Method for hybrid system modeling and coordinated optimization control of blast-furnace hot blast stove

A hybrid system, coordinated optimization technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems affecting the working efficiency of the hot blast stove, improving, ignoring the integrity of the hot blast stove system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

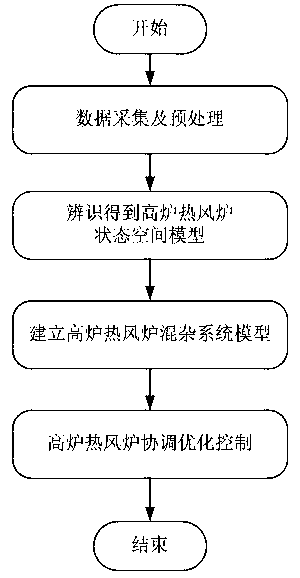

[0029] see figure 1 , the method sequence of the present invention includes the following steps: (1) data acquisition and preprocessing; (2) identifying and obtaining the state space model of the blast furnace hot blast stove; (3) establishing a hybrid system model of the blast furnace hot blast stove; (4) coordinating the blast furnace hot blast stove optimized control.

[0030] Each step is described in detail as follows:

[0031] 1. Data collection and preprocessing:

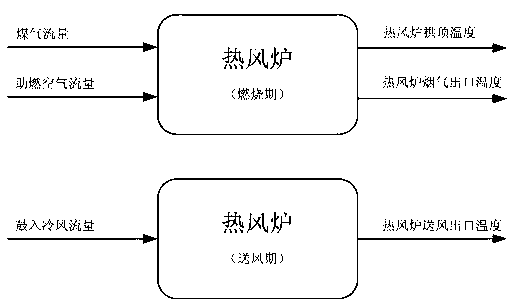

[0032] Although the structure of the blast furnace hot blast stove is different, their working principle is basically the same. A cycle of a hot stove can be divided into two working stages: the combustion period and the air supply period.

[0033] Combustion period: Blast furnace gas and air are mixed and burned in the combustion chamber to produce high-temperature flue gas. The high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com