Air-flotation ultra-precision grinding device and grinding method thereof

An air-floating, grinding tool technology, applied in the direction of grinding devices, grinding tools, grinding machine tools, etc., can solve the problem of low processing efficiency of grinding tools, and achieve the effect of high-efficiency plastic domain processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

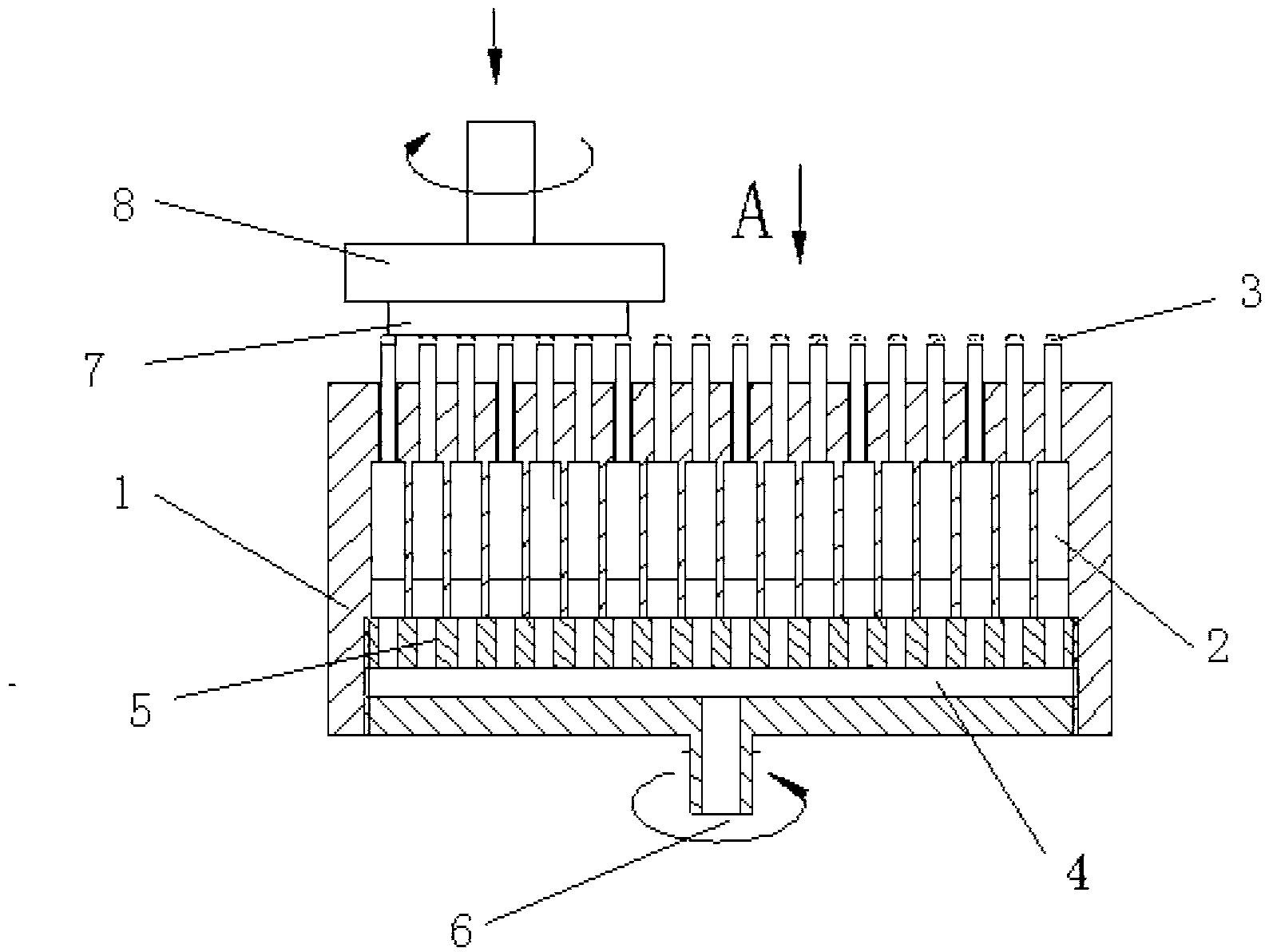

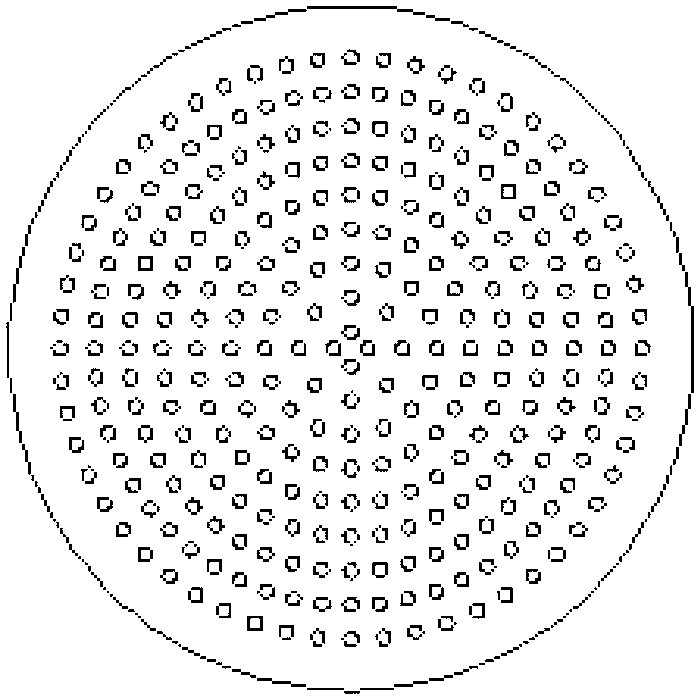

[0027] refer to figure 1 with figure 2 , an air-floating pellet abrasive device, including a disc body 1, a cutter bar 2, a diamond pellet 3 and an air cavity 4, the disc body 1 is a circular structure, and the disc body 1 is provided with the disc body 1 The center of the circle is the center of the multi-layer ring arrangement to assemble the air cavity hole of the cutter bar 2 with equal diameter and the air cavity 4 communicating with the compressed air 6; the cutter bar 2 is arranged and installed in the air cavity hole , the front end of the cutter bar 2 is bonded with the diamond pellets 3 of equal diameter; the tail end of the cutter bar 2 is installed in the air cavity hole and communicates with the air cavity 4 to form a piston end, The piston ends of each cutter bar communicate with each other through the air cavity 4, and the diamond pellets 3 can float up and down in the air cavity along with the cutter bar 2.

[0028] Further, the holes of the air cavity are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com