A three-phase welding machine circuit

A three-phase power supply and circuit technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low detection accuracy of the detection system, inherent bulkiness of power frequency transformers, and low detection accuracy, and achieve fast and sensitive protection , eliminate power frequency transformers, and achieve high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

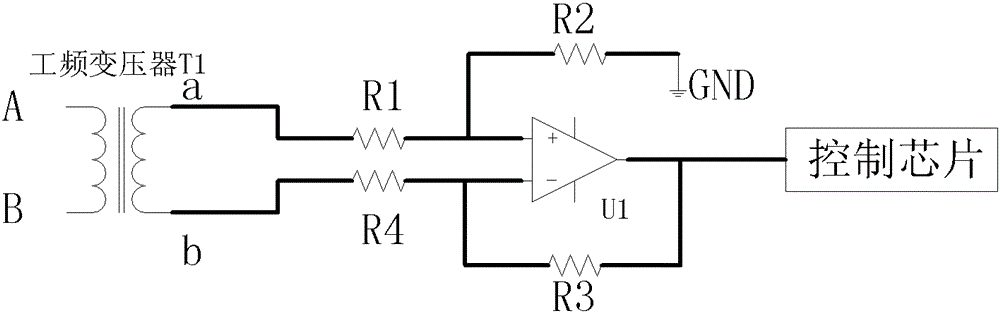

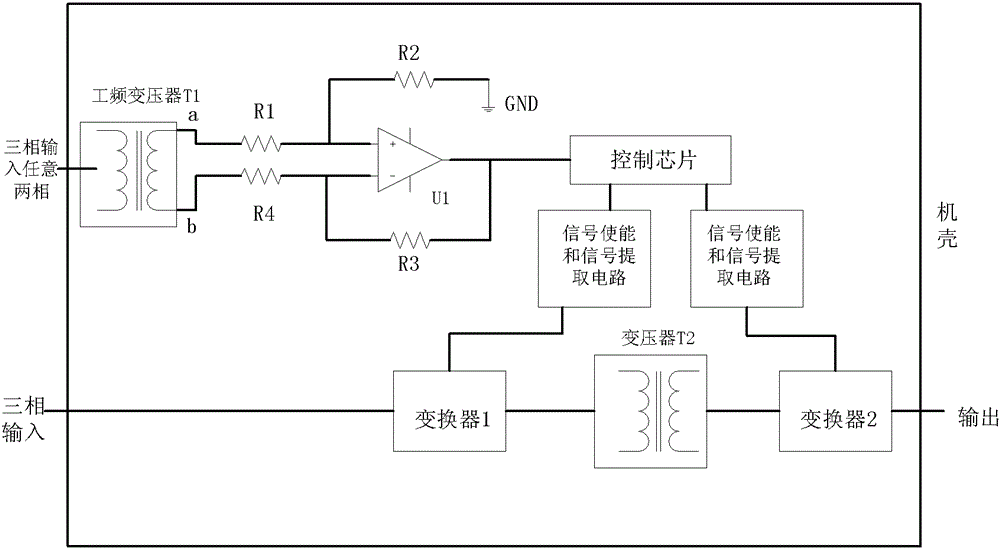

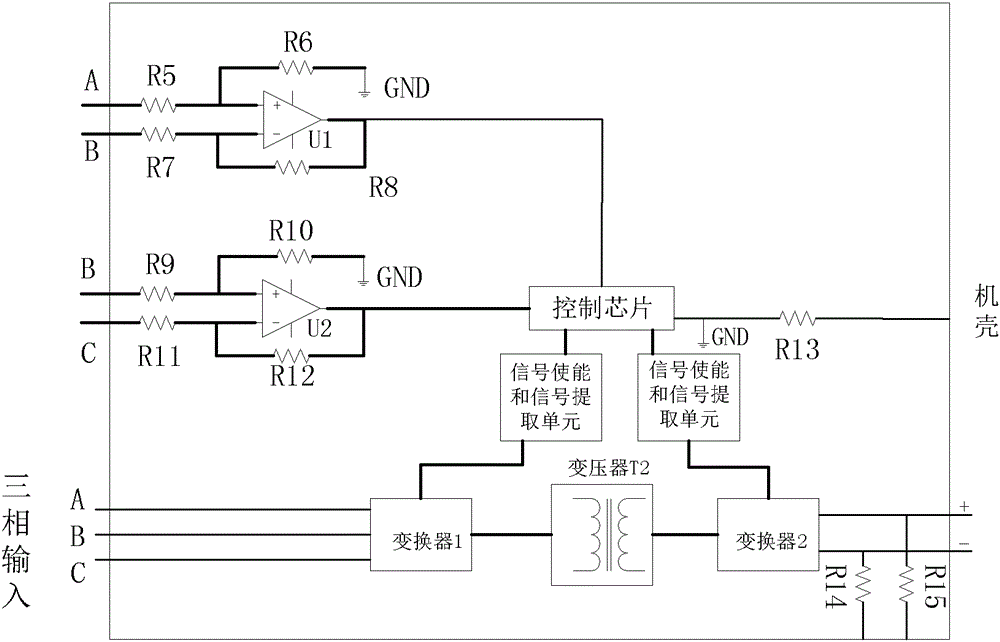

[0031] Such as image 3 As shown, the three-phase welding machine circuit of the embodiment of the present invention includes a main circuit, a differential detection circuit and a control circuit. image 3 Among them, A, B, and C are respectively three-phase AC input terminals, and the chassis is directly connected to the earth.

[0032] The main circuit includes a primary circuit and a secondary circuit coupled with the primary circuit through a transformer. The primary circuit is connected to the input terminal of the three-phase power supply, and the output terminal of the secondary circuit is the output terminal of the welding machine.

[0033] The control circuit includes a control unit and a signal enabling and signal extraction circuit, and the control unit controls the primary side circuit and the secondary side circuit through the signal enabling and signal extraction circuit.

[0034] The signal output terminal of the differential detection circuit is connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com