Self-heating microfluidic chip

A microfluidic chip, self-heating technology, used in heating or cooling equipment, laboratory utensils, laboratory containers, etc., can solve problems such as expensive, affecting the promotion of microfluidic chips, complex peripherals, etc. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1 A self-heating microfluidic chip

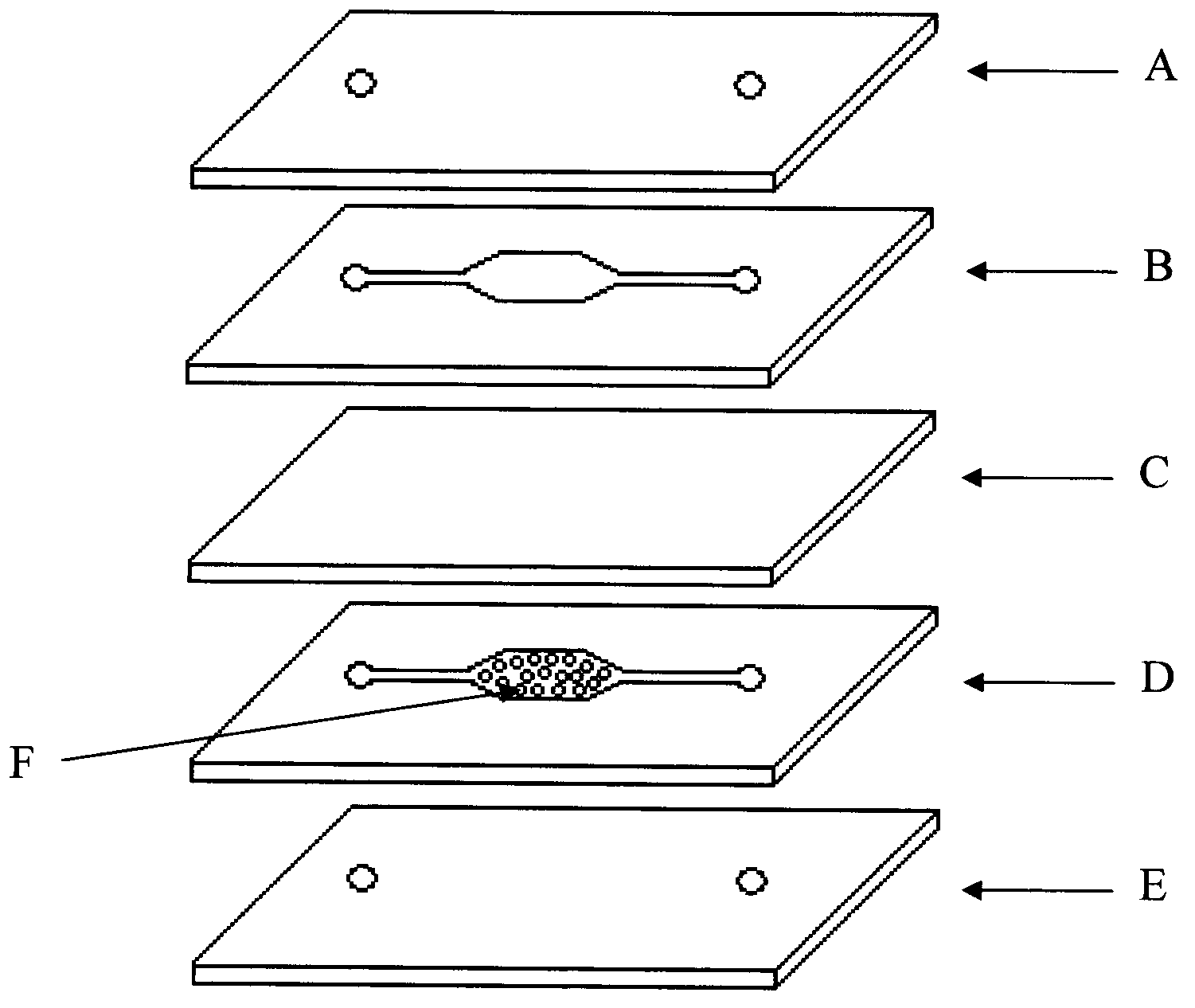

[0014] A self-heating microfluidic chip is prepared from polymethyl methacrylate. like figure 1 As shown, the chip has a five-layer structure, in which the thickness of the cover layer is 1mm, and a fluid inlet and outlet with a diameter of 3mm is processed; the thickness of the microfluidic layer is 0.5mm, and hollowed out microfluidic channels and chambers are processed; the middle heat transfer layer is blank Polymethyl methacrylate film with a thickness of 0.1mm; self-heating layer with a thickness of 0.5mm, processed with the same hollow structure as the microfluidic layer, filled with calcium oxide microspheres with a particle size of 200μm; the base layer with a thickness of 1mm, processed with a diameter The 3mm fluid inlet and outlet provide channels for water to flow in and fill the entire self-heating layer and have an exothermic reaction with the calcium oxide filler. The five-layer structure is aligned and stac...

Embodiment 2

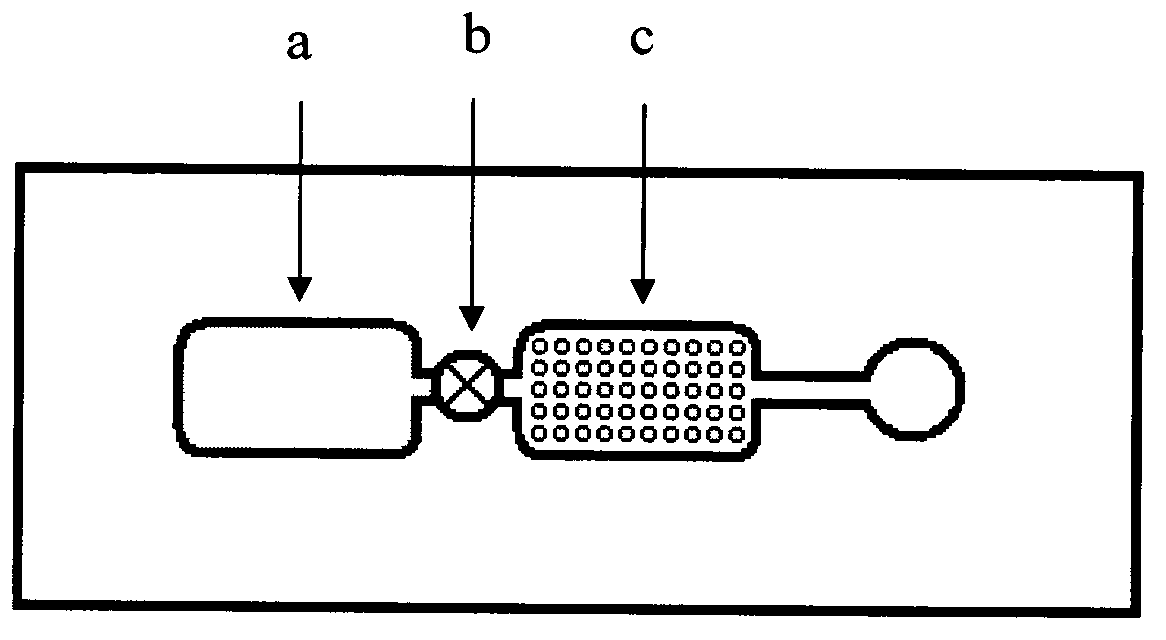

[0015] Example 2 A self-heating microfluidic chip with internal storage of water

[0016] A self-heating microfluidic chip is prepared from polymethyl methacrylate, and its self-heating layer structure is as follows: figure 2 As shown, the interior is stored with water and calcium oxide filler. Wherein, water is sealed in chamber a in the chip; calcium oxide microspheres are also sealed in another chamber c in the chip. The two chambers are isolated by a screw-type isolating valve b. When in use, the isolating valve is opened, and water flows into the calcium oxide chamber to undergo an exothermic reaction, thereby realizing self-heating of the microfluidic chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com