Underground prefabricated pump station

An underground, pumping station technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of easy corrosion of the concrete pool wall, large area of the pump pit, long construction period, etc., to save operating costs and The effect of low maintenance cost, infrastructure cost and short installation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

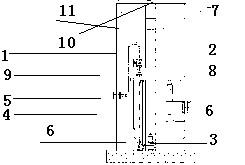

[0021] A buried prefabricated pumping station of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] The present invention is a buried prefabricated pumping station, which consists of a prefabricated glass fiber reinforced plastic cylinder (1), a crushing grid (2), a water pump (3), a water pump coupler (4), a liquid level control system (5), and an automatic The cleaning device (6), the ladder (7), the water inlet pipe (8), the water outlet pipe (9), the ventilation pipe (10) and the control box (11) are composed. The crushing grid (2), water pump (3), water pump coupler (4), liquid level control system (5), cylinder bottom self-cleaning device (6), and ladder (7) are located in the prefabricated glass fiber reinforced plastic cylinder (1), The ventilation pipe (10) is located on the top of the prefabricated FRP cylinder (1), the control box (11) is located on the upper side of the prefabricated FRP cylinder (1), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com