Double heat exchange temperature control device and power generation system thereof

A temperature control device and temperature control device technology, applied in control systems, solar thermal power generation, steam generation, etc., can solve problems such as difficult steam temperature control, large temperature difference between input and output, valve damage, etc. High work efficiency and the effect of reducing production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

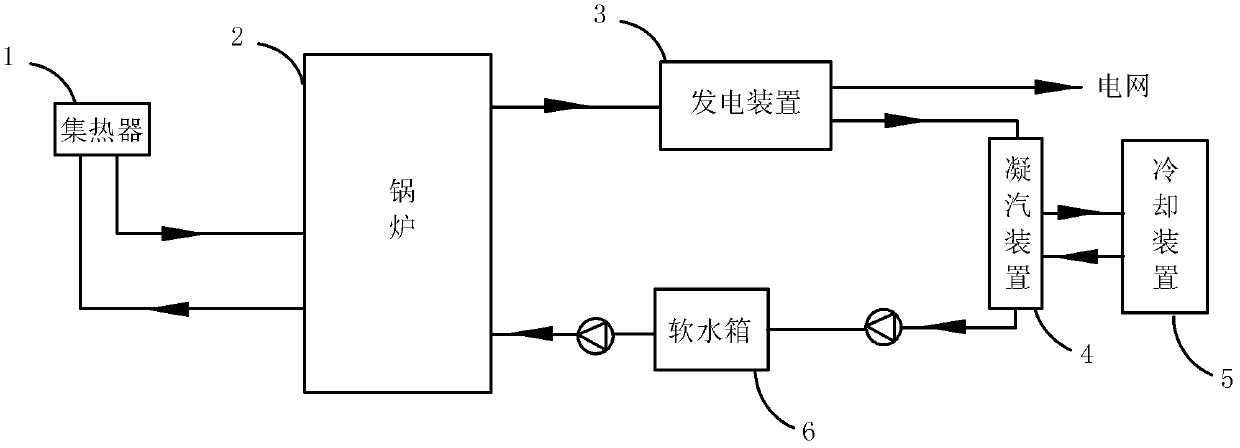

[0027] Such as figure 1 As shown, the power generation system of the double heat exchange temperature control device of the present invention includes a heat collector 1, a boiler 2, a power generation device 3, a gas condenser 4, a cooling device 5, a soft water tank 6 and a plurality of hydraulic pumps.

[0028] The solar collector 1 is heated by the solar device and transmits the high-temperature medium to the boiler 2. The steam generator in the boiler 2 generates steam to drive the power generation device 3 to generate electricity. The low-temperature medium after power generation passes through the condensing device 4, cooling device 5, soft water The tank 6 and hydraulic pumps go back into the boiler 2 . In an embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com