Groove-type silicon nanocrystalline memory and manufacturing method thereof

A silicon nanocrystal and memory technology, which is applied in the field of memory, can solve problems such as deterioration of device storage characteristics, achieve changes in erasure characteristics, avoid increased edge thickness, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

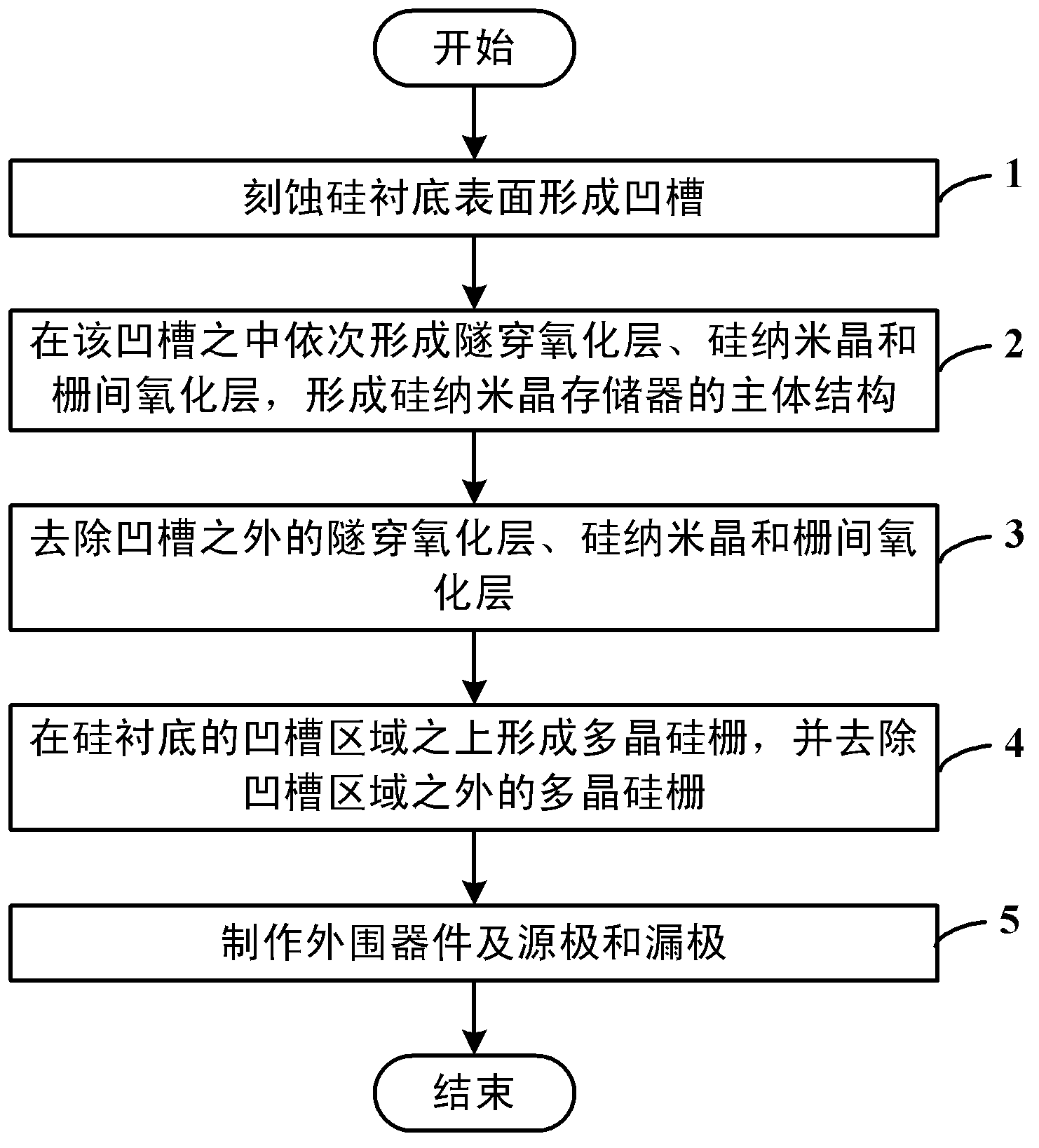

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

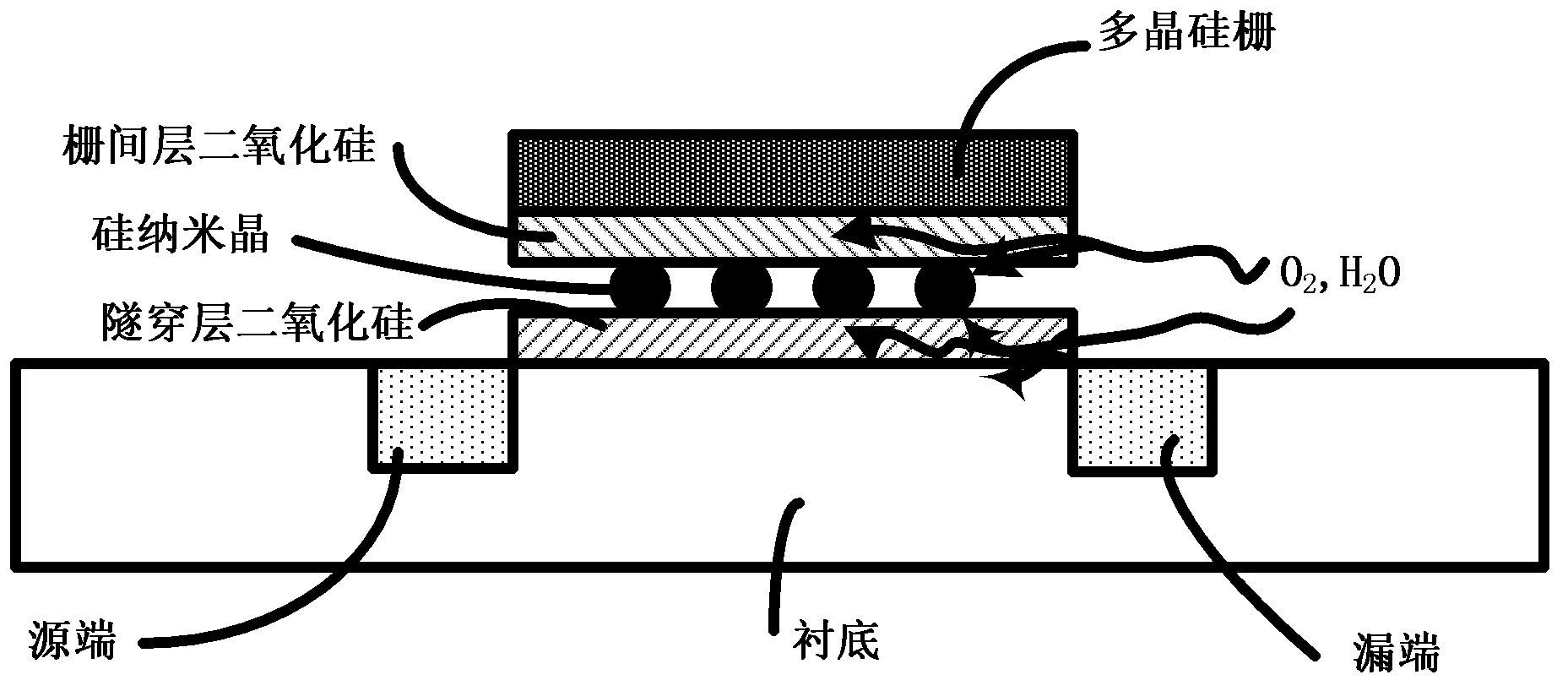

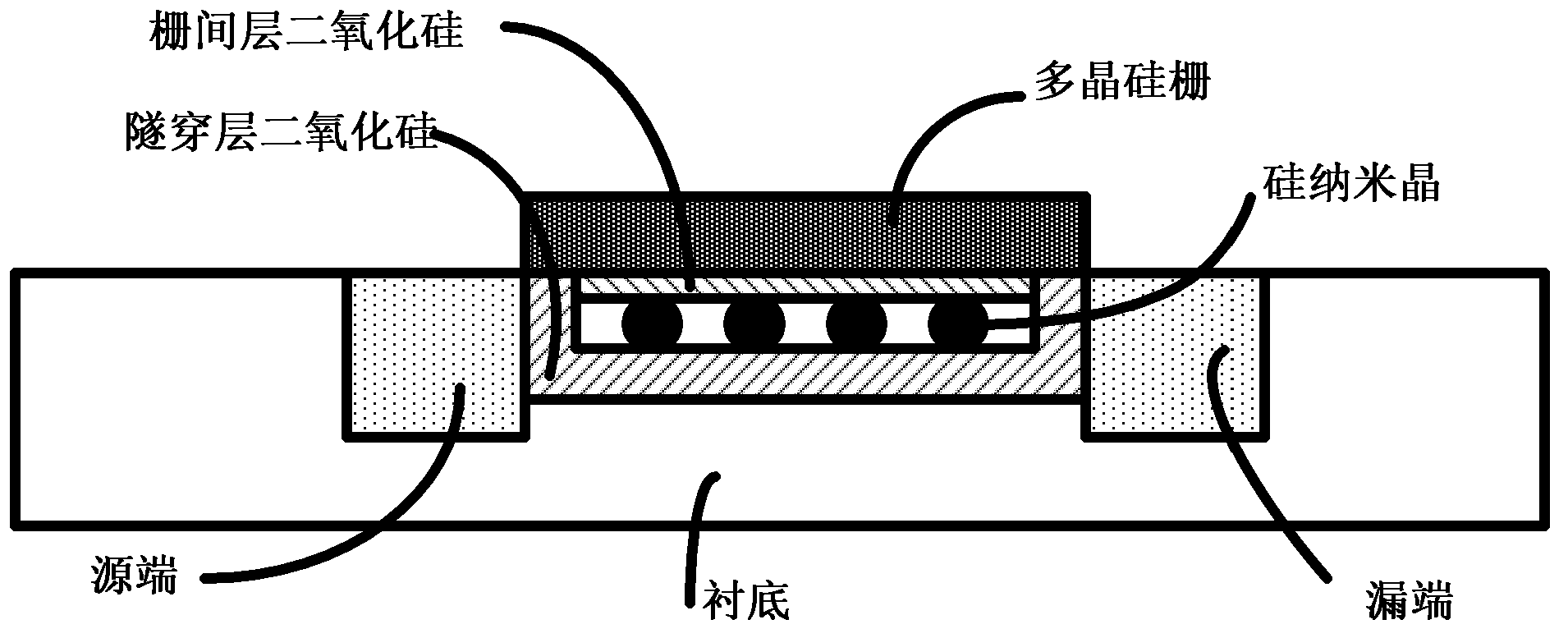

[0022] Aiming at how to thoroughly avoid the influence of the smiling face effect on silicon nanocrystal devices, the present invention adopts a grooved silicon nanocrystal device structure, so that silicon nanocrystals, tunnel oxide layers, and inter-gate oxide layers are located in the grooves, and the upper Covering the polysilicon gate, so that the silicon nanocrystals are not oxidized, and the thickness of the edge of the tunnel oxide layer will not increase, so the storage window of the device with this structure is large and the uniformity is better.

[0023] The silicon nanocrystal storage device structure provided by the invention is realized by fabricating a device on a groove on a silicon substrate. The groove i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap