Method for providing a coating layer with protection and thermal conductivity

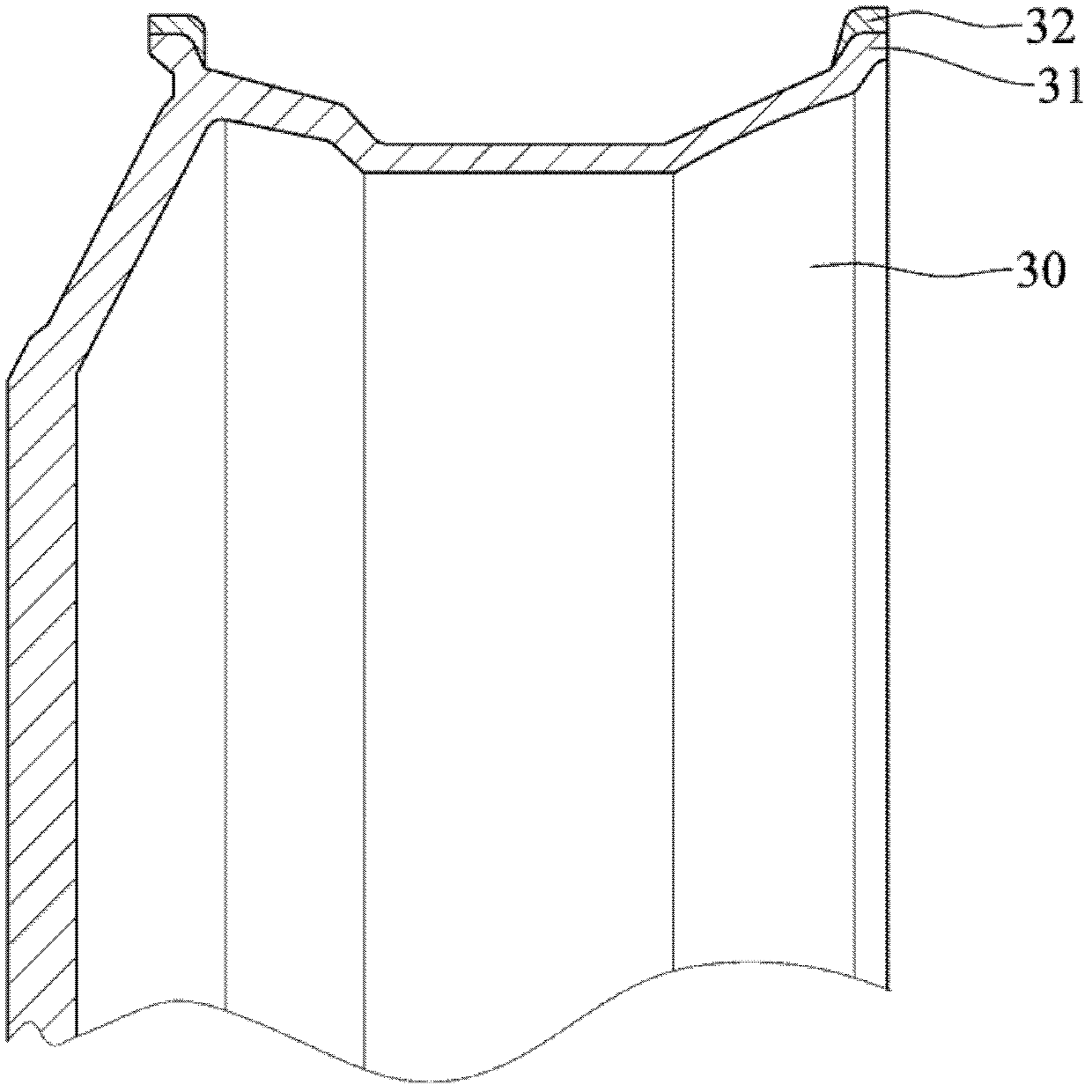

A heat-conductive and protective technology, applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of accelerating rim, rim damage, coating not applied, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

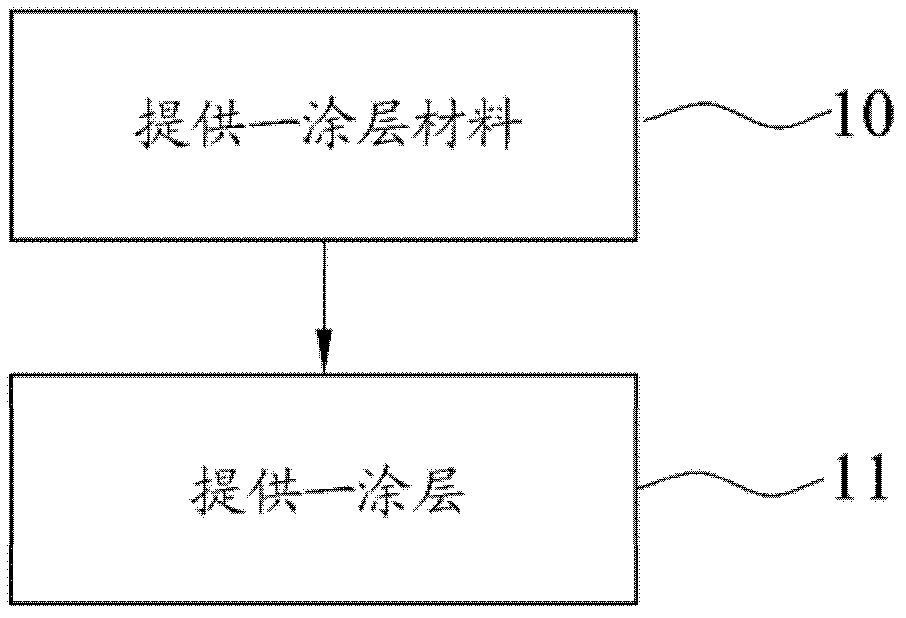

[0029] Please cooperate with reference figure 1 As shown, the present invention is a method of providing protective and thermally conductive coatings, the steps of which include:

[0030] Provide a coating material 10, the coating material is a pottery gold powder or a sintered powder;

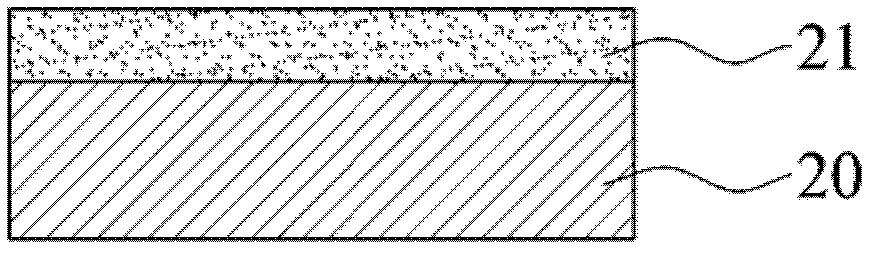

[0031] Ceramic gold powder is a mixture of metal-coated ceramic powder and metal powder. The ceramic powder is aluminum oxide, titanium oxide, chromium oxide, titanium carbide, boron carbide, chromium carbide, silicon carbide, aluminum nitride, titanium nitride, nitrogen One of boron or titanium boride or a combination of at least any two of the foregoing, so the ceramic powder is one of oxides, carbides, nitrides or borides or a combination of at l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com