Put the micropowder into the fusion liquid and stir, then disperse with ultrasound (500 watts) for 10 minutes to obtain a dispersion liquid, and finally add the above pH regulator to adjust the pH value of the dispersion liquid.

[0038] (3) Scratch detection: Use the above-mentioned prepared abrasive liquid as the polishing liquid to polish 5 pieces of 2-inch sapphire chips on a special polishing machine. The flow rate of the polishing fluid is 2mL / min, the polishing time is 10min, and the polishing rate is 1.8μm / min; after polishing, the surface r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com