Separator comprising density-controlled coating and battery comprising same

A separator and coating technology, applied in the field of separators including density-controlled coatings and batteries including the separators, can solve the problems of deterioration of separator adhesion, difficulty in preventing short circuits, and reduced coating force, and achieve excellent prevention, The effect of increasing the service life and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

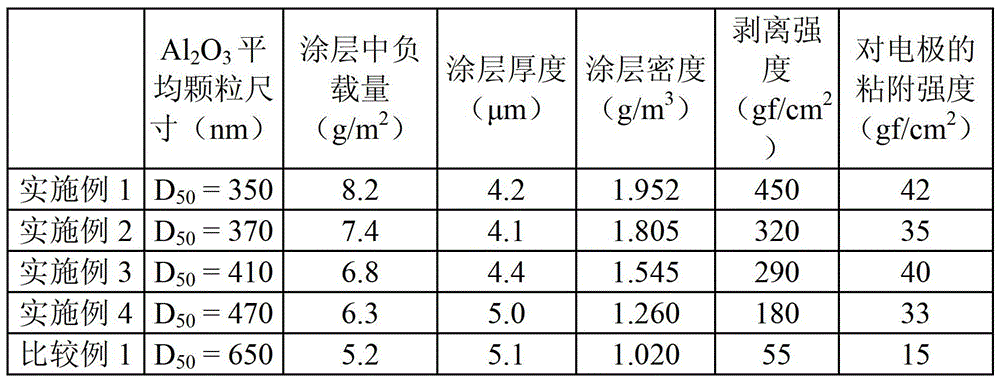

Embodiment 1 to 4

[0096] Including the weight average molecular weight 1,000,000g / mol The above polyvinylidene fluoride homopolymer and average particle size are 700nm The following inorganic particles and the density is 1.2g / m 3 Preparation of the above coated diaphragm

Embodiment 1

[0098] (1) Preparation of coating agent

[0099] 1) Add polyvinylidene fluoride-hexafluoropropylene (PVdF-HFP) copolymer (21216, Solvay) with a weight average molecular weight of 700,000 g / mol to acetone (Daejung Chemicals & Metals), add 10wt%, and stir The reactor was stirred at 25°C for 4 hours to prepare the first polymer solution,

[0100] 2) Add a polyvinylidene fluoride ("PVdF") homopolymer (5130, Solvay) with a weight average molecular weight of 1,100,000 g / mol to DMF (Daejung Chemicals & Metals), the addition amount is 10wt%, and then use a stirrer at 25 Stir at °C for 4 hours to prepare the second polymer solution,

[0101] 3) Put Al 2 O 3 The particles (LS235, Nippon Light Metal, Ltd.) were added to acetone (Daejung Chemicals & Metals) in an amount of 25wt%, and then ground and dispersed with a bead mill at 25°C for 3 hours to prepare an inorganic dispersant.

[0102] Mix the prepared first polymer solution, second polymer solution and inorganic dispersant in the following ...

Embodiment 2

[0106] The separator was prepared in the same manner as in Example 1, except that the inorganic particles were dispersed for 2 hours to prepare the inorganic dispersant in (1) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com