In-mould forming mould plate as well as preparation method and uses thereof

An in-mold forming and formwork technology, which is applied in the field preparation and construction of formwork/formwork components and building components, can solve the problems of inability to further improve mechanical strength and low cost, and achieve high construction efficiency, low cost, Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Injection molded formwork is used for pouring concrete in building construction projects. The working surface of the formwork is flat and the back is provided with reinforcing ribs.

[0057] The multi-layer glass fiber web of pre-impregnated polypropylene uses the multi-layer fiber web of surface pre-impregnated polypropylene produced by Liaoning Jieshijie New Material Co., Ltd., the thickness is 0.4mm, and the glass fiber content is 30% of the overall weight.

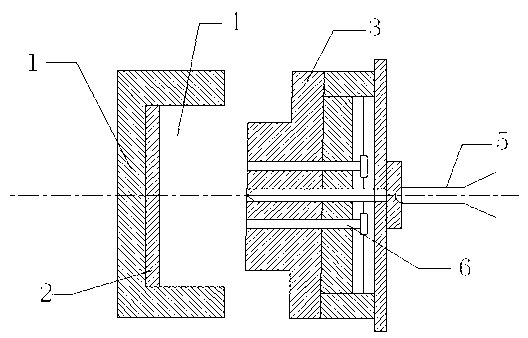

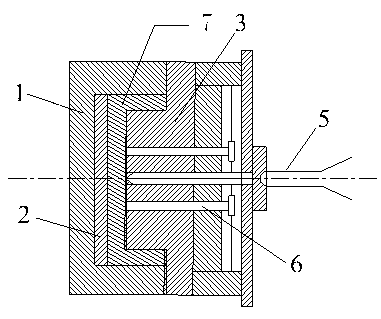

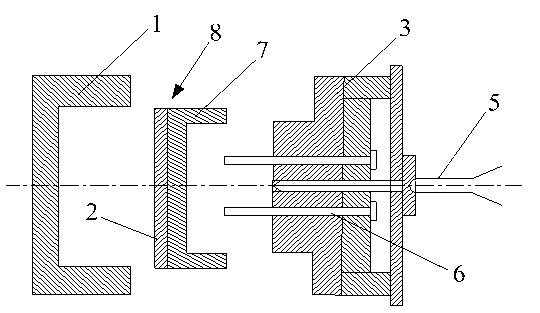

[0058] The preparation process is as follows, see Figure 1-3 The template forming process shown:

[0059] (1) Cut the multi-layer fiber web 2 with surface pre-impregnated polypropylene to the overall size of the template, and heat it in an oven for 10 minutes at a temperature of 75°C;

[0060] (2) The template mold includes a concave mold 1 and a convex mold 3. Put the heated multi-layer glass fiber mesh 2 pre-impregnated with polypropylene into the concave mold 1, and cling to the cavity 4 of the injection mo...

Embodiment 2

[0067] The working surface of the product in the injection mold is flat, there is no rib on the back, and the product is processed into a cuboid flat plate. Formwork is used to pour concrete in building construction works.

[0068] The multi-layer glass fiber mesh with surface pre-impregnated polypropylene uses the multi-layer glass fiber mesh with surface pre-impregnated polypropylene produced by Liaoning Jieshijie New Material Co., Ltd., the thickness is 0.2mm, and the glass fiber content is 50% of the overall weight.

[0069] (1) Cut the multi-layer glass fiber mesh with surface pre-impregnated polypropylene to the product size, and heat it in the oven for 20 minutes, and the oven temperature is 80°C;

[0070] (2) Put the heated multi-layer glass fiber mesh pre-impregnated with polypropylene into the mold cavity, close to the cavity of the injection mold, and the exhaust blocks are evenly distributed on the cavity, when the surface is pre-impregnated with polypropylene Whe...

Embodiment 3

[0076] The front of the product in the injection mold is arc-shaped, and the back has no reinforcing ribs. The formwork is used for pouring concrete in building construction projects.

[0077] The multi-layer glass fiber mesh with surface pre-impregnated polypropylene uses the multi-layer glass fiber mesh with surface pre-impregnated polypropylene produced by Liaoning Jieshijie New Material Co., Ltd., the thickness is 0.3mm, and the glass fiber content is 50% of the overall weight.

[0078] (1) Cut the multi-layer glass fiber mesh with surface pre-impregnated polypropylene to the product size, and heat it in an oven for 15 minutes at a temperature of 85°C;

[0079] (2) Put the heated multi-layer glass fiber mesh pre-impregnated with polypropylene into the mold cavity, close to the cavity of the injection mold, and the exhaust blocks are evenly distributed on the cavity, when the surface is pre-impregnated with polypropylene When the multi-layer glass fiber mesh sticks to the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com